Table of Contents:

- Introduction to Plastic Molding

- Preparing for Plastic Molding

- Plastic Molding Processes

- Operating a Plastic Molding Factory

- Cost and Efficiency Considerations

- Industry Trends and Innovations

- Conclusion

-

1.Introduction to Plastic Molding

Plastic molding is the process of shaping plastic materials into specific forms through the use of specialized tools, equipment, and techniques. This is a versatile manufacturing process that can produce a wide range of plastic products used in diverse industries such as automotive parts, medical equipment, and consumer goods.

Advantages of Plastic Molding:

One of the primary advantages of plastic molding is its versatility. The process can be used with a wide variety of plastic materials, including thermoplastics, thermosets, and elastomers. Plastic molding is also highly efficient, capable of producing large quantities of products quickly and at a relatively low cost. Additionally, plastic molding provides flexibility in design and manufacturing, resulting in a wide range of product shapes, sizes, and configurations.

Types of Plastic Molding:

There are several types of plastic molding, including:

- Injection Molding: This is the most common type of plastic molding, involving the injection of molten plastic material into a mold cavity. This process is used for producing high-volume, complex, and precise plastic parts with exceptional accuracy.

- Blow Molding: This involves the use of a mold that is inflated with air to create hollow plastic parts. Blow molding is primarily used for creating bottles, containers, and other similar products.

- Rotational Molding: This is a technique that involves slowly rotating a mold filled with plastic material as it is heated. The resulting products tend to be lightweight, with uniform thickness, and are ideal for producing large items such as tanks, containers, and playground equipment.

Other types of plastic molding include extrusion molding, compression molding, and transfer molding, each with its own unique advantages and applications.

-

2.Preparing for Plastic Molding

Before starting the plastic molding process, it’s important to take the necessary steps to prepare the design, materials, and mold type.

- Designing the Product:

The first step in preparing for plastic molding is designing the product. Product design plays a crucial role in determining the success of the final product. Designers must create a 3D model of the product using computer-aided design (CAD) software to provide the necessary geometrical details. The design must take into account the specific requirements of the product, such as the desired strength, durability, and functionality. - Choosing the Right Material:

The selection of the right material is critical for successful plastic molding. Different materials have varying properties and performance characteristics that will impact the final product quality. Factors to consider when selecting materials include durability, stiffness, heat resistance, chemical resistance, and cost, among others. Once you have identified the desired material, it’s essential to source it from reputable suppliers to ensure the required quality. - Determining the Mold Type:

The next step in preparing for plastic molding is determining the mold type. There are several types of molds available, and each is suited to a specific type of plastic molding. Some of the popular types of molds include injection molds, blow molds, and rotational molds. The mold should be made of a material that is strong, durable, and capable of producing the necessary geometrical details.

By taking the above steps when preparing for plastic molding, manufacturers can minimize the chances of defects, ensure product quality, and save costs in the long run.

-

3.Plastic Molding Processes

There are different types of plastic molding processes that are used depending on the product design, size, and functionality. Some of the most common plastic molding processes include Injection Molding, Blow Molding and Rotational Molding.

- Injection Molding:

Injection Molding is the most commonly used process for manufacturing plastic parts, producing a variety of high-volume items such as automotive parts, electronic housings, and household products. It involves injecting melted plastic material into a mold cavity, where it cools and solidifies to form the final product. Injection molding is highly efficient and precise, allowing for complex geometries and tight tolerances. - Blow Molding:

Blow molding is a process used to manufacture hollow objects like bottles, containers, and tanks. The process involves melting plastic material and shaping it into a tube or parison. The parison is then transferred to a mold, where it is inflated to form the desired shape. Blow molding is used to produce high volumes of products with consistent wall thickness, which is essential in the production of liquid or gas storage containers. - Rotational Molding:

Rotational molding or rotomolding is a process that involves rotating a hollow mold at high temperatures and filling it with molten plastic materials. The material cools and solidifies into the desired shape, producing items such as storage tanks, playground equipment, and furniture. The process is highly versatile, allowing for the production of large and complex shapes, and is ideal for low-volume or limited-run productions.

Other types of plastic molding processes include thermoforming, extrusion molding, compression molding, and transfer molding, each with their unique benefits and applications. By selecting the appropriate plastic molding process, manufacturers can achieve the desired product quality, efficiency, and production rate.

-

4.Operating a Plastic Molding Factory

To run a successful plastic molding factory, manufacturers must maintain high standards of equipment, tools, quality control measures, and safety. Here are some of the key considerations when operating a plastic molding factory:

- Equipment and Tools:

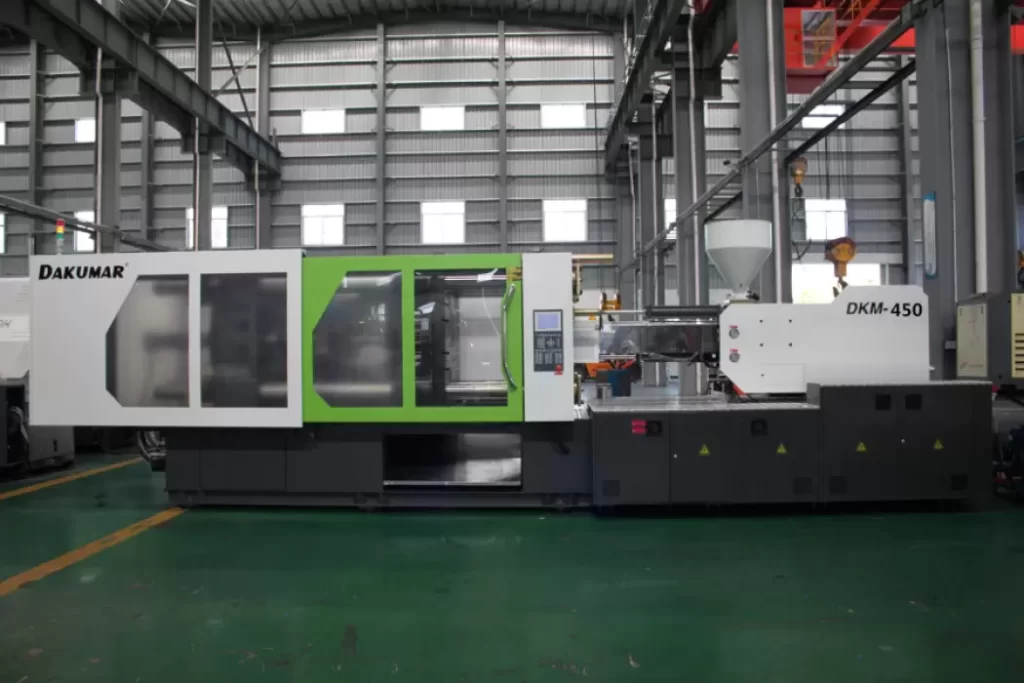

Plastic molding requires specialized equipment and tools that are designed to meet the specific requirements of the production process. Essential equipment includes Injection molding machines, mold cleaning and maintenance equipment, and conveyors. The tools include molds, cutters, and auxiliary equipment. It is crucial to ensure that the equipment and tools are regularly maintained and replaced when necessary. - Quality Control Measures:

Maintaining high-quality production output is essential in plastic molding. Quality control measures include monitoring the injection pressure, temperature and time, flow rate, and other process parameters. Also, implementing visual inspections at various stages of production, such as post-molding inspection, to detect the presence of any defects. Quality control measures can help identify and correct defects early in the production process, minimizing waste, and increasing production yield. - Safety Precautions:

Operating a plastic molding factory can present a range of potential health and safety hazards for workers and the factory environment. Workers may be exposed to hazardous chemicals, excessive noise levels, and moving machinery. As such, it is important to implement and enforce strict safety protocols, including the use of personal protective equipment, regular training, equipment maintenance, and appropriate handling of hazardous materials. It’s also necessary to conduct regular audits to identify areas of risk and to eliminate or mitigate potential hazards.

By following best practices for equipment and tool maintenance, quality control measures, and safety precautions, plastic molding manufacturers can improve their overall operations, ensure product quality, and protect the health and safety of their workers.

-

5.Cost and Efficiency Considerations

When operating a plastic molding factory, it is essential to consider cost and efficiency to achieve profitability while maintaining product quality. Here are some key cost and efficiency considerations:

- Factors Affecting Production Costs:

Several factors can influence production costs, including labor costs, raw material costs, energy consumption, maintenance, and machinery costs. It is important to carefully monitor and manage these costs to minimize waste and maximize efficiency. - Sustainable Manufacturing Practices:

Sustainable manufacturing practices are becoming increasingly popular and can help in reducing costs while promoting environmental responsibility. Investing in energy-efficient machinery, using recyclable materials, and implementing sustainable practices such as reducing waste can help in reducing costs and improving efficiencies. - Maximizing Efficiency and ROI:

To maximize efficiency and Return on Investment, manufacturers can optimize their production processes, minimize waste, implement preventative maintenance, and make use of process data to identify and tackle inefficiencies. Regular audits and analyses can provide insights into areas for improvement, which can be acted on to increase production efficiency and yield.

In conclusion, achieving profitability in plastic molding manufacturing requires careful cost and efficiency considerations. By managing production costs, adopting sustainable manufacturing practices, and maximizing efficiency and ROI, manufacturers can keep their factories running efficiently, minimize waste and downtime, and produce high-quality products that meet customer requirements.

-

6.Industry Trends and Innovations

To remain competitive in the plastic molding industry, it is essential to keep up with the latest trends and innovations. Here are some of the industry trends and innovations worth following:

- The Rise of Additive Manufacturing:

Additive manufacturing, also known as 3D printing, has become increasingly popular in recent years. This innovative technology allows for the creation of complex geometries and customized designs while reducing lead times and minimizing material waste. Additive manufacturing is still at an early stage, but it has significant potential to reshape the plastic molding industry in the future. - Integrating Smart Technologies:

The integration of smart technologies such as Internet of Things (IoT), robotics, and artificial intelligence (AI) is increasingly becoming more widespread across various industries, including plastic molding. The use of these technologies can improve production efficiency, reduce maintenance costs, and enhance safety measures. - The Future of Plastic Molding:

The future of plastic molding is bright, with several innovations currently in development to improve production efficiency and product quality. These include the use of recycled and environmentally friendly materials, advanced multi-material molding techniques, and integration with Industry 4.0 technologies for production line automation and optimization.

As the industry continues to develop, manufacturers must remain knowledgeable about emerging trends and innovations, adopting best practices to remain competitive, and positioning their businesses for growth in the future.

More about Plastic Molding information,You can click on the V1 Prototype website to find it.

-

7.Conclusion

Plastic molding is an essential process for manufacturing plastic products across different industries. It allows for versatility, precision, and efficiency in creating a wide range of shapes, sizes, and configurations. Operating a plastic molding factory requires careful consideration of equipment, quality control, safety measures, cost, and efficiency factors. Manufacturers must also keep up with emerging industry trends and innovations to remain competitive and position their business for growth in the future.

Recap of Key Points:

- Plastic molding is a versatile, efficient, and precise process for manufacturing plastic products.

- Designing the product, choosing the right material, and determining the mold type are essential preparation steps before plastic molding.

- Injection molding, blow molding, and rotational molding are the most common types of plastic molding.

- Equipment and tool maintenance, quality control measures, and safety precautions are essential in plastic molding operations.

- Managing production costs, adopting sustainable practices, and maximizing efficiency are crucial for profitability.

- The rise of additive manufacturing, smart technologies integration, and multi-material molding are key trends and innovations in the plastic molding industry.

Final Thoughts and Recommendations:

Operating a plastic molding factory can be complex, but with the right preparation, equipment, and management, it can be highly rewarding. To succeed, it’s essential to prioritize quality control, cost management, and efficiency throughout the production process. Keeping up with emerging industry trends and innovations and integrating them into your business practices can also help keep your operations viable and competitive in the long run.