Table of Contents:

- Introduction

- Types of Plastic Molding Die

- Applications of Plastic Molding Die

- Design and Manufacturing of Plastic Molding Die

- Maintenance of Plastic Molding Die

- Troubleshooting Common Issues in Plastic Molding Die

- Advancements in Plastic Molding Die Technology

- Conclusion

-

1.Introduction

Plastic molding die is an essential tool used in the manufacturing industry to produce plastic products of various shapes and sizes. It is a precision tool that enables the production of high-quality plastic products that are used in various industries, including automotive, consumer goods, medical, and packaging industries. This article provides an in-depth understanding of plastic molding die, including its types, applications, design, maintenance, troubleshooting, and advancements in technology.

-

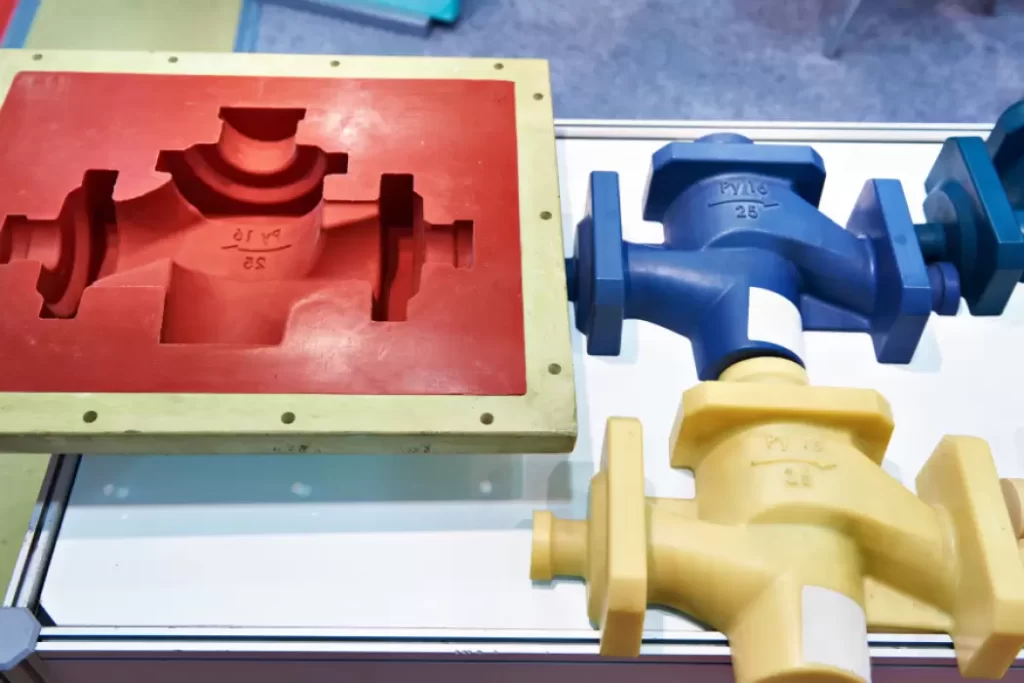

2.Types of Plastic Molding Die

There are several types of plastic molding die, each of which is suitable for different applications. The most common types include injection molding die, blow molding die, compression molding die, and transfer molding die.

Injection molding die is the most widely used type of plastic molding die. It is used to produce complex shapes and intricate parts. The process involves injecting molten plastic material into a mold cavity, which is then cooled and solidified. This type of die is used in the production of various products, including automotive parts, medical devices, and consumer goods.

Blow molding die, on the other hand, is used to produce hollow objects, such as bottles, containers, and jars. The process involves blowing compressed air into a molten plastic tube, which is then shaped into the desired shape using a mold cavity. This type of die is used in the packaging industry, where it is used to produce bottles, containers, and other packaging materials.

Compression molding die is used to produce parts with uniform thickness and high strength. The process involves compressing a pre-heated plastic material into a mold cavity using high pressure and temperature. This type of die is used in the production of automotive parts, electrical components, and other industrial products.

Transfer molding die is used to produce small and complex parts that require high precision and accuracy. The process involves transferring a pre-heated plastic material into a mold cavity using a plunger or piston. This type of die is used in the production of electronic components, medical devices, and other precision parts.

-

3.Applications of Plastic Molding Die

Plastic molding die is used in various industries to produce a wide range of products. The automotive industry is one of the largest users of plastic molding die, where it is used to produce various parts, including dashboard components, bumpers, and door handles. The consumer goods industry also uses plastic molding die to produce products such as toys, kitchen utensils, and electronic devices. The medical industry uses plastic molding die to produce medical devices, such as syringes, catheters, and implants. The packaging industry also uses plastic molding die to produce packaging materials, such as bottles, containers, and jars.

Click on the V1 Prototype website to gain more information.

-

4.Design and Manufacturing of Plastic Molding Die

The design and manufacturing of plastic molding die involve several factors, including design considerations, material selection, and manufacturing processes. The design considerations include the complexity of the part, the material used, and the production volume. Material selection is critical in determining the quality and durability of the die. The manufacturing process involves several stages, including die casting, machining, and finishing.

-

5.Maintenance of Plastic Molding Die

Regular maintenance is critical in ensuring the longevity and efficiency of plastic molding die. The maintenance process involves cleaning and inspection, repair and replacement, and preventive maintenance. Cleaning and inspection are necessary to identify any defects or damages that may affect the performance of the die. Repair and replacement are necessary to fix any defects or damages identified during the inspection process. Preventive maintenance involves regular cleaning, lubrication, and replacement of worn-out parts.Troubleshooting Common Issues in Plastic Molding Die:

Several issues may arise during the production process, affecting the quality and efficiency of plastic molding die. Some common issues include warping, flashing, short shot, sink marks, and burning. Warping occurs when the part is not cooled uniformly, resulting in uneven shrinking and deformation. Flash occurs when excess material seeps out of the mold cavity, resulting in an unwanted protrusion. Short shot occurs when the mold cavity is not filled entirely, resulting in an incomplete part. Sink marks occur when the surface of the part is not uniform due to uneven cooling, resulting in depressions or sink marks. Burning occurs when the material is overheated, resulting in a burnt appearance on the surface of the part. Troubleshooting these issues involves identifying the cause and implementing corrective measures, such as adjusting the temperature, pressure, or cooling time.

-

6.Advancements in Plastic Molding Die Technology

Advancements in technology have led to the development of new techniques and tools for the design, manufacturing, and maintenance of plastic molding die. 3D printing technology has revolutionized the manufacturing process, enabling the production of complex and intricate designs with high precision and accuracy. Digital twin technology has also enabled the simulation and optimization of the die design, reducing the time and cost required for the production process.

-

7.Conclusion

Plastic molding die is an essential tool in the manufacturing industry, enabling the production of high-quality plastic products used in various industries. Understanding the types, applications, design, maintenance, and troubleshooting of plastic molding die is critical in ensuring the efficiency and longevity of the tool. Advancements in technology have also enabled the development of new techniques and tools, improving the quality and efficiency of the production process. With continued research and development, plastic molding die technology is set to revolutionize the manufacturing industry, enabling the production of new and innovative products that meet the demands of a rapidly changing market.