High-Quality screws and barrels for plastic Injection machinery

For exceptional plastic injection molding results, trust our high-quality screws and barrels. Engineered for longevity and precision, our machinery components ensure superior performance and productivity in your manufacturing process.

Screw & Tube Material type for Plastic Machinery

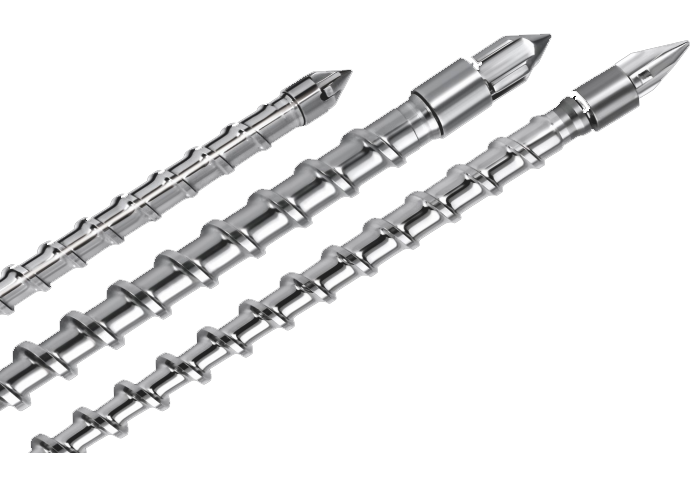

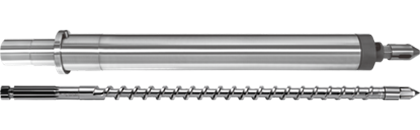

Optical special screw

Imported alloy tool steel / high-speed steel as raw materials, through the overall vacuum quenching, secondary tempering heat treatment, combined with "full hardness without school point" processing technology overall hardness HRC: 60 ~ 63 degrees. Make its steel play a strong wear resistance..

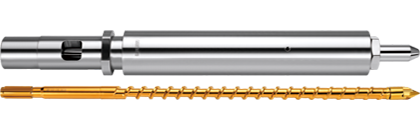

Alloy Grade B screw

The product thickness is thin, strong, easy to release, high yield, does not affect the imaging effect of high-speed dome camera, the picture accuracy rate is high, the image is clear, with high depth, distortion, high transmission rate and many other advantages

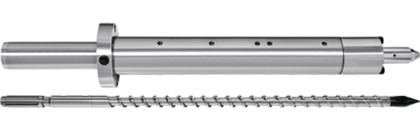

Universal top screw

Powder high speed steel and powder stainless steel, is the world's top industrial tool steel using powder cure method (atomized powder in the hot state for isostatic pressure treatment) HIP to produce dense billets, uniform organization, fine grain size...

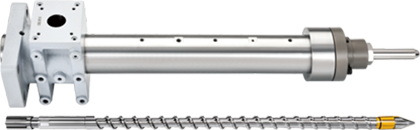

Clad alloy screw

The base material is made of high toughness and high hardness steel, and the surface of the screw is made of Ni-based, Ni+WC alloy powder fusion injection technology from the United States, which makes the working area of the screw alloy full cloak, with a thickness of 1~2mm and a bonding strength of about 210 bar...

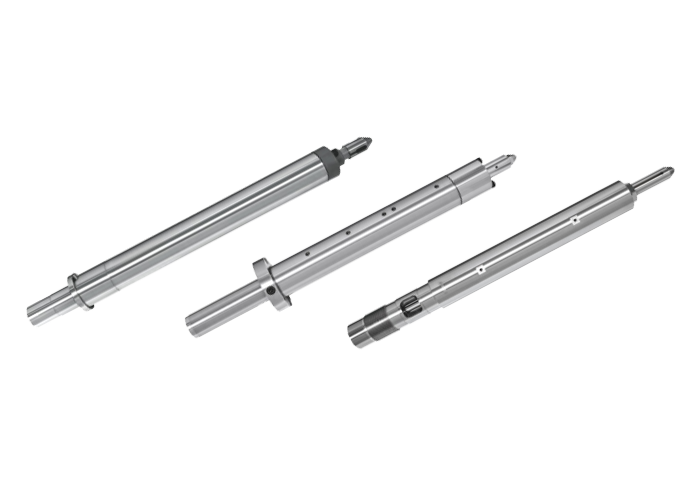

Nitriding screw/tube

High quality nitriding steel SACM645 or SKD61 is used for surface vacuum nitriding treatment after quenching, and the nitriding furnace is developed and improved to distribute the gas evenly in the furnace by means of leaf fan agitation...

Alloy material tube

Double alloy material tube is a layer of 2~3mm alloy powder casted in the inner hole of the material tube by high temperature centrifugal casting to enhance the wear resistance, corrosion resistance and high temperature resistance of the inner hole...

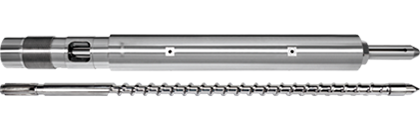

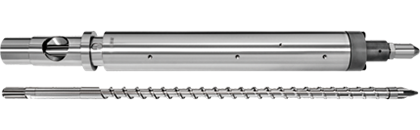

Screw & Tube for different Injection Molding Machine

Sodick Machine screw

Sumitomo machine screw

Taizhong machine screw

Fanuc machine screw

Multiplas Machine screw

Toyo machine screw

Nissei machine screw

JSW machine screw

Screw & Tube Accessories

Non-standard customization

Screw Accessories

Tube Fittings

V1 screws and barrels Services

V1 is engaged in the production and manufacturing of high-quality screws and tubes for plastic machinery. It has professional R&D design, production technology, production quality control and technical service teams, advanced processing equipment at home and abroad, and sincere cooperation with internationally renowned steel manufacturers and large heat treaters. Strict material selection and strict control of heat treatment processing technology.

Our customer base comes from plastic machinery manufacturers and plastic product manufacturers from all over the world. We have formed long-term cooperation with many domestic and foreign listed companies. We rely on our established social status in plastic machinery accessories and our excellent professional team to solve usage problems for our customers. various problems to make plastic molding more efficient and stable.

Qualification Certificate: ISO9001:2015; ISO14001:2015; IATF16949:2016.

FAQ in Screws And Barrels For Machinery

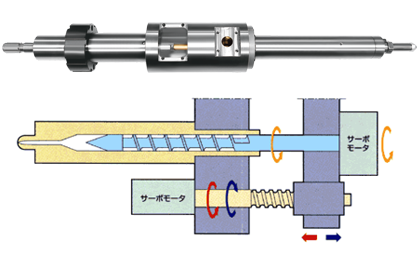

Screws and barrels are key components in plastic injection machinery. The screw is a threaded metal rod that rotates within the barrel. Together, they work to melt, mix, and convey plastic materials during the injection molding process.

Screws and barrels play a critical role in achieving efficient and consistent plastic melting, homogenization, and controlled injection. They ensure proper plasticizing, melting, and conveying of the material, resulting in high-quality and uniform molded products.

Screws and barrels influence various parameters of the injection molding process, such as melt temperature, melt quality, shot size, and injection speed. The design, geometry, and surface treatment of screws and barrels impact the overall melt quality, part appearance, and dimensional accuracy.

Screws and barrels are typically made of high-quality alloy steels or bimetallic materials. These materials exhibit excellent wear resistance, corrosion resistance, and thermal stability, ensuring durability and longevity in demanding injection molding environments.

The lifespan of screws and barrels can vary depending on several factors, including the type of plastic material processed, processing conditions (temperatures, pressures), maintenance practices, and the overall quality of the components. Under normal operating conditions and with proper care, screws and barrels can last for thousands to hundreds of thousands of molding cycles.

Yes, screws and barrels can be customized to suit specific plastic resins, molding processes, and customer requirements. Factors such as the screw profile, flight depth, pitch, and barrel design can be tailored to optimize performance, ensuring efficient plasticizing and injection for different applications.

Regular maintenance is crucial for extending the lifespan of screws and barrels. This includes proper cleaning to remove any residual plastic, lubrication to reduce friction and wear, and periodic inspections to detect signs of wear or damage. Following the manufacturer's guidelines and recommendations is essential for effective maintenance.

Signs of wear in screws and barrels may include reduced melt quality, increased cycle time, poor part appearance (such as streaks or discoloration), excessive energy consumption, increased reject rates, or difficulty in maintaining consistent process parameters. If any of these signs are observed, it may indicate the need for replacement or refurbishment.

While some screws and barrels may be compatible with multiple machine brands, it is crucial to consult the manufacturer or supplier to ensure proper fit, performance, and compatibility. Different machine brands may have unique specifications and designs, necessitating specific screw and barrel configurations.

High-quality screws and barrels can be purchased from reputable manufacturers and suppliers of plastic injection machinery and components. It is advisable to research and select a trusted supplier with a proven track record, as they can offer reliable products that meet your specific requirements.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: [email protected]

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850