I. Introduction

A. Overview of Metal 3D Printing Systems

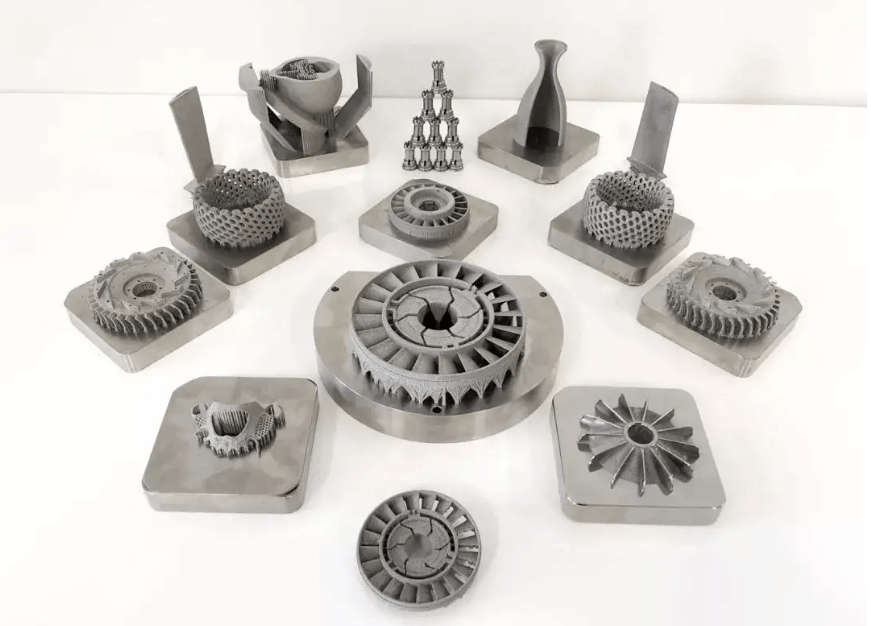

Metal 3D printing systems have revolutionized the manufacturing landscape, introducing cutting-edge technologies that enable the creation of intricate and robust metal components. Unlike traditional manufacturing methods which rely on subtractive processes like milling, turning, and grinding, metal 3D printing allows for unparalleled design freedom and complexity through an additive layer by layer process. Engineers and designers are no longer constrained by the limitations of conventional techniques and can realize even the most complex of geometries. In this guide, we will delve into the realm of metal 3D printing systems, exploring their various technologies like selective laser melting, electron beam melting and laser metal deposition. We will also look at their capabilities to produce parts from alloys like titanium, aluminum and steel with strengths and densities comparable to traditionally manufactured components. In addition, we will examine the transformative impact these systems have had on modern industries by enabling mass customization, part consolidation and accelerated product development.

B. Importance and Applications in Modern Industry

The significance of metal 3D printing systems in modern industry cannot be overstated. These systems have found applications across various sectors, from aerospace and automotive to healthcare and art. In the aerospace industry, metal 3D printing is being used to produce complex engine components with intricate internal cooling channels that improve performance and efficiency. Companies like GE Aviation have been at the forefront of qualifying additively manufactured alloy parts for critical jet engine applications. In the automotive sector, manufacturers are leveraging the design freedom of metal 3D printing to create lightweight yet strong components that improve fuel efficiency and performance. BMW and Ford have utilized the technology to print structural as well as aesthetic parts for vehicles. The ability to produce complex geometries with precision has opened new avenues for innovation and efficiency across many industries by reducing lead times, minimizing waste and enabling low-volume production of customized designs. As we navigate through this guide, we will uncover diverse applications that make metal 3D printing a cornerstone of contemporary manufacturing.

C. Objectives of the Guide

The primary objectives of this guide are to provide a comprehensive understanding of metal 3D printing systems, elucidate the various technologies involved like selective laser melting, electron beam melting and laser metal deposition, and equip readers with the knowledge needed to embark on successful metal 3D printing projects. By the end of this guide, readers should gain insights into the advantages like design flexibility and mass customization capabilities, challenges related to process optimization and quality control, and future prospects of metal 3D printing, as well as practical tips for achieving success in their endeavors. This will include understanding factors to consider for printer selection, optimization of design and print parameters, common troubleshooting techniques and real-world case studies highlighting the transformative impact of the technology.

II. Understanding Metal 3D Printing Technologies

A. Fused Deposition Modeling (FDM) for Metals

Fused Deposition Modeling (FDM) has long been associated with plastic 3D printing, but recent advancements have extended this technology to metals by developing specialized metal filaments that can be extruded through a heated nozzle. In FDM for metals, an industrial grade filament consisting of metal alloys like stainless steel or bronze is fed into a heated print head and extruded layer by layer to build a part on the print bed. We'll explore the principles behind metal FDM in more depth. The filament is heated to its melting point, typically between 250-400°C depending on the alloy, and extruded through a fine nozzle to deposit each layer. As the layers cool, they fuse together to form the final component in a process similar to plastic FDM. The key advantage of metal FDM is its lower capital investment compared to powder bed technologies, making it suitable for low to medium volume production. Applications include functional prototyping, customized fixtures and small production runs of simple parts. Understanding how FDM operates with metals is crucial for harnessing its benefits in various industries.

B. Selective Laser Melting (SLM) for Metals

Selective Laser Melting (SLM) is a powerful metal 3D printing technology that utilizes a high-powered laser to selectively melt and fuse metal powders layer by layer. In SLM, an ultra-fine laser beam typically in the infrared or ultraviolet spectrum is used to sinter metal powder particles together. A metal powder bed is created initially by spreading a thin layer of powder across the build platform using a recoater blade. The laser then traces the cross-section of the part and selectively fuses the powder particles based on a digital file. After each layer is completed, the build platform lowers and a new layer of powder is spread on top and fused to the previous layer below. This layer by layer melting results in fully dense metal parts with mechanical properties equivalent to wrought materials. SLM offers exceptional precision and surface finish with layer thicknesses as fine as 20 microns. It is suitable for printing functional end-use parts in alloys like stainless steel, tool steel, cobalt chrome and titanium. This section will delve deeper into the intricate SLM process, its advantages like design complexity and versatility offered by the process in metal printing.

C. Electron Beam Melting (EBM) for Metals

Electron Beam Melting (EBM) is another advanced technique for metal 3D printing that shares similarities to SLM but utilizes an electron beam instead of a laser as the power source. In EBM, a high-power electron beam gun is used to selectively melt and fuse metal powder layers inside a build chamber maintained at elevated temperatures, usually in excess of 1000°C. Like SLM, it involves spreading a thin layer of metal powder using a recoater, followed by fusing the powder particles based on the digital file. However, instead of a laser, an electron beam rapidly scans each layer, offering faster printing speeds. EBM also differs from SLM in its ability to 3D print in an inert, oxygen-free atmosphere using gases like argon, resulting in fully dense prints with minimal residual stresses. Common metal alloys used include titanium, cobalt-chrome and tantalum. We'll explore the intricacies of EBM in more detail, comparing it with SLM and other methods, and uncovering its applications in various industries like aerospace, medical and energy where the materials properties are highly critical.

D. Laser Metal Deposition (LMD) for Metals

Laser Metal Deposition (LMD) is a versatile metal 3D printing technology that allows for the deposition of metal layers using a high-power laser as the heat source. In LMD, a laser is focused onto a substrate where metal powder is injected through nozzles, creating a melt pool. As the melt pool solidifies, it bonds with the substrate to build up the component layer by layer. This directed energy deposition process can print fully dense parts as well as repair and coat existing components. LMD offers advantages like minimal thermal stresses during printing. It finds applications for repair, tooling and part consolidation. In this section we will unravel the working principles of LMD in more detail, exploring how the laser interacts with the powder stream to create each layer. We will also look at its diverse use cases across industries and discuss the range of metal alloy powders that are compatible with LMD like steels, super alloys and refractory metals. Understanding LMD is essential for grasping the diversity within the realm of metal 3D printing technologies.

III. Hardware and Software Considerations

A. 3D Printers and Their Capabilities

Choosing the right 3D printer is pivotal for successful metal printing projects. There are several types of metal 3D printers available based on the printing technology being utilized - powder bed fusion, directed energy deposition or material extrusion. Powder bed fusion systems like SLM and EBM printers are well suited for high precision end-use parts but have higher costs. DED systems like LMD are more versatile and suitable for repair applications. While extrusion based systems have lower costs. It is important to evaluate factors like build volume, resolution, materials supported, post-processing capabilities and intended application when selecting a printer. Other considerations include the size and budget of the organization. In this section we will explore the various metal 3D printer models available from leaders like SLM Solutions, EOS and Trumpf serving different industries like aerospace, healthcare, automotive and more. Readers will understand the advantages and limitations of each type to determine the most suitable system.

B. Metal Powders and Filaments

The choice of metal powders and filaments significantly influences the quality and characteristics of printed metal components. For powder bed systems, a wide variety of metal alloy powders are available commercially including stainless steels, tool steels, super alloys, titanium and aluminum. Aspects like powder particle size distribution, shape and flow properties impact the printing process and must be optimized. For extrusion systems, specialized metal-filled filaments have been developed containing materials like bronze and stainless steel. Even the filament diameter and material extrusion rate can impact the outcome. In this section, we will explore the various powder and filament options in more detail along with factors to consider like composition, supplier qualification when selecting the appropriate materials. The properties of the starting materials directly translate to the properties of the final printed parts.

C. Software Tools for Design and Simulation

The role of software tools in metal 3D printing extends beyond mere design. 3D CAD software is used to create digital representations of the component geometry which are then processed for 3D printing. However, additional simulation tools allow evaluating factors like support structures, stress points, temperature gradients and defect formation during printing. This enables optimization of the design and process parameters for best results. This section will provide an overview of some commonly used software. 3D CAD programs like Solidworks, Inventor and Creo allow designing complex geometries and assemblies. Tools such as Netfabb, Magics and Simufact provide options for file repair, optimization of support structures and nesting of parts on the build platform. Software suites like Autodesk Fusion 360 and Siemens NX integrate CAD, simulation and nesting. Specialized AM simulation software like Simufact Additive and Anthropic can model the layer-by-layer melting/sintering process and predict distortion or residual stresses to avoid defects. Post-processing is also aided using metrology software for first article inspection. Understanding the design and simulation tools available enables engineers to leverage the full potential of metal 3D printing for part and process development.

IV. Advantages and Challenges of Metal 3D Printing Systems

A. Speed and Customization Benefits

Metal 3D printing systems offer significant speed and customization benefits compared to traditional methods. For low to medium volume production, metal 3D printing drastically reduces the time taken to produce prototype and production parts. Complex internal features, conformal cooling channels and lattice structures that are challenging to machine can be 3D printed with ease. This allows for rapid design iteration and testing of multiple concepts early in the product development cycle. In addition, metal 3D printing is well suited for mass customization and on demand manufacturing. Complex patient-specific implants, customized prosthetics and one-off parts for defense and aerospace can be 3D printed cost-effectively in low volumes. Industries are leveraging these advantages to accelerate time to market and better meet customer needs. In this section, we will provide examples highlighting the time and cost savings achieved through metal 3D printing and its potential for mass customization applications.

B. Cost-Efficiency and Sustainability Aspects

While metal 3D printing provides clear advantages over conventional methods, it is important to evaluate the technology from a cost and sustainability perspective to ensure long term viability and adoption. Some key factors include the high initial investment required for metal 3D printers, cost of specialty metal powders and need for post-processing equipment. However, when lifecycle costs are considered, the benefits of part consolidation, less rework and flexibility outweigh the manufacturing expenses in many applications. In addition, metal 3D printing reduces material wastage significantly by only using the required material for the part without any scrap. This improves sustainability and has led OEMs to pursue green manufacturing. This section will discuss studies that have analyzed the total cost of ownership and environmental impact of metal 3D printing to provide readers with a well-rounded understanding of its viability.

C. Quality Control and Post-Processing Needs

Ensuring consistent quality of printed metal parts is essential for their structural performance and regulatory compliance. Factors like residual stresses, dimensional accuracy, density variations and surface roughness need to be controlled. Non-destructive testing (NDT) methods such as X-ray CT, ultrasonic and eddy current are used for inspection. Finishing processes like support removal, hot isostatic pressing (HIP) and heat treatment are commonly employed to enhance properties. While metal 3D printing produces near-net shape components, machining may still be required for high tolerance surfaces. Process monitoring and in-process quality control using sensors are important to track defects. Standardization of these aspects is ongoing to qualify parts for mission critical applications. This section will provide an overview of quality control and post-processing steps involved to optimize properties and achieve the desired functional specifications in metal 3D printed components.

V. Applications and Case Studies

A. Aerospace and Automotive Industries

The aerospace and automotive sectors have been at the forefront of adopting metal 3D printing due to its ability to manufacture complex lightweight structures and parts. In aerospace, critical components like turbine blades, fuel nozzles and structural brackets are being 3D printed by leaders like GE Aviation, Rolls-Royce and Airbus. Benefits include reduced part count, optimized cooling and strength. Automakers like BMW, Ford and Local Motors have utilized 3D printed aluminum and steel for chassis structures, engine components and customized vehicles. In this section, we will explore some of these real-world applications in more depth through specific case studies. For example, a case study on GE's fuel injectors highlighting the design optimization and 70% weight reduction achieved. Another case study analyzing the consolidation of 100+ parts into one for an engine bracket by an automotive OEM. Readers will gain insights on the level of part complexity and performance gains made possible with metal 3D printing.

B. Medical Device Manufacturing

The healthcare sector has wholeheartedly adopted metal 3D printing for producing customized implants, surgical guides and dental prostheses with intricate internal structures and porous surfaces. A key driver is the ability to produce patient-specific implants from medical scans with perfect fit and form. Titanium and cobalt chrome implants have improved clinical outcomes. Another major application is producing jigs and fixtures for complex surgeries using stainless steel. We will explore case studies of a customized cranial implant with integrated electronics and a 3D printed intervertebral cage with biomimetic porous architecture. The guide will illustrate how metal 3D printing has transformed medical device manufacturing from standardized to personalized solutions.

C. Art and Design Innovations

Beyond traditional industrial sectors, metal 3D printing has found diverse applications in art and sculpting by empowering creators with new forms of digital fabrication. Artists are leveraging the layer-by-layer process to envision complex designs that were previously impossible to realize. Architects are 3D printing ornate metal structures with intricate details for buildings. Jewelry designers are producing custom one-of-a-kind pieces in gold, silver and other alloys. In this section, we will showcase some examples of exquisite 3D printed metal sculptures, timepieces, architectural elements and more. Case studies will provide a glimpse into how technology and design are merging through metal 3D printing to drive new innovations.

VI. Future Prospects and Developments in Metal 3D Printing Systems

A. Emerging Technologies and Research

The field of metal 3D printing continues to evolve at a rapid pace with ongoing advancements. Researchers worldwide are developing new printing techniques with improved capabilities. Areas of focus include powder-bed fusion using dual-laser setups for increased speeds, binder jetting of metal inks capable of fine feature sizes, and extrusion of reactive metals like titanium. New materials such as superalloys, refractory alloys and multi-material systems are also being researched. Technology giants and startups alike are investing in large-scale printers for mass production. On the software front, advanced simulation tools are enabling virtual optimization before printing. This section will explore some of these emerging technologies through their working principles and potential impact on industries. Case studies on projects involving hybrid processes and new alloy systems will also be presented.

B. Potential Impact on Industries and Society

As the capabilities of metal 3D printing continue to grow exponentially, its influence on global manufacturing and business models is bound to be transformative. Mass production using these technologies could lead to decentralized localized manufacturing with distributed supply chains. On-demand digital inventory will replace warehousing. New startups are leveraging desktop metal 3D printers to provide customized, on-demand parts directly to customers. The level of customization possible will dramatically change how products are designed, marketed and serviced. Societal changes may involve new educational models to foster skills for the digital age. Increased accessibility of additive manufacturing may promote self-sufficiency and entrepreneurship. This section will discuss analyses and viewpoints on the widespread technological and socio-economic impacts of metal 3D printing.

C. Ethical and Environmental Considerations

With its growing use, ensuring responsible development and application of metal 3D printing technologies is important from an ethical and environmental standpoint. As with any emerging field, there are risks involving data security, technology control and intellectual property. Regulations are needed regarding materials qualification and part certification for safety-critical domains. Environmental impacts of powder and energy usage during printing need to be minimized through recycling and renewable energy integration. Standardization bodies are addressing these aspects through guidelines and policies. The section will raise awareness of these considerations and highlight ongoing efforts by industry and research towards developing metal 3D printing in a sustainable, regulated manner that promotes innovation responsibly.

VII. Practical Tips for Successful Metal 3D Printing Projects

A. Preparing Design Files for Metal Printing

The success of a metal 3D printing project begins with proper preparation of the digital design files. Some best practices include using a solid modeling approach with watertight surfaces, incorporating design rules like minimum wall thicknesses and radii based on process capabilities. Support structures need optimized placement and design based on part overhangs and alloys used. Orienting the part strategically can reduce build time and impact mechanical properties. This section provides specific guidelines on selecting an appropriate file format, optimizing parameters like layer thickness and orientation based on the printer and intended application. It emphasizes the importance of addressing factors like part stability, accessibility of internal features and efficiency during printing planning.

B. Optimizing Print Settings and Process Control

Fine-tuning the printing parameters is another important step to ensure optimal quality and material usage. Factors like laser power, scan speed, hatch spacing, layer thickness and atmosphere need calibrated. It may require multiple test prints. In-situ process monitoring allows catching errors early. For powder bed systems, variables involving powder distribution, recoating and melting behavior need optimized. Post-processing parameters must also be selected based on desired properties. This section provides details on how to methodically test the effect of each setting, understand process signatures and establish control limits to hit design targets. It emphasizes the importance of documenting protocols for repeatability and continuous improvement.

C. Troubleshooting Common Issues and Errors

Being well Being well-versed in troubleshooting techniques is crucial when unforeseen issues arise during metal 3D printing projects. Some common problems addressed in this section include lack of fusion or porosity from incorrect parameters, cracking or distortion due to residual stresses, contamination from powder or equipment wear. Readers will be guided on methods to methodically diagnose the root cause such as visual inspection, X-ray, density measurement etc. Corrective actions involving rework, heat treatment or parameter adjustments are discussed. The section emphasizes maintaining process and quality records for effective issue resolution. Case studies provide real examples of troubleshooting challenges encountered during early production implementation and lessons learned. Equipping readers with these problem solving skills builds confidence in tackling new applications independently.

VIII. Conclusion

A. Recap of Key Findings and Takeaways

In this comprehensive guide, we have explored the diverse field of metal 3D printing from various perspectives - the technologies, hardware, software considerations, applications across industries, advantages as well as challenges. Readers have gained fundamental knowledge on selecting the right systems, optimizing designs and processes, ensuring quality and applying troubleshooting techniques. This section summarizes the key takeaways under each of these topics to reinforce the important concepts covered. It emphasizes how metal 3D printing is transforming manufacturing by enabling mass customization, reducing lead times and driving innovation through design freedom. The recap highlights how the technology can be harnessed successfully with the proper understanding, planning and process control.

B. Encouragement for Continued Learning and Innovation

The landscape of metal 3D printing continues to evolve at a rapid pace with ongoing research worldwide. As capabilities increase, new opportunities will emerge for leveraging these technologies. It is important that both new and experienced users remain open to continual learning to maximize the technology's potential. Users are encouraged to engage with industry forums and academic literature to stay up to date on emerging developments. Hands-on learning through community labs and training is also emphasized. With dedicated efforts to address challenges, the full scope of metal 3D printing can be unlocked. Readers are urged to approach new projects with creativity to further expand applications. Only through such innovation and knowledge sharing can we accelerate the technology's progress to transform global manufacturing.