Table of Contents:

- Introduction

- Factors to Consider When Choosing a Precision CNC Machining Supplier

- Top Precision CNC Machining Suppliers

- Case Studies

- Future Trends and Developments in Precision CNC Machining

- Conclusion

-

1. Introduction

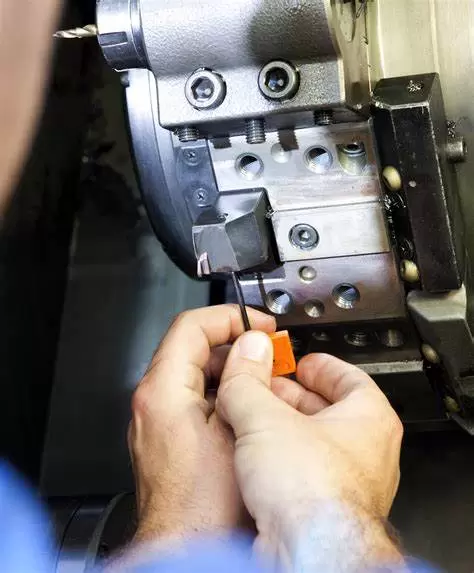

Advancements in technology have revolutionized the manufacturing industry, and one of the most impressive developments has been the rise of precision CNC machining. CNC stands for Computer Numerical Control, which basically means that advanced software and computers are used to control and automate the fabrication process. With precision CNC machining, you get superior accuracy, repeatability, and quality, all while saving on time and cost.

However, to fully harness the benefits of precision CNC machining, you need to partner with the right supplier. Choosing the wrong supplier can result in substandard products, production delays, and even lost revenue. In this guide, we’ll discuss the factors you need to consider when choosing a precision CNC machining supplier and highlight some of the top providers in the industry.

-

2. Factors to Consider When Choosing a Precision CNC Machining Supplier

A. Technical Capabilities

One of the most important factors to consider when choosing a precision CNC machining supplier is their technical capabilities. You want a supplier that has the equipment, tools, and expertise to handle your specific machining requirements. Ask about the range of materials and sizes they can work with, their tolerance levels, and their overall capacity. Make sure they have experience working with your industry and application, and that they can provide customized solutions.

B. Quality Control Processes

Precision machining requires high levels of accuracy and consistency, so quality control is critical. Look for a supplier that has a robust quality control system in place to ensure that their products meet or exceed your specifications. This should include measures like regular inspections, testing, and certifications. Ask about their procedures for dealing with nonconforming products and their track record for meeting delivery deadlines.

C. Experience and Reputation

Experience and reputation should also be taken into account when selecting a precision CNC machining supplier. Check the supplier’s credentials, certifications, and track record. Confirm their industry reputation through reviews, testimonials, and references. Look for a supplier that has a long history of providing high-quality products and services and has earned a reputation for reliability, professionalism, and expertise.

D. Pricing and Lead Times

Of course, pricing and lead times are also essential considerations when choosing a precision CNC machining supplier. You’ll want to find a supplier that can offer competitive pricing without sacrificing quality. Get detailed quotes and cost breakdowns and make sure you understand any fees or charges. Additionally, inquire about lead times, as production schedules can vary widely between suppliers.

E. Customer Service and Support

Finally, it’s crucial to evaluate a supplier’s customer service and support. You want to work with a supplier who is responsive, accessible, and easy to communicate with. Look for a supplier who has a dedicated customer service team, can provide regular updates throughout the production process, and can offer technical support and troubleshooting.

-

3. Top Precision CNC Machining Suppliers

Here are some of the top precision CNC machining suppliers in the industry today:

A. Supplier 1 – Acme Manufacturing

Acme Manufacturing is a leader in precision CNC machining, offering multi-axis milling, turning, and grinding services. They specialize in working with difficult-to-machine materials and have extensive experience in the aerospace, defense, and medical industries. Acme Manufacturing is known for their cutting-edge technology, quality control, and excellent customer service.

B. Supplier 2 – Proto Labs

Proto Labs is a global leader in quick-turn manufacturing, including CNC machining. They offer a range of materials, finishes, and secondary services, and can deliver prototypes and low-volume production runs in as little as one day. Proto Labs is known for their automated quoting system, quality control standards, and customer service.

C. Supplier 3 – Owens Industries

Owens Industries is a precision CNC machining specialist that has been in business since 1944. They offer 5-axis milling, wire EDM, and sinker EDM services, as well as engineering and design support. Owens Industries is known for their expertise in complex geometries and tight tolerances, as well as their exceptional customer service.

D. Supplier 4 – Swiss Precision Machining

Swiss Precision Machining is a family-owned precision machining shop that specializes in CNC Swiss-style turning. They have expertise in precision parts for industries like aerospace, medical devices, and defense. Swiss Precision Machining is known for their efficiency, attention to detail, and customer-centric approach.

E. Supplier 5 – Plethora

Plethora is a California-based company that provides rapid prototyping and CNC machining services. They have a quick and easy online quoting system, offer a range of materials and finishes, and can turn around projects in as little as 2-4 days. Plethora is known for their fast turnaround times, quality control, and outstanding customer service.

-

4. Case Studies

To help illustrate the importance of choosing the right precision CNC machining supplier, we’ll look at two case studies – one successful partnership and one bad experience.

A. Case Study 1: Successful Partnership with Precision CNC Machining Supplier

A leading aerospace company was experiencing production delays and quality issues with their previous precision machining supplier. They decided to switch to Acme Manufacturing, one of the top suppliers mentioned earlier in this guide. Acme was able to quickly assess the situation and identify several inefficiencies in the production process. They worked closely with the aerospace company to develop customized solutions that improved quality, cut cycle times, and reduced costs. Thanks to the successful partnership, the aerospace company was able to improve their bottom line and meet their customer demand.

B. Case Study 2: Lessons Learned from Choosing the Wrong Supplier

A medical device manufacturer was seeking a new supplier for their precision CNC machining needs. They chose a supplier that offered low pricing, but unfortunately, they soon discovered that the supplier was using inferior materials and cutting corners on quality control. The manufacturer ultimately had to scrap an entire production run, which cost them time, money, and reputational damage. They realized too late that they should have prioritized experience, reputation, and quality control over cost.

-

5. Future Trends and Developments in Precision CNC Machining

Precision CNC machining is a rapidly evolving field, and there are several trends and developments to keep an eye on. Some key areas of focus include:

A. Advances in Technology

The development of new materials, coatings, and cutting tools is enabling even more precise and efficient machining. Additionally, automation and artificial intelligence are being integrated into precision machining processes, which can improve productivity and reduce costs.

B. Sustainability Initiatives

As industries become more conscious of their environmental impact, precision CNC machining suppliers are implementing sustainability initiatives. This includes things like reducing waste, utilizing eco-friendly materials, and implementing energy-efficient practices.

C. Emerging Markets

As the global economy expands, there is increased demand for precision machining in emerging markets like China, India, and Brazil. It’s expected that there will be a rise in domestic suppliers in these regions, which could provide more options for companies looking for precision machining partners.

If you need about CNC Machining Services,You can click on the V1 Prototype website to find it.

-

6. Conclusion

In conclusion, selecting the right precision CNC machining supplier is crucial for success in manufacturing. Technical capabilities, quality control processes, experience, reputation, pricing and lead times, and customer service and support are all critical factors to evaluate. By taking the time to research and select the right supplier, companies can save time and money, improve quality, and enhance their overall production process. With the continued development of technology and sustainability initiatives, precision CNC machining will remain a key component of manufacturing in the future.