Introduction

Bioprinting, a cutting-edge application of 3D printing technology, has revolutionized the fields of regenerative medicine, tissue engineering, and pharmaceutical research. The ability to fabricate three-dimensional living structures and functional tissues using bioinks and living cells holds immense promise for advancing medical treatments and drug development. V1Prototype, a leading innovator in the 3D printing industry, has taken a bold step in advancing bioprinting with the development of a new 3D printing device. In this blog post, we will explore V1Prototype's groundbreaking contributions to bioprinting, the capabilities of their new 3D printing device, and the potential impact on the future of healthcare and scientific research.

Pioneering Bioprinting Advancements

V1Prototype has been at the forefront of 3D printing technology, consistently pushing the boundaries of what is possible in additive manufacturing. Recognizing the tremendous potential of bioprinting, the company invested in research and development to create a specialized 3D printing device dedicated to bioprinting applications. This device marks a significant milestone in the journey towards engineering functional tissues and organs for medical purposes.

The Capabilities of V1Prototype's New 3D Printing Device

V1Prototype's new bioprinting device boasts several cutting-edge capabilities that set it apart from traditional 3D printers:

1. Multi-Material Printing

The bioprinting device is equipped with multi-material capabilities, enabling the simultaneous deposition of various bioinks and cell types. This feature allows the creation of complex and heterogeneous tissue structures, mimicking the intricate organization of natural tissues.

2. High Precision and Resolution

With micron-level precision and resolution, V1Prototype's bioprinting device ensures accurate placement of cells and biomaterials, crucial for creating functional tissues with cellular viability and desired mechanical properties.

3. Real-Time Monitoring and Feedback

The device is equipped with sophisticated imaging and sensing technologies that provide real-time monitoring and feedback during the bioprinting process. This enables researchers to adjust printing parameters and optimize tissue fabrication in real-time, improving reproducibility and efficiency.

4. Advanced Bioinks

V1Prototype has developed a range of advanced bioinks, each tailored to specific tissue types and applications. These bioinks support cell viability, adhesion, and differentiation, enhancing the functionality and maturation of the printed tissues.

5. Integration with CAD and Imaging Software

The bioprinting device seamlessly integrates with computer-aided design (CAD) software and medical imaging tools, allowing for precise and patient-specific tissue engineering. This integration streamlines the translation of medical data into bioprinted constructs.

Advancing Healthcare and Scientific Research

V1Prototype's commitment to advancing bioprinting technology holds tremendous potential for various healthcare and scientific applications:

1. Organ Transplantation and Regenerative Medicine

The ability to bioprint functional organs and tissues opens new avenues for organ transplantation, potentially alleviating organ shortages and reducing the risk of transplant rejection.

2. Drug Development and Personalized Medicine

Bioprinted tissue models can serve as more accurate and predictive platforms for drug testing, enabling safer and more effective drug development. Additionally, the personalized nature of bioprinted tissues allows for patient-specific drug testing and treatment strategies.

3. Disease Modeling and Research

Bioprinted tissues provide researchers with physiologically relevant disease models, facilitating the study of complex diseases and accelerating biomedical research.

4. Custom Implants and Prosthetics

V1Prototype's bioprinting device can aid in the fabrication of custom implants and prosthetics, tailored to individual patients' needs and anatomies.

Conclusion

V1Prototype's new 3D printing device represents a significant leap forward in the field of bioprinting, empowering researchers and healthcare professionals with advanced tools to engineer functional tissues and organs. The multi-material capabilities, high precision, and integration with imaging software make this bioprinting device a powerful tool for driving innovations in regenerative medicine, drug development, and disease research. As V1Prototype continues to pioneer bioprinting advancements, the future of healthcare and scientific research looks brighter than ever, promising transformative breakthroughs in medical treatments and personalized therapies.

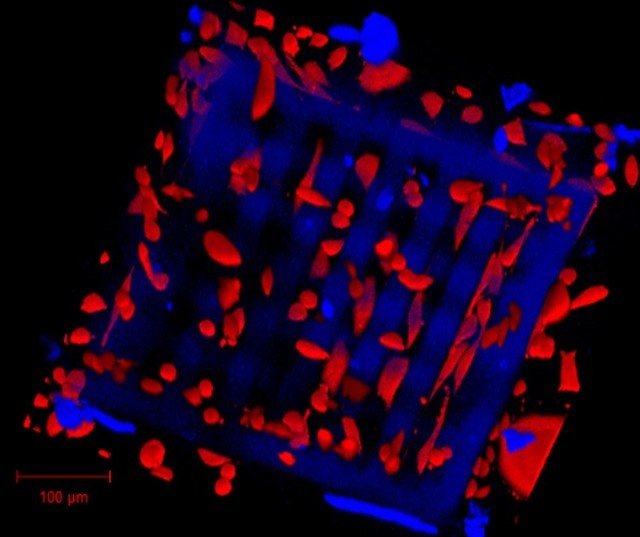

To date, flat 2D cell scaffolds have been used extensively in biomedical research, however 2D models do not accurately represent cellular interactions in biological systems, and the testing and development of relevant drugs often results in errors as a result. To avoid such errors, 3D printer manufacturer UpNano has launched its new NanoOne Bio 3D bioprinting system, which is capable of printing 3D tissue structures of living cells from the mesoscale to the nanoscale.

The printing of high-precision 3D scaffolds with embedded live cells has so far been hampered by limitations in materials and 3D bioprinting systems. The company has also collaborated with biomaterials developer Xpect INX (a division of Ghent University) to create a hydrogel-based bioink for a completely new 3D printing system. the joint development of NanoOne Bio and X Hydrobio INX U200 resin is expected to change this situation as described above.

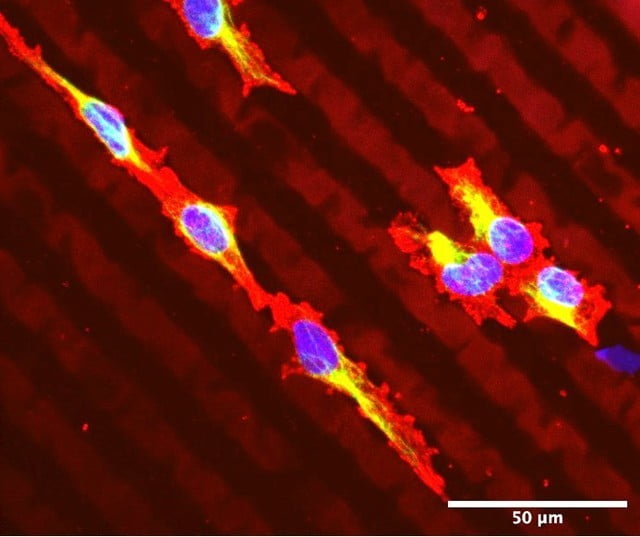

X Hydrobio INX U200 is compatible with osteoblasts

Xpect's new bioink is a water-soluble hydrogel that enables users to integrate live 2D cell cultures directly from their culture dishes. Once embedded in the bioink, the cells can be fed directly into the NanoOne Bio where they are printed in a complex 3D scaffold. Thanks to the system's use of this high-powered laser, structures are printed both precisely and quickly, meaning users will be able to create centimetre-scale structures with ease.

Jasper Van Hoorick, Xpect INX project leader, explains, "The gelatin-based X Hydrobio INX U200 has been developed specifically for the encapsulation of multiple cell types and can therefore generate complex 3D microscopic tissues." "The hydrogel mimics the natural cellular environment and is biodegradable, thus allowing cells to gradually replace this material with newly formed tissue."

X Hydrobio INX U200 fused to corneal endothelial cells

With the launch of NanoOne Bio, UpNano expects customers in academia and industry. It is now possible to 3D print cellular structures that resemble real biological tissue, thus enabling natural interactions between cells and environmental stimuli. Pharmaceutical companies and research institutions alike will be empowered to design cellular models that more closely match actual human conditions, thus making drug development and other biomedical research safer and more reliable.