As a leading CNC machining provider in China, we specialize in producing precision parts for a wide variety of industries. Utilizing state-of-the-art technology and experienced staff, we guarantee the highest-quality products at competitive prices. Contact us today for all your CNC machining needs.

Table of Contents

I. Introduction to Precision CNC Machining in China

A. What is CNC Machining?

B. Importance of Precision CNC Machining in Manufacturing

C. Why Choose a Machining Provider in China?

II. Challenges and Solutions for CNC Machining in China

A. Language and Cultural Barriers

B. Quality Control and Standards

C. Supply Chain Management

D. Innovative Solutions for CNC Machining in China

III. Benefits of Choosing a CNC Machining Provider in China

A. Cost-Effective Production

B. State-of-the-Art Equipment and Technology

C. Skilled and Trained Staff

D. Customized Solutions

E. Fast Turnaround Times

IV. Quality Control and Certifications in CNC Machining in China

A. Quality Control Measures in CNC Machining

B. Certifications and Standards for CNC Machining Providers in China

C. Benefits of Working with a Quality CNC Machining Provider in China

V. Choosing the Right CNC Machining Provider in China

A. Assessing Your CNC Machining Requirements

B. Researching Potential Providers in China

C. Requesting Quotes and Proposals

D. Reviewing Quality and Performance Metrics

E. Selecting the Best-Fit CNC Machining Provider

VI. Conclusion - The Role of Precision CNC Machining Providers in China

A. Benefits and Opportunities of Working with CNC Machining Providers in China

B. Best Practices for a Successful Business Partnership.

I. Introduction to Precision CNC Machining in China

A. What is CNC Machining?

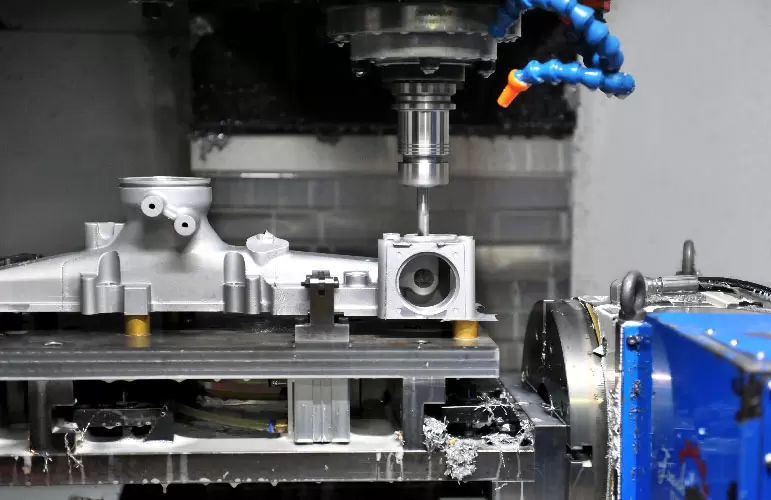

CNC machining is a manufacturing process that involves using computer-controlled machines to create precise components or parts. The machines remove material from a raw workpiece to form a final product that meets customer specifications. In China, CNC machining has become a popular method for producing high-quality components for a range of industries, including automotive, aerospace, medical, and electronics.

B. Importance of Precision CNC Machining in Manufacturing

In today’s highly competitive manufacturing landscape, precision machining is critical to ensuring high-quality products that meet customer demands. With the use of advanced technology and skilled labor, CNC machining in China is able to produce complex parts and components with high accuracy and consistency.

C. Why Choose a Machining Provider in China?

There are several compelling reasons to choose a CNC machining provider in China. China is a global manufacturing powerhouse, with an abundance of raw materials, advanced technology, and skilled labor. In addition, China’s low labor and production costs make it a cost-effective option for companies looking to outsource their manufacturing needs.

II. Challenges and Solutions for CNC Machining in China

A. Language and Cultural Barriers

One of the biggest challenges of outsourcing CNC machining to China is the language and cultural barriers. Communication breakdowns can cause significant delays, errors, and misunderstandings. However, by working with a CNC machining provider that has multilingual staff or dedicated translators, these challenges can be overcome.

B. Quality Control and Standards

Maintaining quality control and standards is crucial in the CNC machining industry. However, some manufacturing facilities in China may not adhere to the same level of quality control as those in other countries. By working with a reputable CNC machining provider in China that has strict quality control measures in place, manufacturers can be assured of the quality of their components.

C. Supply Chain Management

Supply chain management can be another challenge in outsourcing CNC machining to China. With logistical challenges such as shipping, customs, and import/export regulations, it’s essential to work with a CNC machining provider in China that understands the ins and outs of international trade.

D. Innovative Solutions for CNC Machining in China

Despite the challenges of outsourcing CNC machining to China, there are also opportunities for innovative solutions. With China’s vast manufacturing ecosystem and advanced technology, CNC machinists in China can provide creative solutions for complex production challenges.

III. Benefits of Choosing a CNC Machining Provider in China

A. Cost-Effective Production

One of the most significant advantages of outsourcing CNC machining to China is cost-effectiveness. Due to the lower cost of labor and production in China, companies can save money on CNC machining projects without compromising quality.

B. State-of-the-Art Equipment and Technology

CNC machining providers in China often use the latest, state-of-the-art equipment and technology. With advanced machinery, these providers can produce high-quality products with precision and efficiency.

C. Skilled and Trained Staff

Many CNC machining providers in China employ skilled and trained staff who are experts in the manufacturing process. These machinists have years of experience and can produce complex parts with high accuracy and consistency.

D. Customized Solutions

CNC machining providers in China can offer customized solutions that meet specific customer needs. By working closely with customers to understand their requirements, these providers can produce components that meet exact specifications.

E. Fast Turnaround Times

CNC machining providers in China can often provide fast turnaround times for projects due to their efficient manufacturing processes and advanced machinery.

IV. Quality Control and Certifications in CNC Machining in China

A. Quality Control Measures in CNC Machining

Maintaining quality control measures is critical in the CNC machining industry, as parts and components must meet strict specification requirements for performance and reliability. In China, reputable CNC machining providers will have strict quality control measures in place to ensure that all components produced meet the required standards. Measures such as frequent inspections, quality testing, and documentation are used to provide reliable products that meet customer specifications.

B. Certifications and Standards for CNC Machining Providers in China

When selecting a CNC machining provider in China, it’s essential to consider certifications and standards. Providers that adhere to international standards such as ISO 9001 demonstrate a commitment to quality control and provide customers with greater confidence in their capabilities. Other industry-specific certifications, such as AS9100 for aerospace, may also be relevant depending on the application.

C. Benefits of Working with a Quality CNC Machining Provider in China

Working with a quality CNC machining provider in China can provide several benefits, such as high-quality components that meet customer specifications, cost savings, and reduced lead times. Additionally, with a focus on quality control, customers can have confidence in the reliability and performance of the components produced.

V. Choosing the Right CNC Machining Provider in China

A. Assessing Your CNC Machining Requirements

Before selecting a CNC machining provider in China, it’s essential to assess your requirements and specifications. This can include factors such as the complexity of the project, required tolerances, and materials used. Understanding your needs can help in the decision-making process and ensure that you partner with a provider that can meet your requirements.

B. Researching Potential Providers in China

Researching potential CNC machining providers in China can help you identify reputable providers with a track record of producing high-quality components. This can include reading reviews from previous customers, evaluating certifications and quality control measures, and requesting quotes.

C. Requesting Quotes and Proposals

Requesting quotes and proposals from multiple CNC machining providers in China can help you compare pricing, lead times, and quality control measures. By evaluating multiple providers, you can select the provider that can meet your specifications at the best value.

D. Reviewing Quality and Performance Metrics

Reviewing quality and performance metrics of CNC machining providers in China can provide insight into their capabilities and track record. Metrics such as tolerances achieved, on-time delivery, and customer satisfaction can indicate the provider’s ability to meet your needs.

E. Selecting the Best-Fit CNC Machining Provider

By using the above criteria, you can select the best-fit CNC machining provider in China that meets your needs and can provide high-quality components at a competitive price. Partnering with the right provider can help you improve your manufacturing operations and gain a competitive advantage.

VI. Conclusion - The Role of Precision CNC Machining Providers in China

Precision CNC machining providers in China play a vital role in meeting the manufacturing needs of a range of industries. Whether it’s outsourcing production or finding innovative solutions to complex challenges, CNC machining providers in China can provide high-quality components that meet exact specifications. By understanding the key challenges and benefits of working with CNC machining providers in China, businesses can make informed decisions and succeed in their manufacturing operations.