Table of Contents:

- Introduction to Rapid Prototyping

- Rapid Prototyping Technologies in the UK

- Applications of Rapid Prototyping in the UK

- Advantages and Limitations of Rapid Prototyping

- Future of Rapid Prototyping in the UK

- Conclusion

-

1.Introduction to Rapid Prototyping

Rapid prototyping is a method used to quickly produce a physical model or prototype of a product, using computer-aided design (CAD) data. This technique has revolutionized the product design and development process, allowing designers and engineers to test their ideas quickly and make adjustments before moving on to the final product. In this article, we will provide an overview of rapid prototyping in the United Kingdom, including the technologies used, the applications, the advantages and limitations, and the future of rapid prototyping in the UK.

-

2.Rapid Prototyping Technologies in the UK

There are several rapid prototyping technologies used in the UK, including stereolithography, fused deposition modeling, selective laser sintering, multi-jet fusion, and digital light processing.

Stereolithography is a process that uses a laser to cure a liquid resin, layer by layer, to create a solid object. This technology is used to create high-quality, detailed prototypes and is widely used in the automotive and aerospace industries.

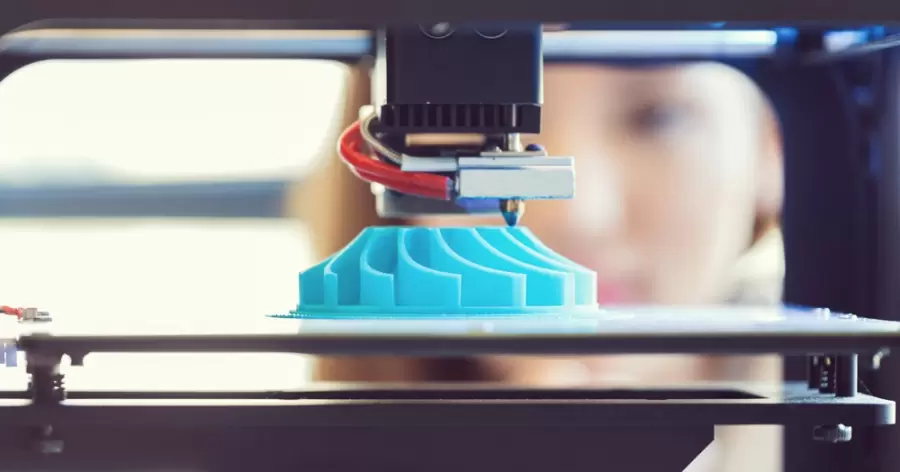

Fused deposition modeling uses a plastic filament that is melted and extruded through a nozzle to create a three-dimensional object. This technology is widely used in the consumer product industry, as it is relatively inexpensive and can produce prototypes quickly.

Selective laser sintering uses a laser to fuse powdered materials together, layer by layer, to create a solid object. This technology is used to create complex geometries and is widely used in the medical and aerospace industries.

Multi-jet fusion is a technology that uses a powder bed and an inkjet printhead to fuse powder particles together. This technology is used to create high-quality, detailed prototypes and is widely used in the automotive and aerospace industries.

Digital light processing uses a projector to create a two-dimensional image on a resin surface, which is then cured by a UV light to create a three-dimensional object. This technology is used to create high-quality, detailed prototypes and is widely used in the medical and dental industries.

-

3.Applications of Rapid Prototyping in the UK

Rapid prototyping is used in a wide range of industries in the UK, including the automotive, aerospace, medical, consumer product, architecture, and construction industries.

In the automotive industry, rapid prototyping is used to create prototypes of new vehicle designs, as well as for creating replacement parts and tooling.

In the aerospace industry, rapid prototyping is used to create prototypes of new aircraft designs, as well as for creating parts for existing aircraft.

In the medical industry, rapid prototyping is used to create models of human organs and body parts, as well as for creating prosthetics and medical devices.

In the consumer product industry, rapid prototyping is used to create prototypes of new products, as well as for creating replacement parts and tooling.

In the architecture and construction industries, rapid prototyping is used to create models of buildings and structures, as well as for creating custom parts and components.

-

4.Advantages and Limitations of Rapid Prototyping

Rapid prototyping offers several advantages, including the ability to quickly produce prototypes, the ability to test and refine designs before moving on to production, and the ability to create complex geometries that would be difficult or impossible to produce with traditional manufacturing methods.

However, rapid prototyping also has some limitations, including the relatively high cost of some of the technologies, the limited range of materials that can be used, and the limitations of the size of the objects that can be produced.

-

5.Future of Rapid Prototyping in the UK

The future of rapid prototyping in the UK looks bright, with new technologies and materials being developed that will allow for even more complex and high-quality prototypes to be produced. Additionally, as the cost of rapid prototyping technologies continues to decrease, it is likely that more companies will be able to take advantage of this technology to improve their product development process.

In addition to new technologies and materials, the future of rapid prototyping in the UK will also be shaped by advances in other areas, such as artificial intelligence and machine learning. These technologies will allow for faster and more accurate design optimization and will help to further streamline the prototyping process.

If you need about Rapid Prototyping Services,You can click on the V1 Prototype website to find it.

-

6.Conclusion

In conclusion, rapid prototyping is a valuable tool for product designers and engineers in the UK, allowing them to quickly produce and test physical prototypes of their designs. With a range of technologies available and applications in a variety of industries, rapid prototyping has become an essential part of the product development process. While there are some limitations to the technology, the future of rapid prototyping in the UK looks promising, with new materials and technologies on the horizon that will further improve the speed and quality of the prototyping process. As such, it is likely that rapid prototyping will continue to be an important part of the product design and development landscape in the UK and beyond.