Table of Contents:

- Introduction

- Types of Plastic Texture

- Techniques for Creating Plastic Texture

- Applications of Plastic Texture

- Considerations When Choosing Plastic Texture

- Conclusion

-

1.Introduction

Plastic texture refers to the surface of a plastic material that is intentionally manipulated to have a particular texture or pattern. This is achieved through various techniques such as injection molding, thermoforming, rotomolding, extrusion, and others. The texture can range from a subtle design to an intricate, highly detailed pattern.

Importance of Plastic Texture in Different Industries:The texture of plastic plays a vital role in many industries, including automotive, consumer goods, packaging, medical, and many others. It not only enhances the aesthetic appeal of the product, but also adds to its functional capabilities. For example, a textured plastic surface can improve grip and prevent accidental slips, while also adding visual interest to the product. In the packaging industry, the texture of plastic can be used to provide tamper-proof seals or to help products stand out on the shelf. Additionally, in the medical industry, texture can be used to make devices easier to grip and prevent them from slipping out of the hands of medical professionals. The importance of plastic texture in various industries cannot be overstated, and as products continue to evolve, so will the demand for improved, customizable textures.

-

2. Types of Plastic Texture

There are several different types of plastic textures used in various industries. Here are some of the most commonly used ones:

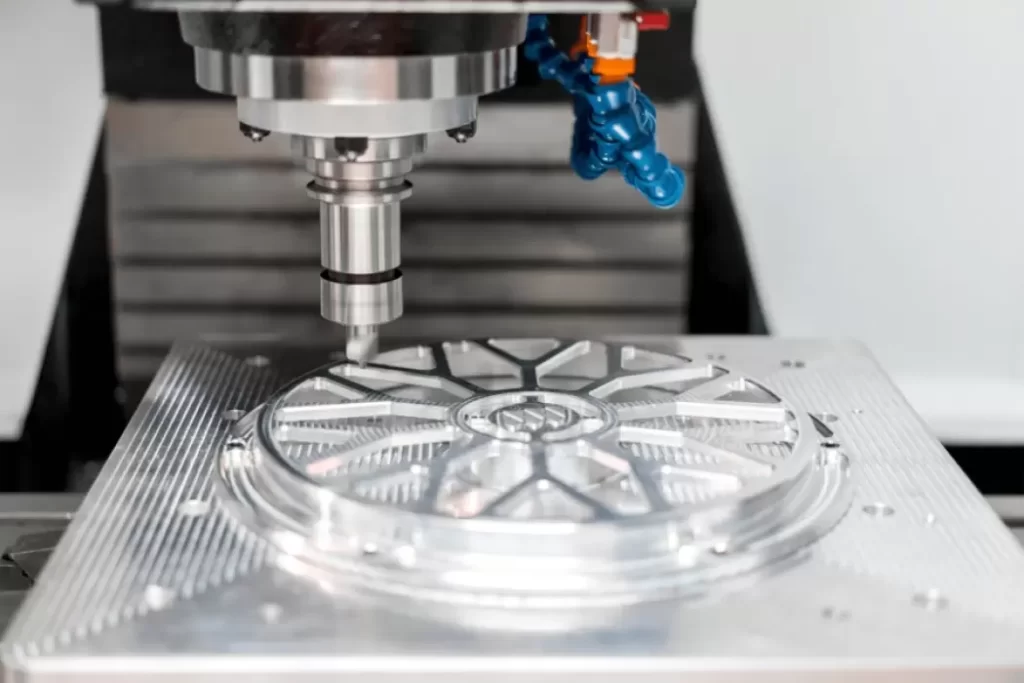

- Injection-Molded Texture: This is a process where the plastic material is melted and injected into a mold to give it its shape and texture. The material is then cooled and removed from the mold. Injection molding can create intricate patterns and designs, which makes it popular in the automotive and consumer goods industries.

- Extruded Texture: In this process, the plastic is melted and extruded into the desired shape and textured by passing through a die. This process is commonly used in the production of pipes, tubes, and other products that require a consistent texture along the length of the product.

- Rotational Molded Texture: This process involves filling a mold with plastic and rotating it on several axes while heating it. The plastic then gradually adheres to the mold and takes on its texture. This method is often used in making large, hollow objects such as containers, kayaks, and playground equipment.

- Thermoforming Texture: In this process, a flat sheet of plastic is heated to a pliable state and then molded into shape and texture using pressure and a vacuum. Thermoforming is commonly used in the packaging and automotive industries.

- Blow-Molded Texture: This process involves heating a plastic tube until it is soft and then blowing it into a mold to create the desired shape and texture. This process is often used in the production of bottles and other hollow shapes.

Each of these methods has its unique advantages and disadvantages, and the choice of which one to use depends on the desired outcome and the application of the product.

-

3. Techniques for Creating Plastic Texture

In addition to the methods mentioned above, there are several techniques for creating plastic texture:

- Chemical Etching: This process involves applying a chemical solution to the surface of the plastic to dissolve certain areas and create a specific pattern or design. This method is commonly used in the aerospace and automotive industries.

- Sandblasting: In this process, small particles of sand or other abrasive material are blasted onto the surface of the plastic to create a textured effect. This method is often used for decorative purposes, such as in the production of signs and displays.

- Laser Engraving: This technique uses a laser beam to etch a pattern or design onto the surface of the plastic. This method is highly precise and can create intricate designs. Laser engraving is commonly used in the production of electronic devices and components.

- Embossing: This process involves pressing a pattern or design onto the surface of the plastic to create a raised effect. Embossing is a popular method for adding texture to packaging materials.

- Roll Texturing: This technique involves passing the plastic sheet or material through a series of specially designed rolls with raised patterns or designs. This method is commonly used in the production of films and laminates.

These techniques offer a range of options for manipulating plastic texture to achieve the desired effect. The choice of which technique to use depends on the properties of the plastic material, the desired outcome, and the practical considerations of the production process.

-

4.Applications of Plastic Texture

Plastic texture has countless applications across various industries. Here are some of the most common applications:

- Automotive Industry: Plastic texture plays a critical role in the design and aesthetics of automotive components. The use of injection molding and other texturing techniques make it possible to create intricate designs for car dashboards, buttons, and other interior features. Additionally, textured plastic is popular for creating non-slip surfaces on car pedals, steering wheels, and other components.

- Consumer Goods Industry: Many consumer goods, such as electronics, appliances, and toys, use textured plastic to improve the appearance and functionality of the product. For example, textured plastic material can be used to create a non-slip grip on product handles or as a decorative element in smartphone cases.

- Packaging Industry: Textured plastic is commonly used in the packaging industry to create tamper-evident seals or to add texture to labels for better visual appeal. Textured packaging can help products stand out on the shelves and give consumers a better tactile experience when handling products.

- Medical Industry: The medical industry uses textured plastics for a wide range of applications, including surgical devices, implants, and laboratory equipment. Textured plastic surfaces can improve grip strength, make it easier to handle delicate instruments, and help prevent slips and other accidents.

Overall, the applications of plastic texture in different industries continue to evolve and expand as new techniques and methods are developed, opening up new possibilities for creating unique and innovative products.

-

5.Considerations When Choosing Plastic Texture

When choosing the appropriate plastic texture for a particular product, several factors must be considered. Here are some of the most important considerations:

- Aesthetic Preferences: The desired look and feel of the product should be taken into account when choosing the texture of the plastic material. Aesthetic considerations may include the color, pattern, and texture of the product.

- Functionality Needs: The intended use of the product should also be considered when choosing the texture of the plastic material. For example, if the product needs to be non-slip, a coarse texture may be required. If the product needs to be easily cleaned, a smooth, non-porous texture may be best.

- Material Requirements: The properties of the plastic material itself must be taken into account. Different types of plastics have varying levels of transparency, flexibility, chemical resistance, and other properties that may affect the choice of texture.

Overall, the choice of plastic texture should be based on a combination of aesthetic preferences, functionality needs, and material requirements. By carefully considering these factors, it is possible to achieve the desired outcome and create a product that meets the needs of the intended user.

-

6.Conclusion

In conclusion, plastic texture is an essential element in the design and production of various products across different industries. The choice of texture should be based on a combination of aesthetic preferences, functionality needs, and material requirements to achieve the desired outcome.

Summary of key points:

- Plastic texture refers to the surface of a plastic material that is intentionally manipulated to have a particular texture or pattern.

- Different types of plastic texture include injection-molded texture, extruded texture, rotational molded texture, thermoforming texture, and blow-molded texture.

- Techniques for creating plastic texture include chemical etching, sandblasting, laser engraving, embossing, and roll texturing.

- Plastic texture has countless applications across various industries, including automotive, packaging, consumer goods, and medical.

- Considerations when choosing plastic texture should include aesthetic preferences, functionality needs, and material requirements.

Future trends in plastic texture will likely continue to focus on developing more intricate, customized textures that offer both aesthetic appeal and functional improvements. Additionally, advances in 3D printing and other technologies are expanding the possibilities for creating unique patterns and designs that were previously impossible. As the demand for high-quality, customized products continues to grow, plastic texture will remain a critical element in the design and production of innovative products.