Stereolithography (SLA) is a popular technique used in rapid prototyping to produce high-quality and detailed 3D models. In this article, we will explore the benefits of stereolithography technology for rapid prototyping. You will learn about the history of stereolithography, how it works, the materials used, and the potential applications of this exciting technology. We will also touch on the advantages of using stereolithography in rapid prototyping of various products.

I. Introduction

Stereolithography is an additive manufacturing technology that provides high-quality and highly detailed 3D models. It is widely used in rapid prototyping of various products across many industries. Stereolithography allows designers and engineers to visualize, test, and validate product designs in the early stages of development. In this article, we take an in-depth look at the benefits of stereolithography technology for rapid prototyping, the various materials that can be used, and some possible applications in key industries like medical, aerospace, automotive, and consumer goods.

II. How Stereolithography Works

Stereolithography is a 3D printing technique that uses ultraviolet (UV) laser-induced photopolymerization to solidify liquid photopolymer resin layer by layer. The stereolithography machine contains a reservoir filled with liquid photopolymer resin. A digital 3D model is first created using computer-aided design (CAD) software and then converted into cross-sectional slices. The stereolithography machine reads these slices and uses a UV laser to trace each slice pattern on the surface of the liquid resin, causing photopolymerization and solidification. There are three main types of stereolithography processes: top-down SLA, bottom-up SLA, and digital light processing (DLP). Each method solidifies the photopolymer resin in a different way to build the 3D model layer by layer.

III. Materials Used for Stereolithography

Common photopolymer resins used in stereolithography include epoxy, acrylate, and composite resins. Epoxy resins provide high strength and temperature resistance but have a lower resolution, while acrylate resins offer very high resolution and detail but are more brittle. Composite resins containing ceramics, metals, or other fillers can be used to produce functional prototypes with properties similar to the actual production materials. The material chosen depends on the required mechanical properties, surface finish, accuracy, and application of the final prototype. Advanced materials like metal composites and nanocomposites are also being explored to further expand the capabilities of stereolithography.

IV. Advantages of Stereolithography for Rapid Prototyping

Stereolithography provides several key advantages for rapid prototyping. It can produce prototypes with resolutions of up to 0.1 mm layer thickness, allowing for highly intricate geometric details and surface features to be replicated. The process is also very fast, with build times ranging from a few hours to over 24 hours depending on the size and complexity of the design. This helps reduce the overall product development cycle time. Stereolithography prototypes also have mechanical properties similar to injection molded plastic parts. The materials used can be machined, painted, and post-processed as needed. Overall, stereolithography delivers high-fidelity prototypes for functional testing and design validation early in the development process.

V. Applications of Stereolithography Rapid Prototyping

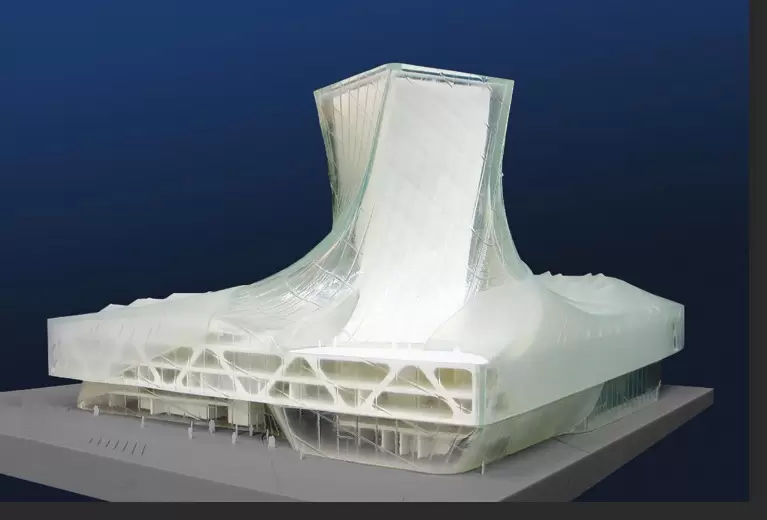

In the medical industry, stereolithography is used to produce anatomical models for surgery planning, custom implants and prosthetics, and dental models. In aerospace applications, it is used to build prototypes of aircraft engine components, aircraft cabin interiors, and spacecraft parts for testing in simulated environments. Automotive manufacturers utilize SLA for prototyping vehicle interior parts, exterior body panels, and functional prototypes. Consumer goods companies employ it to prototype electronics, home appliances, toys, and various other consumer products. Other emerging applications of stereolithography rapid prototyping include in the fields of architecture, jewelry, education, and more.

VI. Considerations in Using Stereolithography for Rapid Prototyping

While stereolithography delivers high-fidelity prototypes, some limitations must be considered. The size of prototypes is restricted by the build volume of the SLA machine, which ranges from 8-36 inches in most desktop and industrial systems. The material properties also may not exactly match the final production material in some cases. Post-processing like support structure removal and finishing is also required. The equipment and consumables like resins also have a higher initial cost compared to some other 3D printing technologies. However, the precision, speed and quality benefits often outweigh these limitations for applications requiring detailed form and fit evaluation of prototypes.

VII. Conclusion

In conclusion, stereolithography has revolutionized the rapid prototyping industry by enabling the fast, precise fabrication of detailed, functional prototypes using a wide variety of materials. The technology continues to develop with larger build volumes and new materials. Stereolithography remains one of the most versatile and accurate 3D printing processes for applications from product design validation to surgical modeling that demand high-fidelity replication of the final design. Its widespread use is expected to grow further with the continued expansion of additive manufacturing.