Table of Contents:

- Introduction

- Techniques and Technologies Used in CNC Milling

- Applications of CNC Milling

- Advancements in CNC Milling

- Common Materials and Finishing Techniques

- Challenges and Limitations of CNC Milling

- Conclusion

-

1 Introduction:

CNC milling, or computer numerical control milling, is a versatile and precise manufacturing process that uses automated machines to remove material from a workpiece to create a desired shape or part. The use of CNC milling has become increasingly popular in various industries, including automotive, aerospace, medical, and electronics. This article provides an overview of the CNC milling process, including the techniques, applications, advancements, materials, and challenges associated with this method.

-

2 Techniques and Technologies Used in CNC Milling:

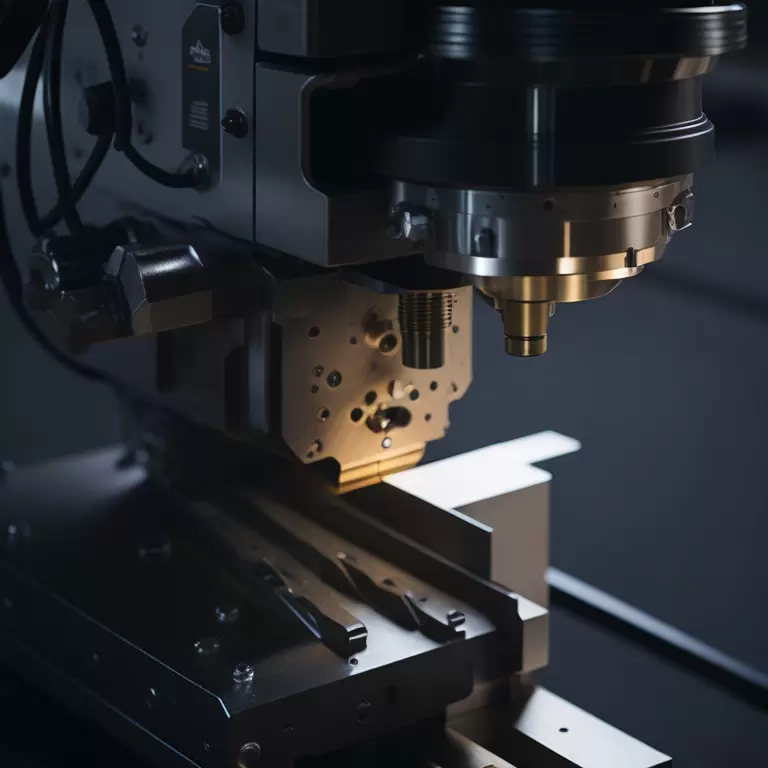

CNC milling machines can vary in size, complexity, and function. There are three primary types of CNC milling machines: vertical milling machines, horizontal milling machines, and gantry milling machines. Each machine has its own advantages and limitations, and the selection depends on the specific application requirements.

Tooling and workholding devices play a crucial role in the CNC milling process. Various types of cutting tools are used to remove material from the workpiece, including end mills, drills, reamers, and taps. Workholding devices, such as vises, clamps, and fixtures, are used to secure the workpiece to the machine table during the milling process.

CAD/CAM software is an essential component of CNC milling. Computer-aided design (CAD) software is used to create a digital model of the part or component, while computer-aided manufacturing (CAM) software is used to generate the tool paths and G-code instructions required for the CNC machine to produce the desired part.

-

3 Applications of CNC Milling:

CNC milling is used in a wide range of applications, from industrial manufacturing to prototyping and product development. In the automotive industry, CNC milling is used to produce engine components, suspension parts, and body panels. In the aerospace industry, CNC milling is used to produce turbine blades, wing components, and landing gear. In the medical industry, CNC milling is used to produce dental implants, surgical tools, and prosthetics. In the electronics industry, CNC milling is used to produce circuit boards, heat sinks, and enclosures.

CNC milling is also used in art and sculpture. Artists and designers can use CNC milling to create intricate and detailed sculptures, jewelry, and furniture. The use of CNC milling in art has opened up new possibilities for artists to create complex designs that would be difficult or impossible to produce by hand.

-

4 Advancements in CNC Milling:

Advancements in CNC milling technology have led to increased speed, accuracy, and efficiency. High-speed machining is a technique that uses high-speed spindles and specialized cutting tools to remove material at a faster rate than traditional milling. 5-axis machining allows for greater flexibility and precision by enabling the machine to move the workpiece in five directions. Hybrid CNC machines combine the advantages of CNC milling with other technologies, such as 3D printing, to create complex parts and components.

Industry 4.0 and the Internet of Things (IoT) have also had an impact on CNC milling. Smart manufacturing systems that incorporate sensors, data analytics, and artificial intelligence (AI) can optimize the milling process by identifying and correcting errors in real-time, reducing downtime, and improving overall efficiency.

-

5 Common Materials and Finishing Techniques:

CNC milling can be used to work with a variety of materials, including metals, plastics, and composites. Different materials require different cutting tools, speeds, and feeds to achieve the desired results. Surface finishing and coating techniques, such as sandblasting, anodizing, and powder coating, can be used to improve the appearance and durability of the finished product.

If you need about CNC Milling Services,You can click on the V1 Prototype website to find it.

-

6 Challenges and Limitations of CNC Milling:

Despite its many advantages, CNC milling has some limitations and challenges. The cost of CNC milling machines and tooling can be prohibitively expensive, especially for small businesses and startups. Maintenance and programming requirements can also be time-consuming and complex, requiring skilled operators and programmers. Material constraints can also limit the types of parts and components that can be produced using CNC milling. Some materials, such as ceramics and certain types of plastics, can be difficult to machine due to their hardness and brittleness.

-

7 Conclusion:

CNC milling is a versatile and precise manufacturing process that has revolutionized the way we produce parts and components. Advances in technology have led to faster, more efficient, and more precise milling machines, allowing for greater flexibility and creativity in design. CNC milling is used in a wide range of industries, from automotive and aerospace to medical and electronics, as well as in art and sculpture. While there are some challenges and limitations associated with CNC milling, the benefits far outweigh the drawbacks. As technology continues to evolve, it is likely that CNC milling will become even more advanced and widespread in the years to come.