This article provides insights into Functionally Graded Materials 3D Printing and their potential applications in different industries. Learn how FGMs can revolutionize material science and allow for the creation of complex parts with varying properties.

Table of Contents:

I. Introduction

II. Functionally Graded Materials: An Overview

III. FGMs 3D Printing Techniques

IV. Applications of FGMs 3D Printing

V. Advantages and Disadvantages of FGMs 3D Printing

VI. Future of FGMs 3D Printing

VII. Conclusion

I. Introduction

The development of 3D printing technology has provided new avenues for innovation in the field of material science. Functionally Graded Materials (FGMs) 3D printing is one such innovation that has the potential to revolutionize the way we design and manufacture complex parts. This article provides insights into FGMs 3D printing, its techniques, applications, and future scope.

II. Functionally Graded Materials: An Overview

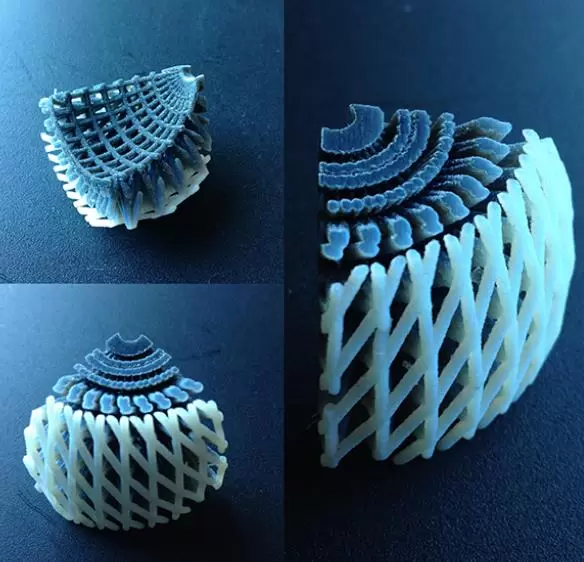

Functionally Graded Materials (FGMs) are materials that have a varying composition, microstructure, and properties over their volume. These materials can be designed to have specific functions in different regions of the material. FGMs are typically used in applications such as thermal barriers, wear-resistant coatings, and biomedical implants.

III. FGMs 3D Printing Techniques

FGMs 3D printing involves the use of multiple materials with different properties to create complex parts with varying material properties. Some of the common FGMs 3D printing techniques include:

- Extrusion-based: This technique involves extruding multiple materials from separate nozzles, which are then merged onto a single point.

- Powder-based: In this technique, multiple powders are selectively deposited and fused together using a laser or electron beam.

- Inkjet-based: This technique involves using multiple print heads to selectively deposit different materials onto a substrate.

IV. Applications of FGMs 3D Printing

FGMs 3D printing has potential applications in various industries. Some of the most promising applications are:

- Aerospace: FGMs can be used to create lightweight and strong parts with varying material properties, making them ideal for aerospace applications.

- Biomedical: FGMs can be used to create implants with varying material properties, ensuring proper compatibility with the human body.

- Automotive: FGMs can be used to create parts with varying material properties, resulting in better fuel efficiency and performance.

V. Advantages and Disadvantages of FGMs 3D Printing

FGMs 3D printing offers several advantages over traditional manufacturing methods. Some of these advantages include:

- Design freedom: FGMs 3D printing allows for the creation of complex parts with varying material properties, which is not possible with traditional manufacturing methods.

- Cost-effective: FGMs 3D printing can help reduce material waste and overall costs in manufacturing.

- Lightweight parts: FGMs 3D printing can help create lightweight parts, reducing the overall weight of the product.

The disadvantages of FGMs 3D printing include:

- Complexity: FGMs 3D printing involves the use of multiple materials and complex design software, which can be time-consuming and challenging.

- Quality control: Ensuring consistent quality across a part can be challenging in FGMs 3D printing.

VI. Future of FGMs 3D Printing

The future of FGMs 3D printing looks promising. As the technology advances, it is expected to become more widely used in different industries. Researchers are already experimenting with new materials and techniques to improve the efficiency and quality of FGMs 3D printing.

VII. Conclusion

FGMs 3D printing is a breakthrough in material science. It offers several advantages over traditional manufacturing methods and has the potential to revolutionize the way we design and manufacture complex parts. As the technology advances, we can expect to see more FGMs 3D printing applications in different industries, leading to better products and more efficient manufacturing processes.

- What is Functionally Graded Material by Additive Manufacturing?

Functionally Graded Material (FGM) in additive manufacturing refers to a type of material that exhibits a gradual and controlled change in composition, structure, or properties over its volume. In other words, it is a material where the properties gradually transition from one end to another, allowing for customized and tailored performance across the structure.

In additive manufacturing, FGM is achieved by strategically combining different materials or adjusting material properties during the 3D printing process. By precisely controlling the composition and distribution of materials, additive manufacturing techniques can create parts with unique properties and functionalities, catering to specific engineering requirements.

The ability to fabricate FGM through additive manufacturing opens up exciting possibilities for designing components with optimized mechanical, thermal, or electrical properties. This technology is particularly valuable in applications where traditional homogeneous materials would not offer the desired performance, such as in aerospace, automotive, and biomedical industries.