An LCD light-curing 3D printer, also known as an LCD resin 3D printer or a UV resin 3D printer, is a type of additive manufacturing device that utilizes liquid photopolymer resins to create three-dimensional objects. The internal structure of an LCD light-curing 3D printer consists of several key components that work together to facilitate the printing process:

1. LCD Screen

The central component of an LCD light-curing 3D printer is the LCD screen (liquid crystal display). The LCD screen is positioned at the bottom of the resin vat and serves as the light source for curing the photopolymer resin. It displays each layer of the 3D model as a 2D image using ultraviolet (UV) light, selectively blocking or allowing UV light to pass through based on the image data.

2. Resin Vat

The resin vat is a container that holds the liquid photopolymer resin. It is situated just above the LCD screen. The vat is typically made of a transparent material that allows UV light to pass through without affecting the curing process. The LCD screen projects each layer's image onto the surface of the resin, causing the exposed resin to solidify.

3. Build Platform

The build platform is a movable platform that holds the object being printed. It is initially positioned at the bottom of the resin vat. As each layer is cured, the build platform gradually moves upward, allowing the newly solidified layer to separate from the bottom of the vat. This process is repeated for each subsequent layer until the entire 3D model is complete.

4. Z-Axis Stepper Motor and Lead Screw

The Z-axis stepper motor and lead screw are responsible for controlling the vertical movement of the build platform. The stepper motor rotates the lead screw, which in turn raises or lowers the build platform with precision, ensuring accurate layer-by-layer printing.

5. UV Light Source

Above the resin vat, there is an array of UV LED lights that emit ultraviolet light. The UV light cures the exposed resin on the LCD screen, causing it to solidify and adhere to the previous layers. The use of UV LEDs allows for faster curing times compared to other light-curing methods.

Factors Affecting Printing Speed in LCD Light-Curing 3D Printers

The printing speed in an LCD light-curing 3D printer can be influenced by several factors:

1. Layer Thickness

The layer thickness, also known as the layer height, refers to the vertical distance between each printed layer. A smaller layer thickness results in finer details but may increase the printing time. Larger layer thicknesses can speed up the printing process but may sacrifice some surface quality.

2. UV Light Intensity

The intensity of the UV light emitted by the LED array affects the curing speed of the resin. Higher UV light intensity can lead to faster curing times, enabling quicker printing. However, it is essential to balance the light intensity to ensure proper curing and avoid overexposure.

3. Resin Viscosity

The viscosity of the liquid photopolymer resin plays a role in printing speed. Lower viscosity resins flow more easily, which can lead to faster printing. However, the choice of resin viscosity must be balanced with the desired mechanical properties and surface finish of the printed object.

4. Print Settings and Exposure Time

The exposure time for each layer, which determines how long the UV light cures the resin, can significantly impact printing speed. Optimizing print settings, including exposure time and layer cure time, can help achieve faster print speeds without compromising print quality.

5. Complexity and Size of the Model

The complexity and size of the 3D model being printed also affect the overall printing time. More intricate designs and larger objects will require more time to print than simpler and smaller models.

6. Print Resolution

Higher print resolutions require more layers to build the object, leading to longer printing times. Adjusting the print resolution based on the application's requirements can help balance speed and quality.

Conclusion

LCD light-curing 3D printers are sophisticated devices that rely on precise coordination of their internal components to produce detailed and accurate 3D prints. The combination of factors such as layer thickness, UV light intensity, resin viscosity, print settings, model complexity, size, and print resolution all contribute to the overall printing speed. By carefully optimizing these factors, users can achieve faster and more efficient 3D printing without compromising the quality of the final printed objects.

The most common types of light-curing 3D printers are SLA, DLP and LCD, among which LCD is the most widely used, it is much faster than SLA in forming, and cheaper than DLP and SLA. So here is a small analysis of the internal structure of the LCD light-curing 3D printer and its factors that will affect the printing speed.

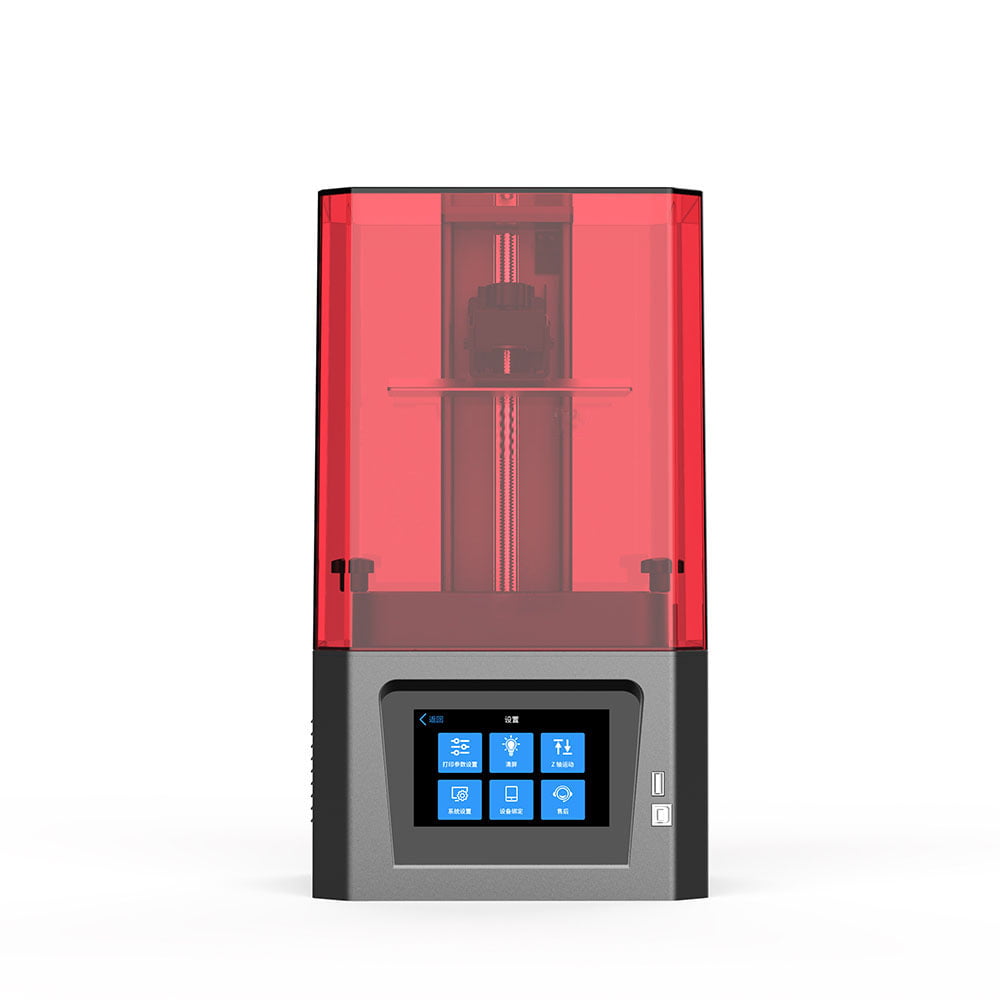

The structure of LCD3d printer

The overall internal structure is: 1, light source, 2, focusing lens, 3, Fresnel lens, 4, polarizing film, 5, LCD screen, 6, polarizing film, 7, reservoir tank bottom film, 8, light curing resin, 9, curing molding parts tray.

Some factors that affect the printing speed

1, the intensity of the light source. Resin for printing technology is applied to the light source irradiation curing photosensitive resin, and the three different light sources we mentioned above, in speed, dlp > lcd > sla, in addition to the actual light source is able to determine the speed of printing based on the intensity.

2, layer thickness. Not only speed, model accuracy will also have a corresponding impact. The thicker the layer, the more time saved when printing, because if we cut software to cut the thickness, the fewer layers we need, the faster the printing speed, the cost of doing so is obviously, sacrificing speed to get a low-quality model, which is obviously not what we want to see, therefore, in the layer thickness selection, you need to grasp the degree.

3, the material. The selection of resin materials, because different monomers, prepolymers, photoinitiators and other additives combined into the resin, can directly cause different material properties and different curing times, at this stage, the market is also continuing to develop new resin materials to maximize the needs of various industries.

- The model itself. Assuming that the model itself is hollow, if there are not so many small details, the printing speed will be faster. In addition, also highlighted the placement of the model. Usually, it is placed vertically accordingly. Because light-cured 3D printers are height-based, vertical placement takes more time. The benefit of this is that the accuracy of each layer can be significantly improved, and it is good to get better molding results at the cost of speed.