Table of Contents:

- Introduction to Precision CNC Milling

- How CNC Milling Works

- Benefits of Precision CNC Milling

- Materials Used in CNC Milling

- Applications of Precision CNC Milling

- Quality Control in CNC Milling

- Choosing the Right CNC Milling Service

- Conclusion

-

1.Introduction to Precision CNC Milling

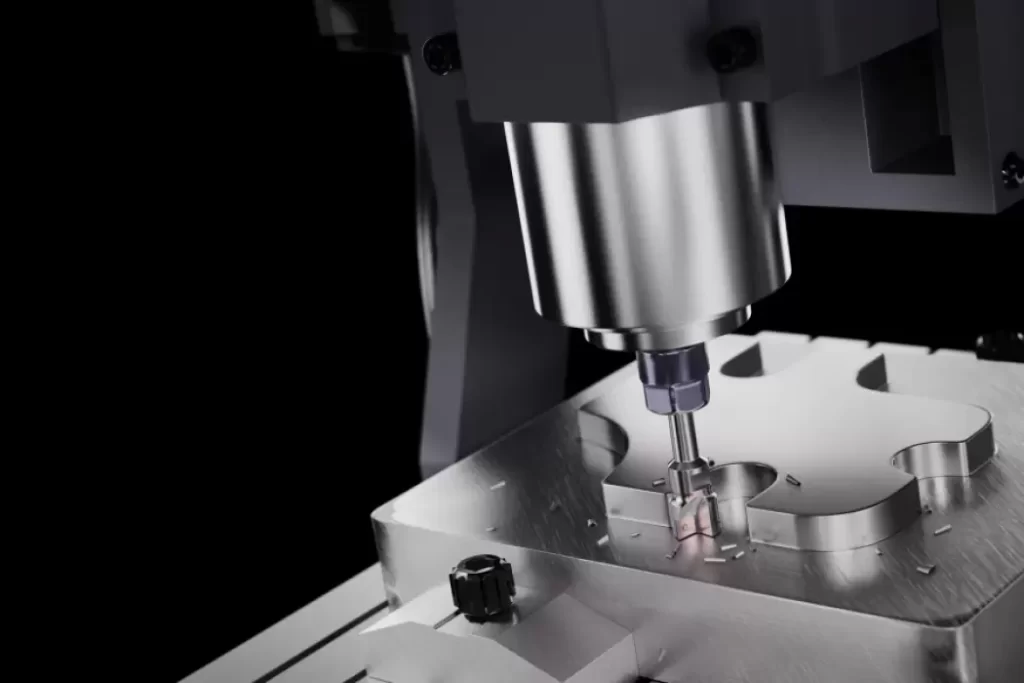

CNC milling is an automated process of using computer controls to operate machine tools with the goal of creating precise and complex parts. The process is favored for its accuracy and production efficiency, making it suitable in various industries. The machines used for CNC milling are typically automated and operate based on pre-programmed software that guides them to cut, shape and drill materials to exact specifications.

With the use of CNC milling machines, complex shapes can be cut with precision and consistency not possible with traditional methods. The program used by the machine will guide it to move along the material in various directions, making repetitive and intricate cuts without the need for manual intervention.

-

2.How CNC Milling Works

CNC milling machines work by using a rotating cutting tool to cut away the material, creating the desired shape according to the programmed design. The computer-controlled machine will move the cutting tool along multiple axes, including x, y, z, and other axes depending on the machine type, to produce the completed part.

CNC Milling Process Steps

The CNC milling process typically involves the following steps:

- Designing the part

- Developing a program that instructs the machine how to cut the part

- Preparing the material to be cut

- Setting up the CNC milling machine so that it can execute the program in accordance with the design specifications

- Running the machine to produce the desired part

- Inspecting and testing the finished part for accuracy and quality control.

Types of CNC Milling Machines

CNC milling machines vary in size, design, and method of operation, and the choice of the machine depends on the specific requirements of the project. Some of the main types of CNC milling machines include:

- Vertical Milling Machines: These machines are the most common type of CNC milling machines and commonly used for producing parts with complex shapes.

- Horizontal Milling Machines: These machines are used for performing tasks that require a higher level of precision.

- Gantry Milling Machines: Gantry milling machines have large working spaces, making them useful for producing larger components.

- Bed Milling Machines: Bed milling machines have a rotary table that can be used to move the workpiece in a variety of directions, making them ideal for creating complex shapes.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

During the CNC milling process, the computer program that guides the machine is typically created with Computer-aided design (CAD) and Computer-aided manufacturing (CAM) software. CAD is a software program used by engineers and designers to create accurate 3D models of parts that they wish to have manufactured. CAM software is then used to transfer the CAD file into a language that the CNC milling machine can understand.

-

3.Benefits of Precision CNC Milling

There are various benefits of precision CNC milling that make it a popular method of manufacturing complex components. Some of these benefits include:

- Precision and Consistency: CNC milling machines are known for their accuracy in producing parts consistently, ensuring that each part meets the same level of quality and specifications.

- Efficient Production: CNC milling machines can produce parts in large quantities quickly and efficiently, reducing production time and cost.

- Flexibility: CNC milling machines can handle a wide range of materials, including metals, plastics, and composites, allowing for design flexibility and versatility.

- Reduced Labor Costs: CNC milling machines require minimal manual intervention, reducing the labor cost involved in manufacturing high-quality parts.

-

4.Materials Used in CNC Milling

CNC machines can work with various materials, depending on the specific requirements of the part being produced. Some of the materials that can be processed using CNC milling include:

- Metals: Metals are commonly used in the manufacturing process and can be processed into various shapes and sizes.

- Plastics: Plastics are favored for their durability, flexibility, and resistance to wear and tear.

- Composites: Composites, made by combining multiple materials, are used in aerospace and automotive industries for their strength and lightweight properties.

-

5.Applications of Precision CNC Milling

CNC milling finds its applications in various industries that produce complex components. Some of the industries that frequently use CNC milling include:

- Aerospace Industry: High precision is required in the aerospace industry, and CNC milling is often used to produce complex parts for airplanes and spacecraft.

- Medical Industry: CNC milling is used to manufacture parts for medical devices and implants.

- Automotive Industry: The automotive industry frequently uses CNC milling to produce complex components for automobiles.

- Defense Industry: CNC milling is used in the defense industry to produce components for military equipment.

- Electronics Industry: CNC milling is used to create components for electronic devices, including computer parts and memory chips.

If you need about CNC Milling Services,You can click on the V1 Prototype website to find it.

-

6.Quality Control in CNC Milling

Quality control is critical in the CNC milling process, and manufacturers have to adhere to strict standards to ensure that the finished products meet the specifications outlined in the program. The quality control process can include various methods, including inspecting the parts for accuracy, checking the dimensions of the components produced, and ensuring that the final product meets industry standards and regulations.

-

7.Choosing the Right CNC Milling Service

When selecting a CNC milling service, it is essential to choose a provider who is experienced and has a reputation for producing high-quality components. Factors to consider when choosing a CNC milling service include:

- Technical Expertise: The provider should have experience in producing parts with complex geometries and tight tolerances.

- Quality Control Procedures: The provider should have a system in place for comprehensive quality control, including inspection and testing of components for accuracy and meeting industry standards.

- Materials Used: The provider should have experience working with a range of materials, including metals, plastics, and composites.

- Cost: The cost of CNC milling services can vary, and it is important to balance quality with cost-effectiveness.

.

Questions to Ask a CNC Milling Service Provider

When selecting a CNC milling service provider, it is essential to ask questions that will help assess their expertise and experience. Some questions to ask include:

- What type of CNC milling machines do you have and what capabilities do they offer?

- Have you worked on projects similar to mine before? Can you provide examples of similar projects completed in the past?

- Do you have any certifications or do you meet industry-specific regulations and standards?

- What quality control procedures do you have in place?

-

8.Conclusion

Precision CNC milling has revolutionized the manufacturing industry, providing a cost-effective and efficient method for producing complex components. With this advanced manufacturing technology, high-quality components can be produced with precision and consistency, meeting the specifications and requirements of various industries.

Choosing the right CNC milling service provider is essential to obtaining high-quality components that are customized to fit your specific needs. When selecting a provider, it is important to consider their experience, technical expertise, and quality control procedures.

By understanding the CNC milling process and the benefits it can provide, manufacturers can make informed decisions on whether this technology is the right solution for their operations. With CNC milling, companies can produce high-quality components quickly and efficiently, giving them a competitive edge in today’s fast-paced manufacturing industry.