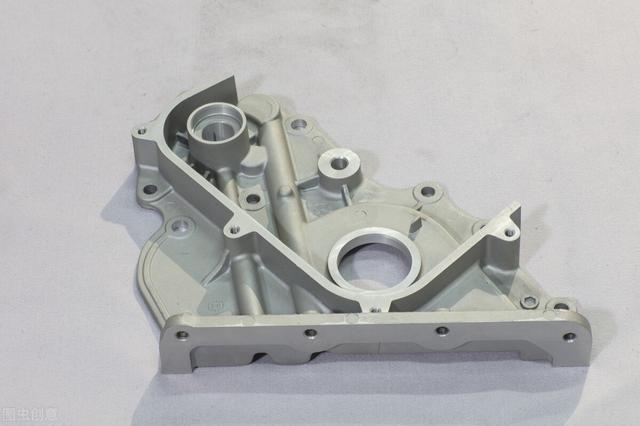

The application of CNC machining or SLA laser rapid prototyping manufacturing prototype, that is, turning over the hand board, so that it has a clear view and understanding of its construction and appearance, then, before the manufacture of silicone moulds, we need to understand its shape and structure. That is, to understand its prototype, the use of silicone moulds in hand board factories can make more than 20 similar products.

The processing and manufacturing method of hand board

CNC hand board is a more common and commonly used hand, not only because of its mature technology, a part of its material is very special, such as silicone, the price of this material is not very expensive, but the quality is very guaranteed, then it is a complex introduction to you. Silicone hand I this is one of the ways to manufacture hand board.

The advantages of the silicone board secondary focus on the consumption of work fast, low cost, high failure rate, we should do what do not have to worry, the manufacture of hand board tips you, you can use CNC CNC machining or SLA laser rapid prototyping manufacturing prototype, that is, turn over a hand board, then its structure and appearance will have a clear view and understanding. e mold, we need to understand its shape and structure, that is, to Understand its prototype, the use of hand board factory silicone moulds can make more than 20 similar products.

The fixed nature of the hand board factory SLA material invites the high precision and efficiency of equipment that can only be made from certain specific products

The advantage of the hand board factory SLA hand board is quickly formed, ordinary products if CNC processing, then the work required for dozens of hours, the next machine will require manual bonding, grinding and other processes, a total of 2-3 days, and as SLA, it is not affected by the complexity of the product S. The construction, which can be composed as a whole, the product is a whole, saving the work and cost of subsequent manual grinding and attachment, etc. The process saves a small amount of process, and high precision, now SLA speed forming machine precision can reach 0.05mm or so, the general product precision can be fully satisfied.

What is SLA 3D Printing Process?

SLA 3D Printing, also known as Stereolithography, uses a liquid photopolymer that solidifies with the help of lasers. The resin is cured by a laser beam that solidifies the material layer by layer creating an object. The process begins with selecting a design model and uploading it to the SLA 3D printer. The printer then manufactures the object by depositing the resin layer-by-layer based on the model's specifications. A UV laser emits the cross-sectional pattern of the object onto a vat of the photosensitive resin, solidifying one layer at a time until the object is fully formed.

SLA 3D printing offers several advantages over other printing methods, and it is ideal for creating objects with high precision and fine details making it ideal for prototyping and modeling applications.

What is the Manufacturing Method of 3D printing?

The manufacturing method of 3D printing is a process that creates a digital model using Computer-Aided Design (CAD) software. The software slices the modeled object into layers, which are then sent to the 3D printer. The printer then creates the object by depositing material layer-by-layer, based on the model's specifications. The method of 3D printing can utilize various materials such as metal, plastic, and resin.

What Method of 3D Printing is Used for Modeling, Prototyping, and Production Applications?

While there are several 3D printing processes, each with unique characteristics and applications, SLA 3D printing is the most commonly used method for modeling and prototyping applications. The reason for this is its ability to produce highly detailed and accurate objects with fine details. When it comes to production applications, other methods such as Fused Deposition Modeling (FDM) are frequently used, as they're faster and more cost-efficient.

What is the Manufacturing Process of Stereolithography?

Stereolithography is the method used in the SLA 3D printing process. It is a manufacturing process that involves utilizing 3D printing technology. Its process starts with a vat of liquid photopolymer that is solidified into a 3D object. The process begins by selecting a design model and uploading it to the printer. A UV laser then emits a cross-sectional pattern of the object onto the vat of resin, solidifying one layer at a time until the object is fully formed. The resin hardens when exposed to light, and the process continues until the entire object is created.

Conclusion

The SLA 3D Printing and Stereolithography are becoming increasingly popular in the manufacturing industry due to the advantages they offer. The processes provide cost-effective and efficient solutions for creating complex and detailed objects. By understanding the 3D Printed SLA Hand Model Production Method, businesses can create prototypes and models quickly and efficiently, leading to better product development and accelerated innovation. As technology advances, 3D Printing processes will continue to improve, bringing even greater benefits to businesses worldwide.