Table of Contents:

- Introduction

- Disadvantages of 3D Printing

- Discussion and Analysis

- Conclusion

-

1.Introduction

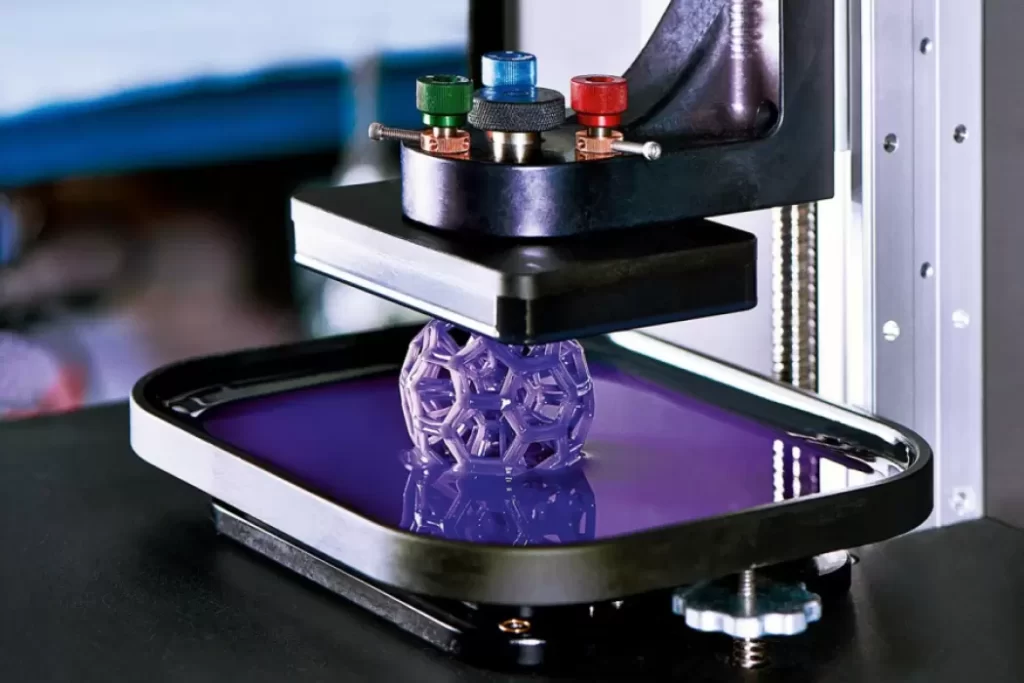

The advent of 3D printing has revolutionized the way we create and design products, and it has become an essential tool in various industries such as aerospace, automotive, and healthcare. 3D printing technology has brought about numerous benefits such as improved customization, faster production times, and reduced costs. However, like any technology, 3D printing has its disadvantages that limit its potential use. In this article, we will explore the disadvantages of 3D printing and how they affect the industry’s growth.

-

2. Disadvantages of 3D Printing

A. Limited Materials:One significant disadvantage of 3D printing is the limited range of materials that can be used. Most 3D printing machines can only print with a limited number of materials such as plastics, metals, and ceramics. This limitation makes it challenging to create products that require specific properties such as flexibility or durability. Moreover, some materials used in 3D printing can be expensive, which makes 3D printing costlier than traditional manufacturing methods.

B. Quality Control Issues:Quality control is an essential aspect of any manufacturing process, and 3D printing is no exception. One of the significant issues with 3D printing is the difficulty in achieving consistent quality. The quality of the final product depends on several factors such as the printer’s calibration, the printing material’s quality, and the printer’s software. Inconsistent quality can lead to products that are not fit for purpose or do not meet the required standards.

C. Costly Equipment and Maintenance:Another disadvantage of 3D printing is the high cost of equipment and maintenance. 3D printers can be expensive to purchase and maintain, which can make it difficult for small businesses or individuals to use this technology. Moreover, the cost of repairing 3D printers can be high, and it may require specialized technicians to fix them, leading to additional expenses.

D. Time Consuming:3D printing can be a time-consuming process, especially for complex designs or large products. Unlike traditional manufacturing methods, which can produce thousands of products in a short time, 3D printing can only produce a limited number of products at a time. This can be a significant disadvantage for businesses that require large volumes of products within a short time.

E. Environmental Concerns:3D printing can also have environmental implications. The materials used in 3D printing are not always environmentally friendly, and the printing process can produce waste and emissions. Moreover, 3D printing requires a significant amount of energy, which can contribute to greenhouse gas emissions.

-

3. Discussion and Analysis

A. Exploring the Limitations:While 3D printing has brought about numerous benefits, its limitations have hindered its potential use. The limited range of materials and the difficulty in achieving consistent quality can limit the types of products that can be produced. Additionally, the high cost of equipment and maintenance, as well as the time-consuming nature of the process, can be a significant disadvantage for businesses.

B. Challenges and Issues:There are also several challenges and issues facing the 3D printing industry. One of the significant issues is the lack of standardization in the industry. With no universally accepted standards, it can be challenging to compare different printers or materials, which can make it difficult for businesses to choose the right equipment.

C. Addressing the Drawbacks:To address the drawbacks of 3D printing, researchers and industry experts are continually working on improving the technology. For example, new materials are being developed that can increase the range of products that can be printed. Moreover, efforts are being made to improve the consistency of the printing process and reduce the time it takes to print products. Additionally, there are initiatives to make 3D printing more environmentally friendly by using sustainable materials and reducing waste.

-

4. Conclusion

In conclusion, 3D printing has its advantages and disadvantages, and it is crucial to consider both when deciding whether to use this technology. The limited range of materials, quality control issues, high cost of equipment and maintenance, time-consuming nature of the process, and environmental concerns are significant disadvantages of 3D printing. However, with ongoing research and development, these limitations can be overcome. Therefore, businesses should carefully consider their needs and requirements before deciding whether to use 3D printing or traditional manufacturing methods.