Blog Center

Additive Manufacturing for Aerospace and Space: Revolutionizing the Industry

Explore the groundbreaking applications of additive manufacturing in the aerospace and space industries. This comprehensive article delves into the use of additive manufacturing technologies in aircraft and spacecraft production, highlighting the benefits, challenges, and future prospects. Discover how additive manufacturing is transforming the way we design, manufacture, and operate in...

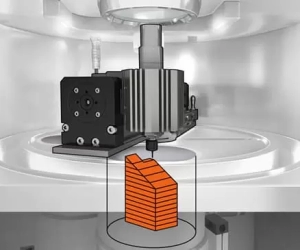

Exploring Metal and Hybrid Systems in Additive Manufacturing

Dive into the fascinating world of metal and hybrid systems in additive manufacturing. This comprehensive article sheds light on the innovative technologies and processes used in metal additive manufacturing, as well as the emerging field of hybrid systems. Explore the advantages, applications, and challenges of utilizing metal and hybrid systems...

Top 3D Printer Material Companies: Innovators in Additive Manufacturing

Explore the world of 3D printer material companies and discover the innovative materials shaping the additive manufacturing industry. This comprehensive article showcases the leading companies in the field, highlighting their contributions, materials, and advancements. Gain insights into the exciting developments and find out how these companies are revolutionizing the possibilities...

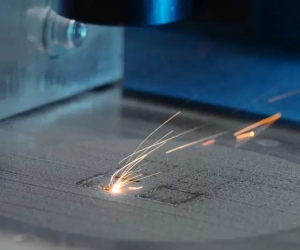

The Power of Laser in Additive Manufacturing

Discover the significant role of lasers in additive manufacturing and explore how this cutting-edge technology is revolutionizing the manufacturing industry. This comprehensive article provides insights into the various aspects of using lasers for additive manufacturing, including its principles, advantages, applications, and challenges. Gain a deeper understanding of how lasers are...

Understanding the Direct Process in Additive Manufacturing

Explore the fascinating world of additive manufacturing and delve into the intricacies of the direct process. This comprehensive article provides insights into the various aspects of direct processes in additive manufacturing, including its definition, advantages, applications, and challenges. Gain a deeper understanding of this cutting-edge technology and its potential to...

The Design Cave: Unleashing Creativity with 3D Printing

Step into the world of the Design Cave and discover how 3D printing is revolutionizing the creative process. Explore the benefits, applications, and future possibilities of incorporating 3D printing into your design workflow. Table of Contents: 1. Introduction In the realm of design, creativity knows no bounds. The Design Cave...

Exploring the Sheet Additive Manufacturing Process: A Comprehensive Guide

Discover the innovative world of sheet additive manufacturing. This comprehensive guide explores the process, benefits, applications, and future prospects of this cutting-edge technology. Table of Contents: 1. Introduction In recent years, additive manufacturing has revolutionized the manufacturing industry by enabling the production of complex and customized parts with ease. One...

Common Manufacturers of the 3D Printing Industry: A Comprehensive Guide

Explore the world of 3D printing and learn about the common manufacturers in the industry. Discover the leading companies that are shaping the future of additive manufacturing. Table of Contents: 1. Introduction The 3D printing industry has witnessed remarkable growth and innovation over the years, transforming the way products are...

SLS Rapid Prototyping Factory: Revolutionizing Product Development

Discover how SLS rapid prototyping factories are transforming the product development landscape. Explore the benefits, applications, and future prospects of this advanced manufacturing technology. Table of Contents: 1. Introduction In today's fast-paced world, innovation is key to success. One of the key components of innovation is the ability to quickly...

Finding the Perfect SLA Prototype Supplier: Unlocking Manufacturing Potential

Discover the importance of choosing the right SLA prototype supplier and how it can revolutionize your manufacturing process. Explore the differences between SLA and SLS prototyping methods and understand the role of SLA in manufacturing. This comprehensive guide will provide insights into the world of SLA prototypes and help you...

Revolutionizing Manufacturing: The Power of SLA Prototype Factory

Explore the fascinating world of SLA prototype factory and its impact on modern manufacturing. Discover the benefits, applications, and differences between SLA and SLS prototyping methods. Gain insights into how SLA is transforming the industry and revolutionizing the way products are brought to life. Table of Contents: 1. Introduction In...

Reverse Engineering with 3D Printing

Reverse engineering combined with 3D scanning and printing offers a powerful and innovative approach to product development and manufacturing. This article explores the process of incorporating 3D scanning and 3D printing techniques in reverse engineering and highlights the benefits of this combination. Introduction Defining Reverse Engineering and Its Relevance to...

The Future of Precision Machining in China

The future of precision machining in China looks promising, with advancements in technology and increasing demand for high-quality components. This article explores the potential developments and opportunities in the field, considering the future of machining as a whole, the role of machinists, and the ongoing importance of precision machining. Advancements...

How to Choose the Right Precision CNC Machining Supplier for Your Business

Selecting the right precision CNC machining supplier is crucial for the success of your business and ensuring high-quality manufactured components. This guide provides valuable insights into determining the ideal machining supplier for your specific needs, taking into account factors such as capabilities, expertise, quality standards, and customer support. Evaluate the...

5 Benefits of Partnering with Precision CNC Machining Suppliers

Partnering with precision CNC machining suppliers offers numerous advantages in terms of manufacturing efficiency, quality, and flexibility. This article explores the five key benefits of collaborating with CNC machining suppliers who specialize in delivering high-precision components and parts. Access to advanced technology and equipment In today's rapidly advancing technological landscape,...

Machining Companies Near Me: A Comprehensive Guide

Finding machining companies near your location is essential for businesses or individuals seeking professional CNC machining services. These companies offer a wide range of capabilities and expertise in precision manufacturing processes. They utilize advanced CNC (Computer Numerical Control) machines to produce high-quality parts with incredible accuracy. CNC machining involves the...

How to Choose the Right CNC Machining Parts Supplier

Selecting the right CNC machining parts supplier is critical for ensuring high-quality products and a reliable supply chain. When making this important decision, there are several factors to consider. Evaluating the supplier's experience and expertise When it comes to choosing a CNC machining parts supplier, one of the most important...

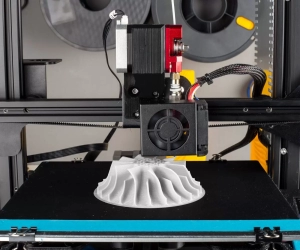

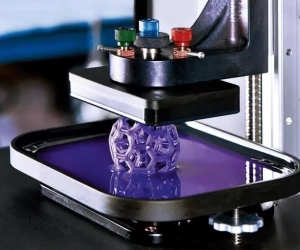

The Future of 3D Printing Services: Trends and Innovations to Watch

As 3D printing continues to advance, the future holds exciting possibilities and transformative changes across various industries. The following trends and innovations are set to shape the future of 3D printing services. Increased use of 3D printing in healthcare and bioprinting Introduction The healthcare industry has been one of the...

The Benefits of Using 3D Printing Services for Rapid Prototyping

Faster Turnaround Times The use of 3D printing services can significantly reduce the time it takes to create prototypes, allowing for faster product development. How 3D Printing Services Can Speed Up Product Development One of the biggest advantages of using 3D printing services for rapid prototyping is that it eliminates...

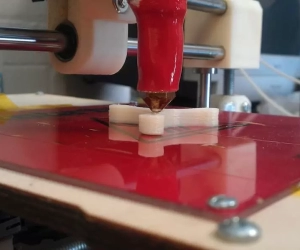

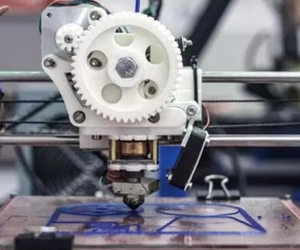

How 3D Printing Services are Revolutionizing the Manufacturing Industry

The title captures the transformative impact of 3D printing services on the manufacturing industry. 3D printing, also known as additive manufacturing, has emerged as a groundbreaking technology that is reshaping traditional manufacturing processes. This description explores the ways in which 3D printing is revolutionizing the industry and highlights its role...