Rapid Tooling Service

Rapid Tooling with more flexibility, low cost, volume speed, finishing for your upcoming products

Rapid Tooling Service

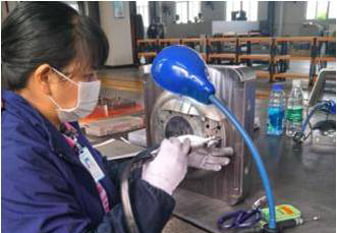

V1 Industrial has the most advanced facilities, the expertise of prototyping, skillful personnel and rigorous management to offer you the high-quality rapid tooling, prototyping and die casting parts.

Using your qualified CAD drawings in our proprietary OMS system,one toolmaker will take charge of your projects from beginning to finish to ensure the quality and fast lead time from the rapid prototypes to thousands of production volumes.

Rapid Tool making Process

All projects and manufacturing processes come with their own challenges to and guidelines for success. For rapid prototyping there are a number of things you can do to reduce the cost and lead time.

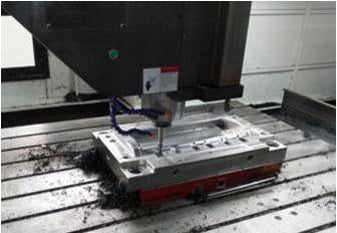

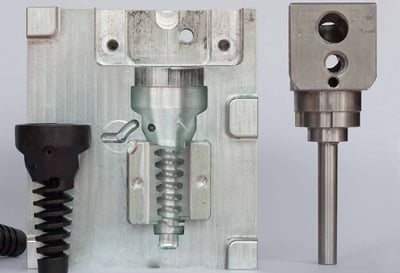

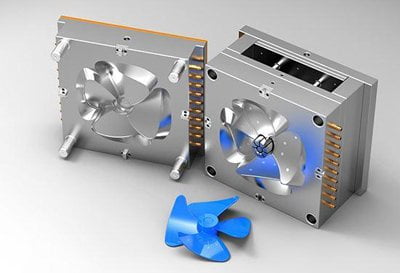

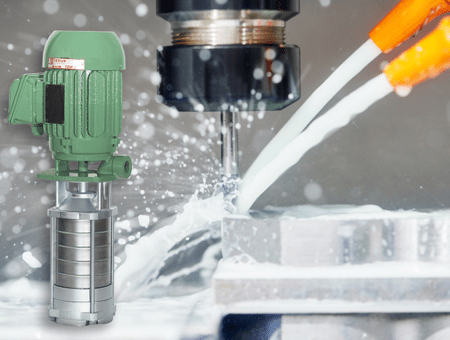

Your rapid mold tools are made with high-quality P20, Nak80 or H13 tool steels. We use imported multi-axis CNC mills, grinders and EDM machines to create complex geometries with multiple surface finishes, from the highest optical polishes to matte and everything in between. We can even apply custom textures using Mold photoetching. Our partnership with Germany ensures that only the finest cutting tools are used to maximize speed while holding tight tolerances in any material.

Advantages of Toolmaking Service

When you choose V1 Industrial for quick turnaround mold tools, you get a host of services to support any project, including:

- Design for Manufacturing analysis

- Overmolding

- Multiple cavities

- Inserts

- Heated cores

- Manual and hydraulic sliders

- And much more!

Rapid Tooling Material Verification

We use X-ray fluorescence and spectrophotometry to measure the precise molecular composition of all the raw materials we use for your tooling. You can be assured you get exactly the material grade you specify.

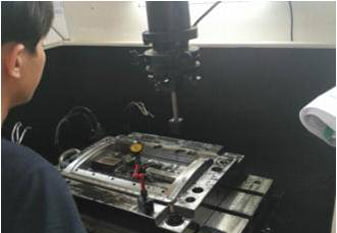

Our attention to detail doesn’t stop when your mold is completed. We’re not satisfied until your finished parts have been fully verified in our modern quality control metrology lab.

Why Choose V1 Company for Rapid Tooling?

√ Excellent Efficiency with Mass-Production Quality

√ A Proven Proprietary OMS System

Our proprietary One Man One Mold OMS system allows a single master toolmaker to take charge of your project from start to finish. Simply give us your qualified CAD drawings, and we’ll handle the rest. Rapid tooling has never been this easy, or this fast.

√ Intelligent Pricing for Every Project

√ Industry-Leading Equipment, Uncompromised Testing

√ Design for Manufacturing Support

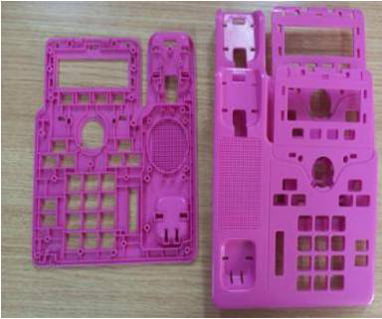

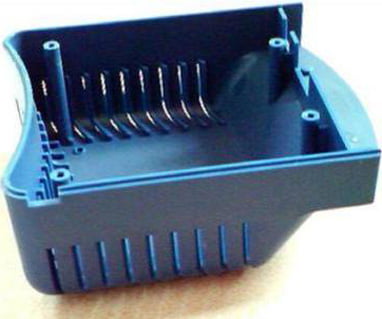

Rapid prototyping is one of injection molded parts

Rapid Tooling Applications

Prototypes can be made in different materials such as plastic, aluminum alloy,steel etc and can be used in different industries like Automotive, Home Appliances, Office equipment, Industrial using, Medical industry and so on.