Rapid Prototyping Services

Low to high-volume production, assisting your high-quality plastics and Metal parts.

Rapid Prototyping Services

Process introduction

Design and mass assembly according to different customer needs.

What can we do

One stop rapid manufacturing + medium and small batch customization

Quick sample

3D printing - CNC hand board

CNC small batch processing

Various engineering plastics and aluminum alloys

Rapid tooling

Silicone mold, resin mold

Medium and small batch production

Multi process integration

Trial assembly

Small Volume Production Technology Series

According to the needs of customers, providing various production solutions to customers for their choice.

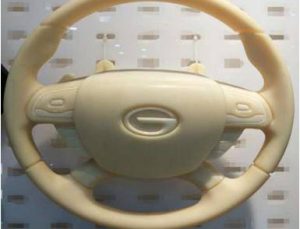

RIM

Low cost for molds, short development cycle,no limited wall thickness, much freedom for product design, wide field of application, good material performance, corrosion resistance, suitable for small volume production!

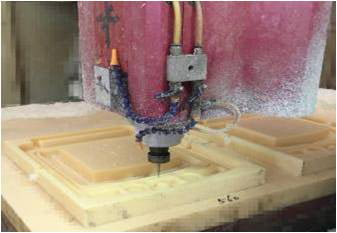

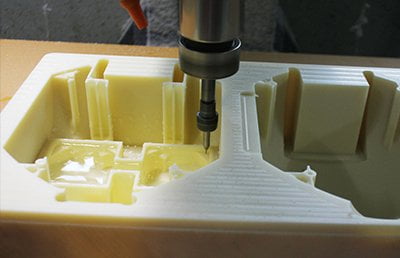

CNC machining

CNC can directly process the required products via programming the three-dimensional data, splitting, high precision machining. All processed parts can be sprayed, electroplated, silk-screened, coated and other surface treatments, which can be assembled, better reflects the design function.

RTM process

RTM is short for resin transfer molding, it is a low-pressure closed-molding technology, paved the preformed fibrous fabric in a closed cavity, inject the resin contained filler, curing agent, accelerator into the mold cavity for solidification. Large overall composite components are easily produced by RTM, which is widely used in aircraft manufacturing, medical shells, cover areas for large products.

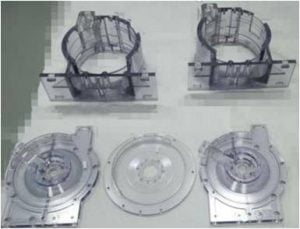

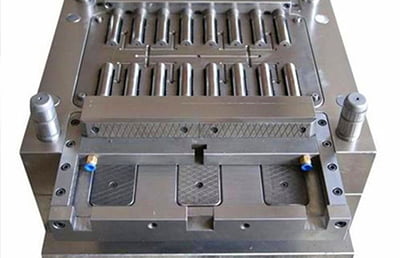

Soft steel mold

Soft steel mold uses the formal production process, product materials can meet the performance requirements of formal materials, It’s suitable for high requirements of material properties and structures. The mold is soft steel, such as P20,718 and other materials.RTM can Simplify mold design, save mold development costs and cycles.

Rapid Prototyping Product application