This guide provides a comprehensive overview of how to calculate the manufacturing costs associated with 3D printing. It covers the various factors that contribute to the overall cost, including materials, equipment, labor, and more. By following the step-by-step instructions outlined in this guide, readers will gain a better understanding of how to accurately estimate the cost of 3D printing-based manufacturing and make informed decisions about their production processes.

I. Introduction

A. The Importance of Understanding Manufacturing Costs

In the dynamic landscape of modern manufacturing, grasping the nuances of production expenses transcends mere number crunching; it's about safeguarding the longevity and profitability of your enterprise. This comprehensive guide is crafted to unravel the intricacies of calculating 3D printing way manufacturing costs, offering you a detailed exploration of the financial terrain inherent in this cutting-edge process.

B. What is 3D Printing?

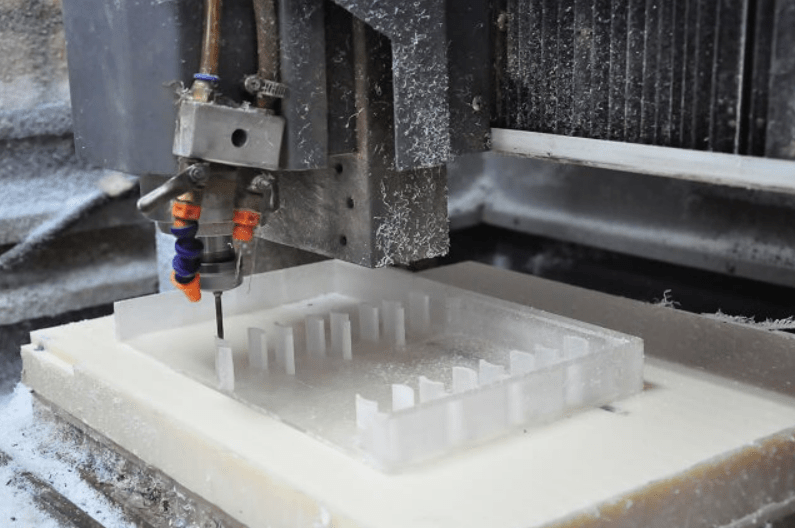

Before delving into the intricacies of cost calculation, it's imperative to establish a solid comprehension of the technology under scrutiny. 3D printing, also known as additive manufacturing, is a revolutionary process wherein three-dimensional objects are meticulously crafted layer by layer from digital models. A profound understanding of this technology forms the bedrock for evaluating the costs intricately interwoven with it.

C. The Costs Involved in 3D Printing

While 3D printing bestows unparalleled design freedom and flexibility, it is not devoid of associated costs. Material expenditures, equipment investments, and skilled labor requisites merely scratch the surface. This guide is poised to systematically dissect the myriad cost components, presenting you with a structured roadmap to navigate the complex financial realm of 3D printing.

II. Calculating Material Costs

A. Determining Material Requirements

Design Considerations

The crux of material cost calculation lies in navigating the intricate terrain of your design. The complexity of geometries, intricacy of details, and variability in structures can significantly sway the type and volume of material required. A judicious evaluation of these design considerations sets the stage for precise cost estimations and minimizes material wastage.

Quantity and Weight of Material Needed

Precision in projecting the quantity and weight of materials needed is paramount. From filament spools to resin volumes, a meticulous evaluation ensures that cost estimations are accurate and guards against unnecessary wastage. Striking a delicate balance between meeting design requirements and optimizing material consumption is key.

B. Purchasing Materials

Sourcing Materials

The strategic choice of suppliers is pivotal. The reliability of the supply chain, material quality, and the supplier's reputation are critical factors influencing the trajectory of your costs. Establishing robust relationships with trustworthy suppliers lays the foundation for a stable and cost-effective material procurement process.

Negotiating Prices

The art of negotiation can yield substantial cost savings. Cultivating long-term relationships with suppliers and leveraging bulk purchasing power are indispensable tactics for securing favorable material prices. Continuous negotiation and awareness of market dynamics contribute to an agile and cost-effective supply chain.

C. Material Costs Analysis

An in-depth analysis of material costs extends beyond initial calculations. Vigilant monitoring of material prices, technological advancements, and exploration of alternative materials should be integrated into an adaptive strategy. This ongoing analysis ensures that material costs remain optimized in the ever-evolving landscape of 3D printing.

III. Calculating Equipment Costs

A. Acquiring 3D Printers

Types of 3D Printers

Diverse printing technologies come with varied costs. Delving into the intricacies of each, from Fused Deposition Modeling (FDM) to Stereolithography (SLA), aids in making informed decisions aligned with your production requirements and financial constraints.

Purchasing Considerations

Choosing the right printer involves weighing factors like print speed, resolution, and material compatibility. Striking a balance between performance and cost is critical for establishing a cost-effective 3D printing infrastructure. Thorough research and a forward-looking approach guide prudent decision-making.

B. Maintenance and Repairs

Regular Maintenance

Proactive maintenance is the linchpin for optimal printer performance and longevity. Implementing regular checks and preventive measures not only reduces the likelihood of breakdowns but also minimizes the impact of unexpected repair costs.

Repair Costs

Unforeseen breakdowns are an inevitable aspect of any technology. Preparing for repair costs and establishing contingency plans can mitigate the financial impact of unexpected maintenance issues. This foresighted approach ensures operational continuity and financial stability.

C. Equipment Costs Analysis

Beyond the initial capital investment, ongoing equipment costs demand meticulous attention. Calculating the total cost of ownership throughout the lifespan of the printers provides a holistic perspective on the financial implications. This includes factoring in maintenance, potential upgrades, and evolving technology trends.

IV. Calculating Labor Costs

A. Skilled Labor Requirements

3D Modeling and Design Skills

Expertise in 3D modeling is a cornerstone skillset. Assessing the proficiency of your design team is crucial for ensuring the efficient utilization of time and resources. A skilled design team contributes not only to the quality of the end product but also to the overall cost-effectiveness of the process.

Printing Operation Skills

Operational proficiency in running 3D printers is equally paramount. Proper training and ongoing skill development are essential components in minimizing errors, optimizing production efficiency, and, consequently, controlling labor costs.

B. Employee Compensation

Hourly Rates or Salary Structure

Choosing between hourly rates and a salary structure requires careful consideration. Aligning compensation with industry standards while factoring in employee skill levels is pivotal. Striking the right balance ensures fair remuneration for employees while maintaining cost efficiency for the business.

Overtime and Bonuses

Contingency planning for overtime and bonuses is vital, especially during peak production times. This foresighted approach not only ensures employee motivation during demanding periods but also helps in managing and controlling unexpected labor costs.

C. Labor Costs Analysis

Regular evaluations of labor costs relative to productivity and output are indispensable. Striking the right balance between labor expenses and production efficiency is key to maintaining financial equilibrium. Continuous improvement initiatives and efficiency measures contribute to long-term cost-effectiveness.

V. Additional Cost Considerations

A. Utilities and Operating Expenses

Electricity, Gas, and Other Utilities

Understanding and optimizing utility consumption directly impact the bottom line. Implementing energy-efficient practices, monitoring consumption patterns, and investing in renewable energy sources contribute to substantial long-term cost savings.

Facility Expenses (Rent/Lease, Insurance)

Leasing costs and insurance constitute fixed overheads that should be factored into the overall cost structure. Negotiating favorable lease terms and insurance rates contributes to overall cost-effectiveness and financial stability.

B. Marketing and Distribution Costs

Promoting 3D printing services incurs marketing and distribution expenses. A strategic approach to selecting marketing channels and optimizing distribution networks is crucial for cost-effective outreach. A well-thought-out marketing strategy not only ensures visibility but also contributes to a positive return on investment.

C. Amortization of Fixed Assets

Amortizing fixed assets, including 3D printers, over their useful life is a standard accounting practice. This method distributes the cost over time, providing a more accurate representation of ongoing expenses. Properly accounting for the amortization of fixed assets ensures a realistic portrayal of the financial health of the business.

D. Additional Costs Analysis

Regularly reviewing and analyzing additional costs ensures a proactive approach to financial management. Adapting to industry changes, embracing cost-effective solutions, and fostering a culture of continuous improvement contribute to long-term sustainability. This comprehensive analysis of additional costs safeguards against unforeseen financial challenges and enhances overall financial resilience.

In conclusion, mastering the art of calculating 3D printing way manufacturing costs entails a meticulous examination of each component. This in-depth guide equips you with the knowledge and tools necessary to navigate the financial intricacies, fostering expertise, authority, and trust in your 3D printing venture.