High-Quality Plastic Mold Making Services for You

V1 plastic mold making and manufacturing services are the perfect solution for businesses looking to create high-quality, custom molds for their products. Our team of experienced professionals meet your exact specifications.

V1 Plastic Mold Making Service process

Our factory has a rigorous workflow. Each job is carried out one by one in accordance with the requirements to ensure that each product is qualified.

Product DFM

Mold Design

Material Prepare

CNC Machine

EDM Machine

Wire Cutting

Polishing

Mold Fitting

Mold Trail

Sample Inspection

Product Assembly

Product Packaging

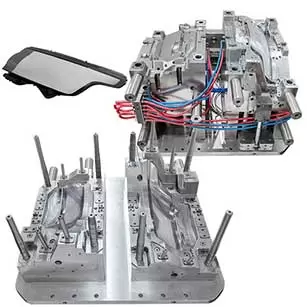

Plastic Injection Mold Services

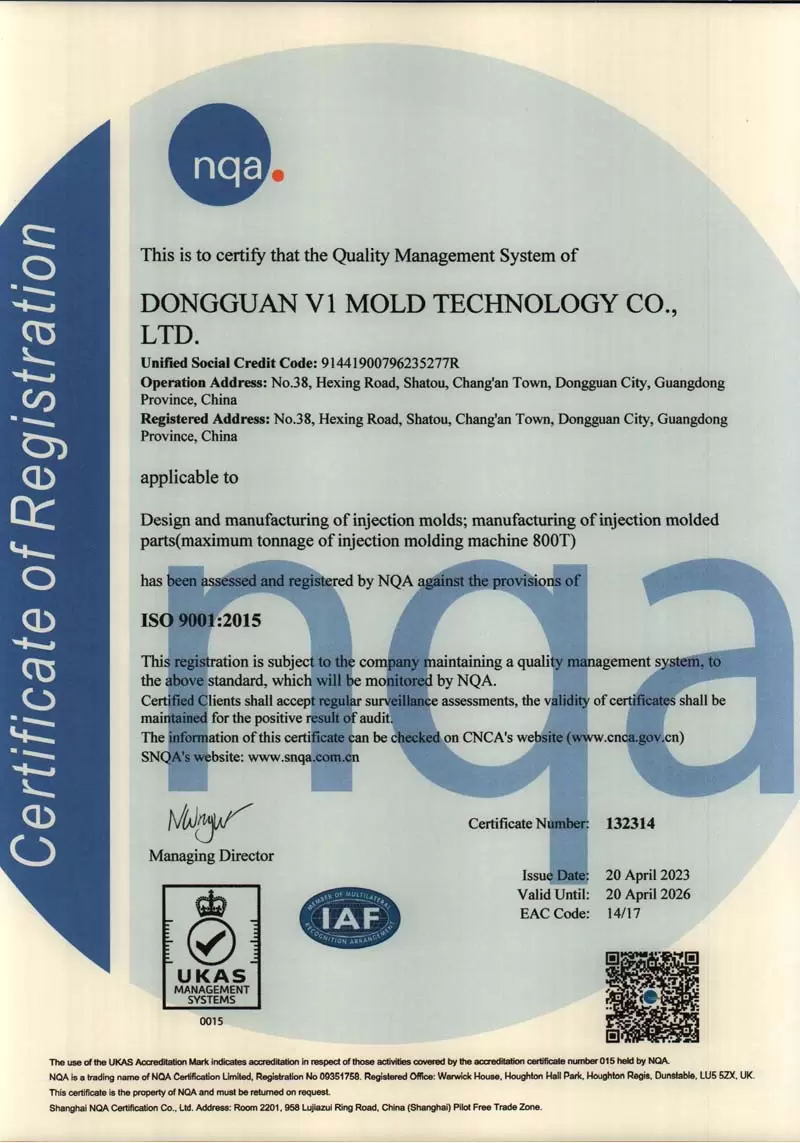

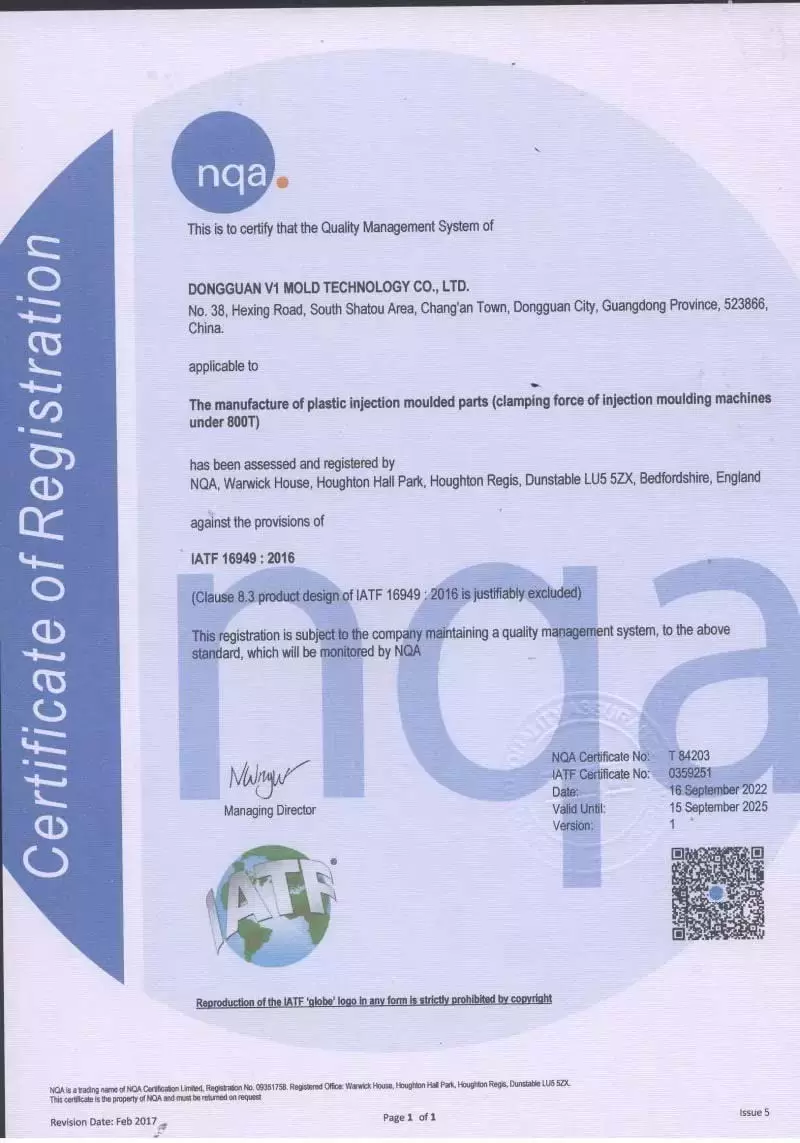

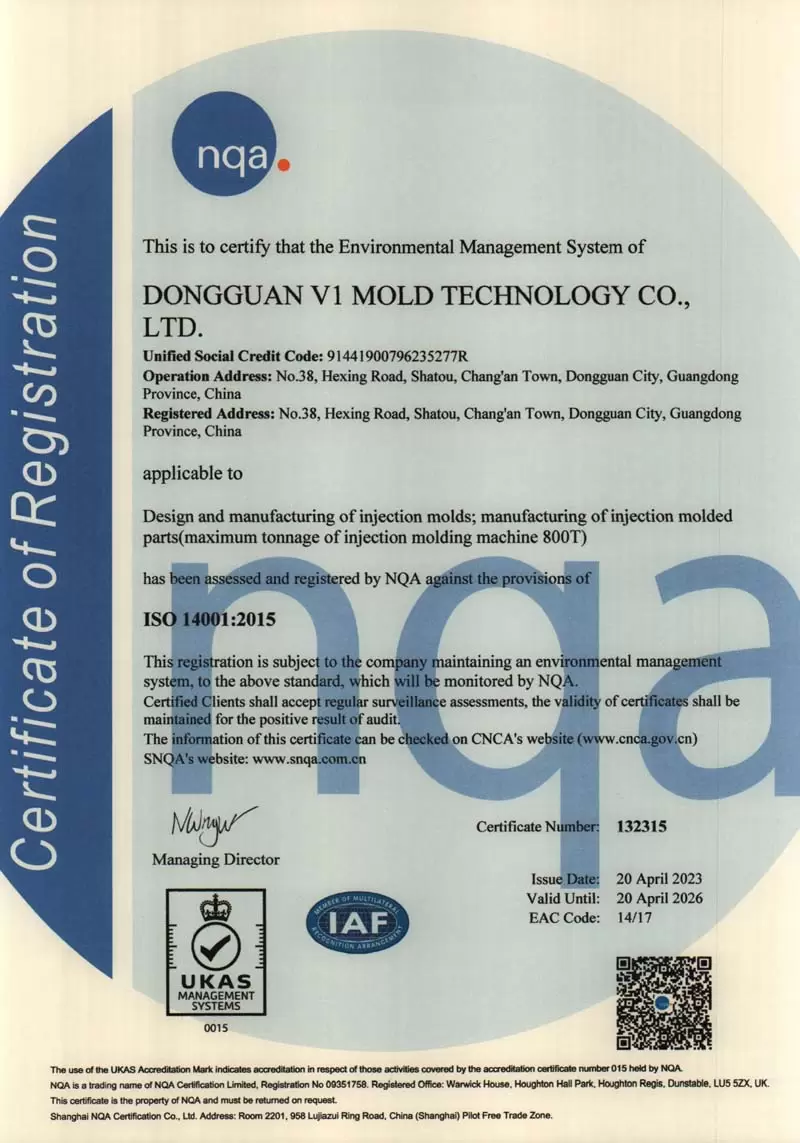

V1 has been designing and building plastic injection mould since 2006, using innovative design techniques, state-of-the-art technology, exceptional craftsmanship and advanced facilities to guarantee the high-quality molds and parts for our worldwide customers.

We offer a variety of tooling services including: Prototyping Mold, Multi-shot molds/2K molds and insert over-molding. Our customers are mainly in Automotive, Electronics, Appliance, Medical, Housewares industries.

With business expanding these years, we set up offices and overseas team in European and US countries such as UK, Germany, Slovakia, Mexico etc to continually meet or exceed our customers expectations and requirements.

V1 Mold Manufacturing and processing capacity

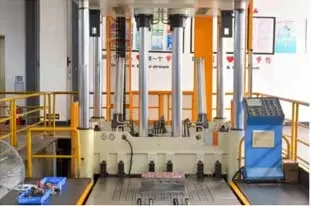

- 3 factories in China with advanced equipment including double-head EDM machines,mold fitting machine, large CNC machines etc.

- 20T-3500T injection molding machines to meet different customers needs.

- Maximum capable of making molds up to 35T.

- Over 30 overseas coworkers across the globe to provide our powerful local support from pre-sales communication, technical support to after-sales-service to further guarantee the high quality of molds and parts.

- Value-added service and resonable price.

Why Choose V1 Plastic Mold Service

Professional Team

V1 mold design & engineering team has 36 skilled engineers to provide technical support for plastic mold making and plastic processing.

17+ Years Experience

V1 mould has been manufacturing plastic tools for automotive, medical device and electronics for over 17 years.

One-Stop Solution

V1 offer a one-stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

Global After-sales Service

V1 responsible for the quality of each mold, will sign mold quality warranty with customers for every tools.

Advanced Equipment

V1 factory is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

V1 schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Our Plastic Mold partners

With our rich experience of toolmaking, powerful local support from our overseas teams and reasonable price, we have established long term win-win business cooperation with worldwide well-know companies.

Plastic Injection Mould FAQs

A plastic injection mold is a tool used to produce plastic parts through the injection molding process. The mold is typically made from metal and is designed to shape the molten plastic material into a specific form.

In the world of plastic injection molds, there are many different types. These types include, but are not limited to, single-cavity molds, multi-cavity molds, hot runner molds, cold runner molds, two-plate molds, three-plate molds, stacked molds, and family molds. Each mold has its own unique design and features to meet a variety of production needs.

First, let's look at the single-cavity mold. This kind of mold has only one cavity and is suitable for producing a single product. Its design is simple and its manufacturing cost is relatively low, but its production efficiency is correspondingly low.

Next comes the multi-cavity mold. Compared with single-cavity molds, multi-cavity molds have multiple cavities and can produce multiple identical products at the same time. The production efficiency of this kind of mold is high, but the manufacturing cost is also relatively high.

Let’s talk about hot runner molds and cold runner molds. In the hot runner mold, during the injection process, the plastic melt directly enters the mold cavity through the heated runner. In cold runner molds, during the injection process, the plastic melt enters the mold cavity through the cooled runner. The designs of these two molds have their own advantages and disadvantages, and they need to be selected according to specific production needs.

As for double-plate molds and three-plate molds, their main difference lies in the structure of the mold. A two-plate mold consists of two plates, while a three-plate mold consists of three plates. This design can improve the strength and stability of the mold, but it also increases manufacturing costs.

A stack mold is a complex mold type that consists of multiple plates stacked on top of each other to produce complex product shapes. This kind of mold is difficult to manufacture, but it can meet some special production needs.

Finally, we come to the family mold. This kind of mold is composed of multiple identical or similar parts and can produce a series of related products. The design of the family mold is flexible and can be combined and adjusted as needed, making it ideal for mass production.

In the manufacturing process, single-cavity molds and multi-cavity molds are two common mold types. The main difference between these two molds is the number of parts they can produce per cycle.

First, let's take a look at the single-cavity mold. A single-cavity mold is a mold that can only produce one part. That is to say, each time the mold completes a cycle, that is, the entire process from filling material, cooling, opening the mold, removing the finished product to filling material again, it can only produce one part. The advantage of this kind of mold is that it is simple to operate and only needs one operation to get a finished product. However, since only one part can be produced at a time, its production efficiency is relatively low.

Next, let’s take a look at multi-cavity molds. A multi-cavity mold is a mold that can produce multiple identical parts in a single cycle. This is because there are multiple independent cavities inside the multi-cavity mold, and each cavity can be filled, cooled, opened and removed from the finished product independently. Therefore, multiple identical parts can be produced simultaneously each time the mold completes a cycle. The advantage of this kind of mold is high production efficiency, which can greatly increase production speed. However, since each cavity requires independent operations, its operation complexity is relatively high.

In general, single-cavity molds and multi-cavity molds each have their own advantages and disadvantages, and the appropriate mold type needs to be selected based on specific production needs.

The service life of a plastic injection mold depends on a variety of factors including, but not limited to, the materials used to make the mold, the complexity of the mold design, and the quality of mold maintenance. With proper care and maintenance, a well-made mold can last for years or even decades.

First, let’s explore the impact of the materials used to make the mold on the life of the mold. Different materials have different properties and durability, so choosing the right one for a specific application is crucial. For example, some plastic materials may be more resistant to wear and tear, while others may be better suited to withstand high temperatures or pressures. Therefore, when selecting materials, the specific working conditions and environment the mold will be subjected to must be taken into consideration.

Secondly, the complexity of the mold design will also affect its service life. Complex mold designs may require more machining and assembly steps, which may increase the risk of mold failure during use. In addition, complex designs can make molds difficult to clean and maintain, further reducing their service life. Therefore, when designing the mold, the design should be simplified as much as possible to reduce unnecessary complexity.

Finally, the maintenance quality of the mold is also one of the key factors that determine its service life. Regular cleaning and inspection can help identify and promptly repair potential problems, thereby extending the life of the mold. In addition, proper lubrication and maintenance can also reduce mold wear and damage. Therefore, regular maintenance and upkeep are essential for any plastic injection mold.

To sum up, the service life of plastic injection molds is a complex issue and is affected by many factors. However, by choosing the right materials, simplifying the design, and performing regular maintenance and upkeep, we can maximize the life of the mold and ensure it performs optimally during production.

In order to keep the plastic injection mold in good condition, ensure its normal operation and extend its service life, we need to take a series of measures to maintain and maintain it. First of all, it is very important to keep the mold clean. During use, impurities such as dust and oil may accumulate on the surface of the mold. These impurities will affect the accuracy and performance of the mold. Therefore, we need to clean the mold regularly to remove dirt and impurities on the surface.

Secondly, lubrication is the key to ensuring the normal operation of the mold. During the injection molding process, the mold needs to withstand high temperature, high pressure and friction, which can cause mold wear and damage. In order to reduce wear, we need to apply lubricating oil to the mold regularly to reduce the friction coefficient, reduce wear, and extend the service life of the mold.

In addition, we also need to check whether the mold is damaged. During the use of molds, problems such as cracks and deformation may occur. These problems may cause the mold to not work properly or even cause production accidents. Therefore, we need to inspect the mold after each use and repair or replace it in time if any problems are found.

In order to achieve the above goals, we can develop a detailed mold maintenance plan. This plan should include cleaning, lubrication, inspection and maintenance. We can determine the specific operation methods and cycles of each link based on the actual situation. By executing this plan, we can ensure that the mold is always in good working condition and provides reliable guarantee for production.

It is true that a damaged plastic injection mold can be repaired, but the extent of repair will depend on the severity of the damage. Minor repair work, such as repairing scratches or chips, can often be done in-house, while more serious damage may require professional restoration services.

First of all, we need to make it clear that plastic injection molds may suffer various forms of damage during the production process, which may include surface scratches, fragments, or internal structural damage. These damages may affect the performance of the mold and may even cause the mold to fail to function properly.

Fortunately, however, these damaged plastic injection molds are not beyond repair. In fact, with the proper restoration measures, it is possible to restore these damaged molds to something close to their original condition.

However, it is important to note that the degree of mold repair is not set in stone and will vary depending on the severity of the mold damage. For minor damage, such as scratches or chips on the surface, we can repair it in-house. This repair is usually simple and only requires the use of some specialized tools and materials.

For some more serious damage, such as structural damage within the mold, we may need to seek professional repair services. This is because this type of damage is often complex and requires specialized knowledge and skills to repair effectively. Therefore, if the mold has suffered this type of damage, we usually recommend that customers seek professional repair services.

In general, although damage to plastic injection molds may cause some trouble in production, there are many ways to repair it. As long as we choose the appropriate repair method based on the severity of the mold damage, it is possible to restore the mold to something close to its original state.

Plastic injection molds are usually made of metals, including steel and aluminum. The decision to select a material depends on the needs of the specific mold, including expected service life, complexity of the design, and the type of plastic used.

When making plastic injection molds, metal materials such as steel or aluminum are often chosen. This is because these metals have excellent strength and durability and are able to withstand high temperatures and high pressure working environments. In addition, they have good thermal conductivity and corrosion resistance, allowing the mold to maintain its shape and dimensional stability during use.

However, choosing which material to make a mold from is not a simple matter. It needs to be comprehensively considered based on specific mold requirements. First, expected service life is an important factor. If the mold needs to withstand prolonged use and frequent cycles, it would be more appropriate to choose a material with a longer lifespan. Secondly, the complexity of mold design also needs to be considered. Complex designs may require greater precision and stability, so it will be more important to choose a material that provides better surface quality and greater precision. Finally, the type of plastic used is also a factor in material selection. Different types of plastics may have different requirements for mold materials. For example, some plastics may require better wear resistance and corrosion resistance.

To sum up, the material selection for plastic injection molds is a comprehensive decision-making process. It needs to take into account the expected life of the mold, the complexity of the design, and the type of plastic used. By rationally selecting materials, you can ensure that the mold can perform optimally during the production process, improving production efficiency and product quality.

When making plastic injection molds, the lead time required varies based on design complexity, mold size, and material availability. Generally speaking, this preparation time can range from a few weeks to a few months.

First, we need to consider the complexity of the design. If the design of the mold is very complex, more time may be required during the manufacturing process to ensure that all details are accurately replicated. This may involve a more complex computer-aided design (CAD) process, with more iterations and revisions. Therefore, design complexity is an important factor affecting manufacturing time.

Secondly, the size of the mold will also affect the manufacturing time. Large molds take longer to manufacture because they are larger, require more materials and a more complex production process. Additionally, large molds may require larger equipment for production, which also increases manufacturing time.

Finally, material availability also affects manufacturing time. This can increase manufacturing time if the required materials are in short supply or need to be transported from a distance. Additionally, if the materials used require special handling or processing, this may also increase manufacturing time.

Overall, the manufacturing time for plastic injection molds can range from a few weeks to a few months, depending on the complexity of the design, the size of the mold, and the availability of materials.

The cost of making a plastic injection mold depends on a variety of factors including, but not limited to, the size and complexity of the mold, the materials used to make the mold, and the number of cavities in the mold. Generally speaking, this cost can range from a few thousand dollars to tens of thousands of dollars.

The first thing we need to consider is the size and complexity of the mold. If the size of the mold is larger, or the design requires more details and complex structures, the time and materials required to manufacture such a mold will increase accordingly, thus increasing the cost. In addition, the complexity of the mold will also affect its manufacturing cost. For example, if a mold needs to have multiple parts or components, or requires special surface treatments or heat treatments, these additional processes and materials will increase manufacturing costs.

Secondly, the material used to make the mold is also an important factor affecting the cost. Different materials have different price and performance characteristics. Some common mold materials include metals such as steel, aluminum, and copper, as well as some specialty plastics or composite materials. Choosing high-quality materials ensures durability and accuracy of the mold, but it also increases costs. Therefore, there is a trade-off between cost and performance when determining mold materials.

Finally, the number of cavities in the mold is also a key factor affecting cost. Cavities refer to the individual cavities or grooves in the mold used to form the product. If there are more cavities in the mold, more time is needed to machine and assemble these cavities during the manufacturing process, thereby increasing the manufacturing cost. In addition, the design and layout of the cavity will also affect the complexity and manufacturing difficulty of the mold, thereby affecting the cost.

To sum up, the cost of manufacturing a plastic injection mold is a complex issue that is affected by many factors. Generally speaking, this cost can vary from a few thousand dollars to tens of thousands of dollars. Therefore, when formulating manufacturing plans and budgets, these factors need to be fully considered and reasonable cost estimates and controls made.

During the plastic injection molding process, the most common problem is the occurrence of defects in the molded parts, such as warpage, sink marks, and flash. These issues may have a negative impact on the quality and appearance of the product and require appropriate measures to be taken to resolve them.

First, we need to understand why these defects develop. In the plastic injection molding process, molten plastic is injected into a mold and then cools and solidifies into the desired shape. However, defects may occur in molded parts due to the influence of various factors such as temperature, pressure, material properties, etc.

Among them, warpage is the most common defect. It is usually caused by uneven mold temperatures or insufficient cooling time. As the plastic cools in the mold, it shrinks and creates stresses that, if not properly relieved, can lead to warping. To solve this problem, we can adjust the temperature distribution of the mold to ensure that the entire mold is cooled evenly, or extend the cooling time to give the plastic enough time to relieve stress.

Another common problem is sink marks, also known as dents or blowholes. It is usually caused by the plastic not filling completely when filling the mold or by the presence of air trapped in the material. To solve this problem, we can optimize the injection speed and pressure to ensure that the plastic fully fills the mold and avoids air being trapped in the material. In addition, appropriate release agents can be used to reduce the occurrence of sink marks.

Finally, flash is also a common defect. It is caused by the parting line of the mold not being clear enough or the injection speed being too fast. When the plastic separates from the mold, excess material is created, forming flash. In order to solve this problem, we can optimize the design of the mold to ensure that the parting line is clearly visible, and control the injection speed to avoid flashing caused by too fast injection.

To summarize, defects that may occur during the plastic injection molding process include warpage, sink marks, and flash. By understanding the causes of these defects and taking appropriate measures to solve them, we can improve the quality and appearance of the product and ensure that the final molded parts meet the requirements.

In order to prevent the occurrence of flash in plastic injection molds, we need to balance the injection molding process by adjusting the temperature, pressure and speed of the injection molding machine. This is a crucial step because if these parameters are not properly controlled, it can result in uneven thickness on the surface of the product and thus sparkle.

First, we need to accurately control the temperature of the injection molding machine. Temperature has a direct impact on the fluidity of plastics. If the temperature is too high, the plastic will flow too much, which may cause uneven thickness on the surface of the product, resulting in sparkle. On the contrary, if the temperature is too low, the fluidity of the plastic will be reduced, which may cause uneven thickness on the surface of the product and also produce flash. Therefore, we need to adjust the temperature of the injection molding machine to a suitable range based on the characteristics of the plastic and the needs of the product.

Secondly, we also need to accurately control the pressure of the injection molding machine. Pressure has a direct impact on the filling speed and filling effect of plastic. If the pressure is too high, the plastic may fill the mold too quickly, resulting in uneven thickness and flash on the surface of the product. On the contrary, if the pressure is too small, the filling speed and filling effect of the plastic may be affected, and it may also cause uneven thickness on the surface of the product and produce flash. Therefore, we need to adjust the pressure of the injection molding machine to a suitable range based on the characteristics of the plastic and the needs of the product.

Finally, we also need precise control over the speed of the injection molding machine. Speed has a direct impact on the filling speed and filling effect of plastic. If the speed is too fast, the plastic may fill the mold too quickly, causing uneven thickness on the surface of the product and causing flash. On the contrary, if the speed is too slow, the filling speed and filling effect of the plastic may be affected, and it may also cause uneven thickness on the surface of the product and produce flash. Therefore, we need to adjust the speed of the injection molding machine to a suitable range based on the characteristics of the plastic and the needs of the product.

In addition to adjusting the injection molding process, we can also prevent flash by using well-designed molds. A good mold should have a proper ventilation system, which can help us expel excess gas and moisture during the injection molding process, thereby reducing the generation of flash. In addition, the design of the mold should also take into account the structure and shape of the product to ensure that the surface of the product is smooth and uniform without flash.

Common question in Plastic Mold Production

The advantage of using a hot runner mold is that it can significantly reduce the generation of scrap materials, shorten the production cycle, and improve the quality of the parts. First of all, the design of the hot runner mold greatly reduces waste materials during the production process. This is because the hot runner mold can accurately control the flow of plastic melt, thereby avoiding unnecessary waste. Secondly, because the hot runner mold can quickly inject plastic melt into the mold, the production cycle is greatly shortened. This not only improves production efficiency, but also reduces production costs. Finally, because the hot runner mold provides uniform plastic melt flow, the quality of the parts produced is significantly improved. Overall, using hot runner molds has many advantages, including reducing scrap material, shortening production cycles, and improving part quality.

In the process of using hot runner molds, there are some shortcomings that cannot be ignored. First of all, the cost of this kind of mold is relatively high. Due to its complex design and manufacturing process, as well as the high-quality materials used, the price of hot runner molds is usually higher than that of traditional molds.

Secondly, the complexity of the hot runner mold also increases the difficulty of use. The design and operation of such molds require specialized knowledge and skills, and therefore some difficulties may be encountered by inexperienced operators. In addition, due to its complex structure, if a problem occurs, it may require professional technicians to repair it, which undoubtedly increases the difficulty of use.

Finally, hot runner molds have higher maintenance requirements. Due to its complex structure and materials used, this mold requires regular maintenance and inspections to ensure its proper functioning. Not only does this require more time and resources to be invested, but if not properly maintained, it may cause the mold to degrade in performance or even malfunction.

Overall, while hot runner molds offer many advantages in the injection molding process, their high cost, complex operation and maintenance requirements are also important factors to consider.

The advantages of using cold runner molds are mainly reflected in the following aspects: First, it can significantly reduce production costs. Since the design and manufacturing process of cold runner molds are relatively simple, their manufacturing costs and maintenance costs are relatively low. Secondly, the design of the cold runner mold is simpler and clearer, which makes its installation and debugging during the production process more convenient, thus improving production efficiency. Finally, since cold runner molds suffer less wear during use, the frequency of maintenance and replacement is also relatively low, which undoubtedly further reduces production costs. In general, the use of cold runner molds can not only reduce production costs, but also simplify the design process and reduce maintenance requirements, thereby bringing greater economic benefits to the enterprise.

When discussing the disadvantages of using cold runner molds, there are several key factors to consider. First, a major disadvantage of this type of mold is its long production cycle time. Because cold runner molds take longer to cool and solidify the plastic material, the time required for the entire production process increases accordingly. This may lead to a decrease in production efficiency, thereby affecting the company's production plans and delivery times.

Secondly, the use of cold runner molds will also lead to an increase in scrap materials. Since cold runner molds will produce more waste and leftover materials during the production process, these waste materials need to be cleaned and processed, thus increasing production costs. In addition, the disposal of these waste materials may also have a certain impact on the environment, so companies need to take corresponding measures during the production process to reduce the generation and disposal of waste materials.

Finally, using cold runner molds may also reduce part quality. Since the cold runner mold may produce some uneven cooling effects during the production process, some defects and blemishes may appear in the plastic material during the molding process. These defects can affect the strength, durability and cosmetic quality of the part, thereby reducing the overall quality of the product.

In summary, although cold runner molds can provide some advantages in certain situations, there are also some disadvantages to their use. When companies decide whether to use cold runner molds, they need to comprehensively consider factors such as their production cycle, scrap materials, and part quality to make the most appropriate decision.

In mold manufacturing, we often encounter different types of molds, the most common of which are two-plate molds and three-plate molds. The main difference between these two molds is their structural design and how they are used.

First, let’s take a closer look at the two-plate mold. A two-plate mold is a very common mold type that consists of two main parts: a bottom plate and a top plate. The two parts are separated by a single parting line. When the injection molding process is complete, this parting line opens, allowing the two parts of the mold to separate. This separation process is called "mold splitting" and it is an important step in the mold manufacturing process. During this process, the two parts of the mold move in opposite directions, pushing the injection molded product out of the mold. This is called "demoulding." Therefore, we can say that the two-plate mold design makes the product demoulding process simpler and more efficient.

Next, let’s take a look at the three-plate mold. Compared with two-plate molds, the structure of three-plate molds is more complex. It includes not only a bottom plate and a top plate, but also a middle plate. This middle plate is independent of the bottom plate and the top plate, and it can be separated from the bottom plate or the top plate. This design allows the three-plate mold to have greater flexibility during the injection molding process. For example, when an injection-molded product needs to be removed from the mold, the middle plate can be separated from the bottom or top plate, making the demoulding process of the product easier. In addition, the three-plate mold can also be used to produce some complex products because it can provide larger cavity space.

In general, two-plate molds and three-plate molds each have their own advantages and disadvantages. The structure of the two-plate mold is relatively simple and the operation is relatively easy, but the demoulding process may be difficult. Although the three-plate mold has a more complex structure, its demoulding process is easier and can be used to produce more complex products. Therefore, when choosing a mold type, we need to consider it based on specific production needs and conditions.

Three-plate molds offer many advantages during the design and manufacture of complex parts. First, this mold offers greater design flexibility. This means that designers can adjust the shape and size of the mold as needed to suit a variety of different product needs. This flexibility enables the three-plate mold to cope with various complex design requirements, thereby greatly improving product quality and production efficiency.

Secondly, the manufacturing process of three-plate molds is also more flexible. Due to its unique structure, three-plate molds can be more easily modified and adjusted to meet changing production needs. This allows manufacturers to quickly optimize molds during production, thereby improving production efficiency and product quality.

In addition, three-plate molds offer greater durability. Due to their complex structure and precision design, three-plate molds are generally more durable than traditional two-plate molds and can maintain efficient operation for a longer period of time. This not only reduces the frequency of mold replacement and production costs, but also ensures product consistency and quality.

Overall, three-plate molds have significant advantages in designing and manufacturing complex parts. Its design flexibility, manufacturing flexibility and durability make it the first choice for many manufacturers.

In the plastic manufacturing industry, molds are vital tools. They are used to shape and form the shape and structure of plastic products. Molds can be divided into many types based on their design and functionality, the two most common of which are home molds and stacking molds.

First, let’s take a look at home mold. A family mold is a single mold that is capable of producing multiple different parts. This type of mold is often used to produce products that require parts of different shapes or sizes. By using home molds, manufacturers can produce many different products on the same machine, increasing production efficiency and flexibility.

In contrast, a stacked mold is a mold with multiple parting lines that can produce multiple identical parts in a cycle. This type of mold is often used to produce products that require large quantities of the same parts, such as automotive parts, appliance casings, etc. By using stacked molds, manufacturers can produce multiple identical parts simultaneously in one cycle, greatly increasing production efficiency and throughput.

In summary, both home molds and stacking molds are commonly used mold types in the plastic manufacturing industry. They each have unique designs and functions that can meet different types of product production needs. Whether producing multiple different parts or large quantities of the same parts, both molds provide manufacturers with efficient, flexible and economical solutions.

In manufacturing, a tool called a stack die has many advantages. First, a significant advantage of stacked molds is their ability to increase production efficiency. By using this mold, manufacturers can produce more products in a shorter period of time, thereby greatly improving overall production efficiency.

Secondly, another advantage of stacking molds is its ability to shorten production cycle times. Traditional molds may take a long time to complete the production process of a product, while stacking molds can greatly shorten the production cycle time by optimizing the production process and reducing unnecessary steps.

Finally, stacking molds also reduces material waste. Due to the nature of its design, stacking molds can utilize materials more efficiently, reducing material waste during production. This not only helps manufacturers save costs, but is also beneficial to the environment.

Overall, the advantages of stacking molds include increased production efficiency, shorter production cycle times, and reduced material waste. These advantages make stacked molds widely used in manufacturing.

When considering various mold types, the advantages of home molding cannot be ignored. First, the cost of home molds is relatively low. Home molds are much less expensive to make and maintain than other types of molds. This is because home molds are usually made using simpler materials and processes, so their production costs are lower. In addition, due to the smaller scale of home molds, their maintenance and repair costs are relatively low.

Second, home molds take less time to set up. The setup process for home molds is simpler and faster than other types of molds. This is because the design and manufacturing process of home molds are relatively simplified, so their setup time is greatly shortened. This is undoubtedly a huge advantage for companies that need to produce large quantities of products quickly.

Finally, home molds can improve production efficiency. Because the design and manufacturing process of home molds are relatively simplified, their production process is more efficient. This not only increases the production speed of products, but also reduces the error rate during the production process. In addition, because the maintenance and repair costs of home molds are relatively low, their service life is also relatively long, which also helps improve production efficiency.

Overall, home molding offers the advantages of low cost, short setup time, and high efficiency. These advantages make home molds widely used in many fields.

There are many factors to consider when deciding which plastic injection mold you should choose for your project. These factors include, but are not limited to, the complexity of the part design, the number of parts required, the materials used, and the desired production speed. Each of these factors can have a significant impact on the final choice.

First, part design complexity is an important consideration. If the part design is very complex, then more advanced or specialized molds may be needed to ensure the quality and accuracy of the part. On the other hand, if the part design is relatively simple, it may be possible to choose a more economical and practical mold.

Secondly, the number of parts required also affects mold selection. If you need to produce a large number of parts, you may want to choose a mold that can produce them efficiently. And if you only need to produce a small number of parts, you may be able to choose a mold that is less expensive and less efficient but still of reliable quality.

In addition, the materials used are also an important consideration. Different materials may require the use of different types of molds. For example, some special plastics may require the use of special molds to ensure their performance and quality.

Finally, the desired production speed is also an important consideration. If you want to produce quickly, you may want to choose a mold that can be produced quickly. And if there are no particularly high requirements for production speed, you may be able to choose a mold that is lower cost, slightly less efficient but still reliable in quality.

Therefore, choosing a suitable plastic injection mold is a complex process with many factors to consider. To ensure you make the best choice, it's helpful to work with an experienced mold designer or manufacturer. They can provide you with professional advice and solutions based on your needs and specific circumstances.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: info@v-1.com

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850