Table of Contents:

- Introduction

- The CNC Machining Process

- Advantages of China CNC Machining

- Choosing a China CNC Machining Provider

- Industries Served by China CNC Machining

- Future Trends in China CNC Machining

- Conclusion

-

1.Introduction

CNC (Computer Numerical Control) machining refers to the use of software-controlled machines to produce complex parts with high precision and consistency. The machines are programmed to follow specific instructions, which dictate the movements of the cutting tools and the creation of the final products.

CNC machining has a significant impact on global manufacturing, and China can now be considered a global leader in this industry. China’s CNC machining industry has undergone rapid and dramatic growth in the past few decades, and it is now one of the largest and most diverse in the world.

In the early days of CNC machining in China, the industry was primarily comprised of small workshops, which focused on low-cost machining services. However, with the growth of China’s economy and the increased demand for high-quality manufacturing, CNC machining has emerged as a critical sector within the country’s manufacturing landscape.

Today, China’s CNC machining industry includes everything from small, family-run shops to massive, state-of-the-art facilities that cater to domestic and international customers alike. The growth of this industry has been supported by a highly skilled workforce, a robust supply chain, and a deep commitment to innovation and technological advancement.

-

2.The CNC Machining Process

How CNC Machines Work:

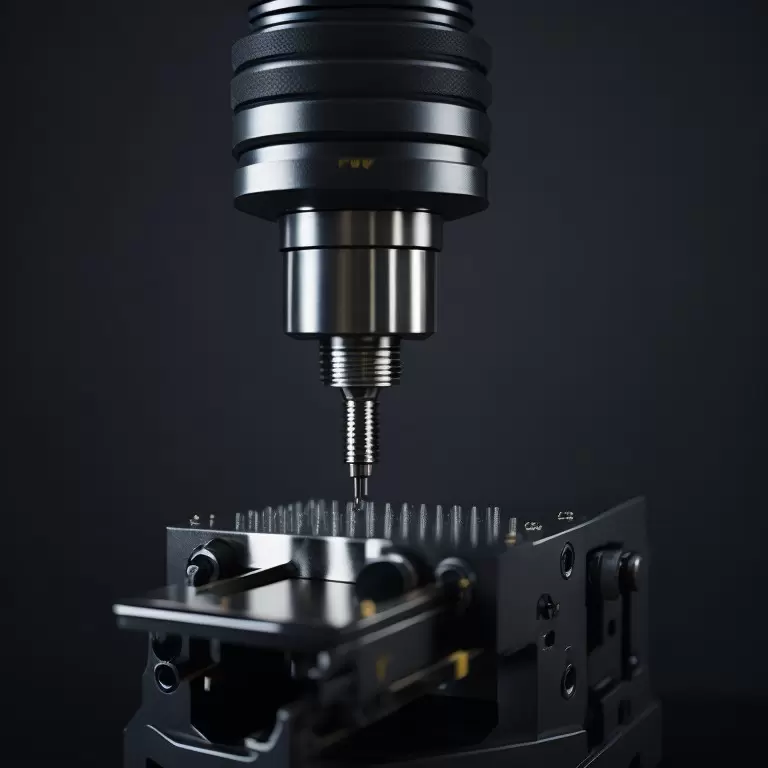

CNC machines work by following a pre-programmed set of instructions that dictate the movements of the cutting tools. These instructions are created using computer-aided design (CAD) software and then passed along to the CNC machine, which reads the instructions and interprets them as movements along x, y, and z axes. The machine has a cutting tool attached to a spindle, which rotates at high speed during the machining process.

Types of CNC Machines Used in China:

There are several types of CNC machines used in China, each with its unique advantages and capabilities. Some of the most commonly used include:

- CNC Milling Machines: These machines use rotary cutters to remove material from a stationary workpiece. They can produce a wide range of shapes, including flat and contoured surfaces, and are suitable for both small and large production runs.

- CNC Lathes: These machines rotate a workpiece on a spindle while a cutting tool shapes and cuts the material. They are ideal for producing cylindrical parts and are often used in high-volume production runs.

- CNC Routers: These machines use a spinning cutting tool to carve out complex shapes and patterns from materials such as metal, wood, and plastics. They are often used in the creation of furniture, signs, and other decorative objects.

- CNC Plasma Cutters: These machines use a high-energy plasma torch to cut through metal and other conductive materials. They are ideal for cutting intricate patterns and designs from sheet metal.

.

Materials Commonly Machined with CNC Machines:

CNC machines can work with a wide range of materials, including plastics, metals, and composites. Some of the most commonly machined materials include:

- Aluminum: CNC machining is a popular method for creating aluminum parts, which are lightweight, durable, and resistant to corrosion.

- Stainless Steel: Stainless steel is a hard, strong material that is used in a wide range of industries, including aerospace, automotive, and medical devices.

- Plastics: CNC machines can create parts from a variety of plastic materials, including PVC, nylon, and polycarbonate.

- Carbon Fiber: Carbon fiber is a strong, lightweight material that is used in high-performance applications such as aerospace and motorsports.

Overall, CNC machining has revolutionized the manufacturing industry in China, delivering high precision, accuracy, and efficiency to a wide range of products and applications.

-

3.Advantages of China CNC Machining

Cost-effectiveness:

One of the main advantages of CNC machining in China is its cost-effectiveness. By using CNC machines, manufacturers can produce large quantities of parts at a lower cost than manual machining. This is due to the fact that CNC machines can work continuously for long periods, reducing labor costs and minimizing the errors and waste associated with manual machining.

High Precision and Accuracy:

CNC machines are highly precise and can produce parts with very tight tolerances. The programmed instructions ensure that every movement of the cutting tool is consistent and accurate, resulting in parts that are identical in size, shape, and quality. This level of precision is particularly important in industries such as aerospace, automotive, and medical devices, where the highest quality and accuracy are essential.

Large-Scale Production Capabilities:

CNC machines are capable of producing large quantities of parts quickly and efficiently. This makes them ideal for high-volume production runs, where consistency and quality are key. CNC machines can also be programmed to run continuously and can be easily integrated into automated production lines, further increasing their production capacity.

Flexibility in Design and Customization:

CNC machines have the ability to work with a wide range of materials and can produce parts in complex shapes and designs. This allows for greater flexibility in design and customization and enables manufacturers to create parts that may not be possible with manual machining. CNC machines can also be reprogrammed quickly and easily, allowing for rapid changes in production and increased product customization.

Overall, the advantages of CNC machining in China have helped to establish the country as a world leader in manufacturing. The cost-effectiveness, precision, large-scale production capabilities, and flexibility in design and customization make CNC machining a valuable tool for a wide range of applications and industries.

-

4.Choosing a China CNC Machining Provider

Important Factors to Consider When Selecting a Provider:

When selecting a CNC machining provider in China, it’s important to consider several key factors, including their reputation, manufacturing capabilities, quality assurance practices, and customer service. It’s also important to consider their experience and expertise in producing parts for your specific industry, as this can help to ensure that they have the necessary equipment, skills, and knowledge to meet your production requirements.

Evaluating a Provider’s Experience, Expertise, and Quality Assurance Practices:

Before partnering with a CNC machining provider in China, it’s important to evaluate their experience, expertise, and quality assurance practices. This can include reviewing their portfolio of past projects, checking their references, and conducting an on-site inspection of their facilities. It’s also important to determine whether they have the necessary certifications and quality control procedures in place to ensure that every part is produced to the highest standards.

Comparing Costs and Production Timelines:

When selecting a CNC machining provider in China, it’s important to compare costs and production timelines among potential providers. This can include obtaining quotes from multiple providers, comparing their pricing structures, and determining whether they have the necessary capacity to meet your production needs. It’s also important to consider factors such as shipping costs, customs fees, and taxes when comparing costs among providers.

Best Practices for Partnering with a China CNC Machining Provider:

To ensure a successful partnership with a CNC machining provider in China, it’s important to establish clear communication channels, establish production timelines and quality expectations, and establish a mutual understanding of your specific design and manufacturing requirements. It’s also important to maintain an ongoing relationship with your provider, providing regular feedback and updates on production and quality issues, and working collaboratively to identify areas for improvement and innovation.

Overall, selecting the right CNC machining provider in China requires careful evaluation and consideration of several key factors, including reputation, experience, quality assurance practices, cost, and production capabilities. By taking the time to carefully evaluate potential providers and establish a strong working relationship, manufacturers can leverage the expertise and production capabilities of China’s CNC machining industry to meet their production needs and achieve their business goals.

If you need about CNC Machining Services,You can click on the V1 Prototype website to find it.

-

5.Industries Served by China CNC Machining

Automotive:

The automotive industry is a major user of CNC machining services in China. CNC machines are used to produce a wide range of automotive parts and components, including engine parts, transmission parts, and suspension parts. With their ability to produce high volumes of parts with tight tolerances and precise specifications, CNC machines are critical to the production of high-quality automotive parts.

Aerospace:

The aerospace industry is another major user of CNC machining services in China. CNC machines are used to produce a wide range of aerospace components, including aircraft engine parts, structural components, and landing gear. With their ability to produce highly complex parts with extreme precision, CNC machines are essential to the aerospace industry.

Medical Devices:

The medical device industry in China relies heavily on CNC machining services for the production of a wide range of medical devices, including implants, surgical tools, and diagnostic equipment. CNC machines can produce highly complex medical devices with the necessary precision and accuracy required for medical applications.

Consumer Electronics:

The consumer electronics industry in China also relies heavily on CNC machining services. CNC machines are used to produce a wide range of electronic components, including casings, connectors, and circuit boards. With their high precision and fast production capabilities, CNC machines are critical to the production of high-quality consumer electronics.

Industrial Equipment and Manufacturing:

CNC machining services are also critical to the industrial equipment and manufacturing industries in China. CNC machines are used to produce a wide range of industrial equipment and components, including machine tools, molds, and dies. With their ability to produce highly accurate, high-quality parts, CNC machines are essential to the efficient and cost-effective production of industrial equipment.

Other Industries:

CNC machining services in China are also used in other industries, including energy, agriculture, construction, and defense. CNC machines can be used to produce a wide range of parts and components in these industries, providing high precision, accuracy, and efficiency to a wide range of applications.

Overall, CNC machining services in China serve a diverse range of industries, providing high-quality parts and components for a wide range of applications. With their precision, accuracy, and scalable production capabilities, CNC machines are critical to the success of many businesses and industries around the world.

-

6.Future Trends in China CNC Machining

Emerging Technologies and Advancements:

There are several emerging technologies and advancements in CNC machining that are likely to continue to shape the industry in China in the coming years. These include the increasing use of artificial intelligence (AI) and automation to improve production efficiency and quality; the adoption of Industry 4.0 technologies, such as the Internet of Things (IoT), cloud computing, and big data, to support more data-driven and interconnected manufacturing processes; and the increasing use of additive manufacturing, such as 3D printing, in conjunction with CNC machining to create complex and highly customized parts.

Growth Projections and Market Outlook:

The future outlook for the CNC machining market in China is positive, with continued growth projected in the coming years. This growth is being driven by several key factors, including the expansion of manufacturing activities and the increasing adoption of advanced technologies. According to a recent report by Grand View Research, the global CNC machining market is projected to reach $100.9 billion by 2027, with China expected to be one of the fastest-growing regions in the industry.

Environmental and Sustainability Initiatives:

Environmental and sustainability initiatives are likely to have an increasing impact on the CNC machining industry in China in the future. With concerns about climate change and carbon emissions increasing, manufacturers are under increasing pressure to reduce their environmental footprint and adopt more sustainable practices. This is likely to drive the development of new technologies and processes that minimize waste and energy consumption while improving efficiency and production quality. Additionally, initiatives around the circular economy, which aims to reduce waste and increase the reuse and recycling of materials, are likely to have an increasing impact on the CNC machining industry in China in the coming years.

-

7.Conclusion

In summary, CNC machining has revolutionized the manufacturing industry in China by providing high precision, accuracy, and efficiency to the production process. Some of the key points to note include the cost-effectiveness, high precision, large-scale production capabilities, and flexibility in design and customization that CNC machining offers. Additionally, CNC machines are used in a wide range of industries, including automotive, aerospace, medical devices, consumer electronics, industrial equipment, and more.

Looking towards the future, emerging technologies like AI, Industry 4.0, and additive manufacturing, coupled with strong growth projections and the increasing emphasis on sustainability, are set to drive the continued growth and innovation of CNC machining in China.

Overall, CNC machining in China has proven to be a valuable tool for manufacturers looking to produce high-quality parts quickly and efficiently. With its many benefits and diverse applications, CNC machining is set to play an increasingly critical role in the manufacturing industry in China and around the world.