3D printed hand plates may need to be printed in disassembly when the design of the hand plate is complex or larger than the build volume of the 3D printer. Printing in disassembly refers to breaking down the 3D model of the hand plate into multiple smaller parts or components that can be printed separately and then assembled together to form the complete hand plate. This approach allows for the creation of larger and more intricate designs that may not fit within the limitations of a single 3D print.

Here are some scenarios where 3D printed hand plates may be printed in disassembly:

1. Size Limitations:

If the hand plate design is large and exceeds the maximum build volume of the 3D printer, it becomes necessary to divide the model into smaller parts that can be printed separately. Once all the individual parts are printed, they can be assembled to create the final hand plate.

2. Complex Geometries:

Hand plates with intricate and complex geometries may require support structures for successful 3D printing. Printing such designs in disassembly allows for better orientation of each part to minimize the need for supports, leading to better print quality and reduced post-processing.

3. Functionality and Articulation:

Some hand plate designs may require movable or articulating parts for enhanced functionality. Printing in disassembly allows for the creation of separate components that can later be assembled with hinges, pins, or other connectors to achieve the desired range of motion.

4. Multi-Material Printing:

Certain hand plate designs may involve the use of multiple materials to achieve specific properties or characteristics. Printing in disassembly allows for the use of different materials for different components, enabling the creation of hybrid hand plates with varied properties.

5. Aesthetics and Surface Finish:

In cases where hand plates require a flawless surface finish or intricate details, printing in disassembly can help reduce the risk of surface defects caused by support structures. Each part can be printed with optimal settings for surface quality, and the assembly process ensures a seamless and polished final product.

6. Prototype Iterations:

When developing hand plates with multiple design iterations, printing in disassembly can be beneficial. It allows for easier modification of specific components without the need to reprint the entire hand plate, saving time and material.

7. Material Constraints:

Certain 3D printing materials have limitations in terms of mechanical properties or printability. Printing in disassembly allows for the use of specific materials for each part based on their functional requirements.

Conclusion

Printing 3D hand plates in disassembly is a practical approach when dealing with complex designs, size limitations, or the need for functional and aesthetic enhancements. This method allows designers and engineers to overcome the constraints of 3D printing technology and create more sophisticated and customized hand plate designs that fulfill specific requirements for functionality, aesthetics, and performance. By carefully planning the disassembly and assembly process, 3D printed hand plates can be successfully fabricated and assembled into fully functional and visually appealing end products.

As the name implies, a disassembled model is a model that is originally a whole hand-made board that needs to be taken apart and printed in pieces and then finally assembled.

Can't 3D printing be done in one piece? Why do you need to print in pieces?

In fact, not, even 3D printing also need to take apart the printing time, the following we analyze together need to take apart the three cases of printing.

01、The model is too big

3D printers have a print size that can withstand, if you want to print a large model, because the volume is too large, 3D printers can not print such a large model at once, it is necessary to separate to play.

In fact, whether it is 3D printing or CNC machine processing in the processing time have size restrictions, which is limited by the size of the machine, it is impossible to machine only 1 m, but to process 2 m hand board model, which can not be processed.

There are also different 3D printing materials, the maximum size of a single piece of 3D printing model is also different.

02、Special structure can not meet the requirements

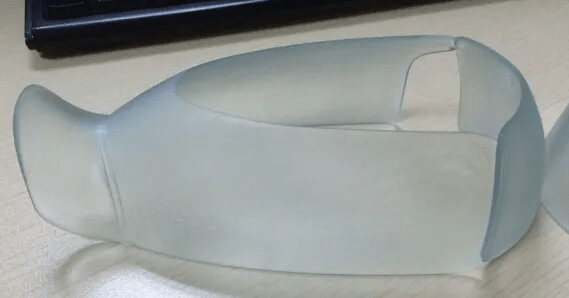

There are also some special structure can not meet the requirements, such as the following figure of glasses, is the frame and legs are printed separately, because one print, then the frame and leg interface is combined, can not be flexible rotation, thus failing to verify the use of this glasses hand plate model.

Of course the glasses hand plate is printed in one piece, and yes, devices like this that require flexible rotation can also be designed and eventually 3D printed. The example given here is just for reference.

Another example is the 3D printing of transparent photosensitive resin, transparent photosensitive resin needs to be polished, if some parts can not be polished, it will affect the transparency, this time you can dismantle the print, polished after dismantling, and then glued, the choice of shadowless glue sticky words, sticky parts of transparency or quite good.

03、Dismantling may be cheaper

For example, a CNC model with a height of 650mm, a length of 600 and a maximum side width of 300mm. If the whole model were to be CNC machined, it would have to be made from ABS, which is 650mm high, 600mm long and 300mm wide, but in reality, this model does not need that much material and it would probably take less than a fifth of the material needed to make the whole model.

3D printing is rarely cheaper in the printable range, because 3D printing is additive manufacturing, in addition to the necessary support materials, the rest is the material used to print the model, and 3D printing does not exist in the complex structure of the model processing more expensive situation.

About the disassembly printing, you can do a good job of communicating with customer service in a timely manner, to tell customer service the requirements, so that 3D printing out of the hand model to get the hands to be satisfied, not to affect the use.