Table of Contents:

- Introduction

- Advantages of Injection Moulding

- Key Similarities Between Injection Moulding and Other Processes

- Understanding the Differences in Injection Moulding and die casting

- Applications of Injection Moulding

- Conclusion

-

1.Introduction

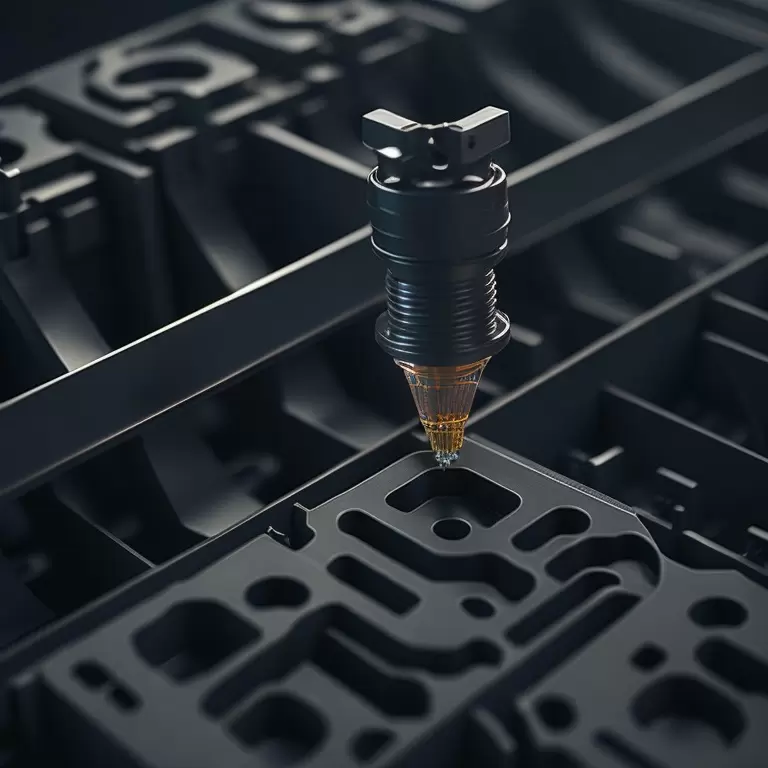

Injection moulding is a manufacturing process that involves injecting molten material, usually thermoplastic or thermosetting polymers, into a mould cavity under high pressure. The material is heated to a liquid state and injected into the mould, where it cools and solidifies, taking the shape of the mould cavity. The mould is then opened, and the solidified part or product is ejected, ready for further processing or assembly. Injection moulding is typically used for large-scale production of parts with complex shapes, high precision, and tight tolerances.

-

2.Advantages of Injection Moulding

Injection moulding offers several advantages that make it a preferred manufacturing process in various industries. Some of the key advantages of injection moulding are:

- High Production Speed: Injection moulding is a high-speed manufacturing process that allows for the production of a large volume of parts or products in a relatively short amount of time. The use of automated machines, precise mould design, and optimized process parameters ensures efficient and continuous production, resulting in higher productivity and shorter lead times.

- Precision and Repeatability: Injection moulding offers high precision and repeatability, allowing for the production of parts with consistent dimensions, tight tolerances, and intricate details. The use of computer-controlled machines, precise mould design, and process monitoring ensures consistent quality and performance of the produced parts, making it suitable for applications that require high precision and reliability.

- Design Flexibility: Injection moulding provides immense design flexibility, allowing for the production of parts with complex shapes, varying wall thicknesses, and integrated features. This enables designers to create innovative and functional parts that may not be feasible with other manufacturing processes. Injection moulding also allows for the use of inserts, overmoulding, and multi-cavity moulds, further expanding the design possibilities.

- Material Selection: Injection moulding supports a wide range of materials, including various thermoplastic and thermosetting polymers, composites, elastomers, and metals. This provides manufacturers with the flexibility to choose the most suitable material for their specific application, considering factors such as strength, durability, chemical resistance, and aesthetics. Injection moulding also allows for material recycling and reusability, making it environmentally friendly.

- Cost-effective: Injection moulding can be a cost-effective manufacturing process for high-volume production. The high efficiency of the process, minimal material waste, and reduced labor costs contribute to its cost-effectiveness. Injection moulding also eliminates the need for additional processing steps for complex parts, reducing overall production costs.

- Scalability: Injection moulding is a scalable process that can accommodate small to large production volumes. The use of automated machines allows for efficient production of high volumes, while the flexibility in mould design and material selection makes it suitable for small-batch production as well. This scalability makes injection moulding adaptable to the changing production demands of various industries.

- Consistency and Quality: Injection moulding offers consistent quality and performance of the produced parts due to the precise control of process parameters and the use of automated machines. This ensures that each part is virtually identical, meeting the required specifications and standards. Injection moulding also minimizes the occurrence of defects, such as porosity, voids, and inconsistencies, resulting in high-quality finished products.

- Reduced Waste: Injection moulding generates minimal material waste compared to other manufacturing processes, as the excess material can be recycled and reused. This reduces the overall material costs and minimizes the environmental impact of the manufacturing process.

- Automation and Efficiency: Injection moulding can be fully automated, reducing the dependence on manual labor and improving the overall efficiency of the manufacturing process. Automated machines allow for precise control of process parameters, consistent production, and reduced cycle times, resulting in higher productivity and cost savings.

-

3.Key Similarities Between Injection Moulding and Other Processes

While injection moulding has unique advantages, it also shares some key similarities with other manufacturing processes. Understanding these similarities can help in better understanding the capabilities and limitations of injection moulding. Some of the key similarities between injection moulding and other processes are:

- Material Heating: Like many other manufacturing processes, injection moulding involves heating the material to a molten state before it is injected into the mould cavity. This allows the material to flow and take the shape of the mould, resulting in the desired part or product. Material heating is a crucial step in various manufacturing processes, including extrusion, blow moulding, and some casting processes, where the material needs to be melted or softened before shaping.

- Mould Design: The design of the mould is a critical aspect of injection moulding, as it determines the final shape, dimensions, and features of the part or product. Similarly, in other manufacturing processes such as casting, forging, and stamping, the design of the die or mould plays a crucial role in shaping the material. Mould or die design involves considerations such as material flow, cooling, and ejection, to ensure the production of high-quality parts.

- Precision and Tolerance: Injection moulding, along with other manufacturing processes, requires precision and tolerance considerations to ensure that the final parts meet the desired specifications. In processes like machining, casting, and forming, precision and tolerance play a crucial role in achieving the desired part dimensions and functionality. These considerations are critical in ensuring that the parts fit and function correctly in the final assembly.

- Material Selection: Just like in injection moulding, material selection is a vital aspect of other manufacturing processes as well. Material selection depends on factors such as the application requirements, part functionality, environmental conditions, and cost considerations. In processes such as casting, forging, and stamping, the selection of the appropriate material is essential to achieve the desired part properties, including strength, durability, and performance.

- Process Optimization: Process optimization is a common aspect of most manufacturing processes, including injection moulding. Optimization involves fine-tuning process parameters, such as temperature, pressure, cycle time, and cooling, to achieve the best possible results in terms of part quality, productivity, and cost-effectiveness. Process optimization is crucial in ensuring efficient and consistent production in various manufacturing processes.

- Quality Control: Quality control is a critical aspect of manufacturing, and it is common to injection moulding as well as other processes. Injection moulding, like other processes, requires inspection and testing of the produced parts to ensure that they meet the required specifications and standards. Quality control involves various techniques such as dimensional inspection, material testing, and functional testing, to ensure that the parts are of high quality and meet the intended purpose.

- Environmental Impact: Injection moulding, like many other manufacturing processes, has an environmental impact due to factors such as material waste, energy consumption, and emissions. Similarly, other processes such as casting, machining, and forming also have environmental implications. Manufacturers need to be aware of the environmental impact of various processes and take steps to minimize it through measures such as recycling, waste reduction, and energy-efficient practices.

Injection moulding shares some key similarities with other manufacturing processes, including material heating, mould design, precision and tolerance considerations, material selection, process optimization, quality control, and environmental impact. Understanding these similarities can help manufacturers better understand the capabilities and limitations of injection moulding and make informed decisions in selecting the most appropriate manufacturing process for their specific requirements. By leveraging the similarities and unique advantages of injection moulding and other processes, manufacturers can achieve efficient, high-quality, and sustainable production of parts and products.

-

4.Understanding the Differences in Injection Moulding and die casting

Injection molding and die casting are both highly effective manufacturing methods that have revolutionized modern manufacturing. While they share some similarities, there are a number of significant differences between the two processes. In this article, we will discuss the differences between injection molding and die casting.

Injection molding is a process of manufacturing plastic components by injecting molten plastic material into a mold under high pressure. The process is highly effective for the production of complex, high-precision parts, and can be used to manufacture a wide range of parts, from large automotive components to small electronic devices. Injection molding is highly versatile, and can be used to produce parts with a wide range of shapes, sizes, and textures.

Die casting, on the other hand, is a process of manufacturing metal components by forcing molten metal into a mold under high pressure. It is a highly efficient manufacturing process that is ideal for producing high-volume, complex parts with excellent surface finish and dimensional accuracy. Die casting can be used to produce a wide range of parts, including components for automotive, aerospace, and medical applications.

One of the main differences between injection molding and die casting is the materials used in each process. Injection molding is typically used to produce plastic parts, while die casting is used to produce metal parts. This difference in materials has a significant impact on the manufacturing process, as the two materials have different properties and require different production techniques.

Another key difference between injection molding and die casting is the speed of production. Injection molding is a fast process that can produce large volumes of parts in a short amount of time, making it ideal for mass production. Die casting is also a fast process, but it is typically used for smaller production runs, as the cost of tooling can be prohibitively expensive for larger production runs.

Finally, there is a difference in cost between the two processes. Injection molding is typically less expensive than die casting, as the tooling costs are lower and the production process is simpler. However, die casting can be more cost-effective for certain applications, as it can produce parts with higher precision and better surface finish.

In conclusion, injection molding and die casting are two highly effective manufacturing processes that have different applications and different strengths. Injection molding is ideal for producing plastic parts quickly and cost-effectively, while die casting is ideal for producing metal parts with high precision and excellent surface finish. Depending on the specific requirements of a project, either process may be the best choice.

If you need about Injection Moulding Services,You can click on the V1 Prototype website to find it.

-

5.Applications of Injection Moulding

Injection moulding is a popular manufacturing process that is used to produce a wide range of plastic products, parts and components. This method has revolutionized the production of plastic products since it offers an efficient and cost-effective way to mass-produce high-volume parts quickly and accurately. Here are some of the most common applications of injection moulding:

- Automotive industry - Injection moulding is widely used in the automotive industry to produce a variety of components, including dashboards, seats, panels, bumper covers and many more. These parts require high strength, durability, and precision and injection moulding offers the perfect solution.

- Consumer products - Injection moulding is used extensively to manufacture consumer products such as toys, kitchenware, office equipment, and electronic devices. This method allows manufacturers to create complex shapes with high precision using a variety of materials, including thermoplastics and thermosetting plastics.

- Medical devices - Injection moulding is widely used in the medical industry to produce a diverse range of medical devices, including syringes, vials, catheters, and other disposable medical products. The process ensures that the products are sterile, durable, and safe to use.

- Packaging industry - Injection moulding is used extensively in the packa ging industry to produce plastic bottles, caps, containers, and other packaging materials. These products are highly durable and offer excellent protection against external factors like moisture, dust, and light.

- Aerospace industry - The aerospace industry uses injection moulding to manufacture a variety of components used in aircraft, including cockpit controls, structural components, and engine parts. Injection moulding allows for the precise manufacturing of parts, which is critical in the aerospace industry.

- Electrical industry - Injection moulding is used to manufacture electric components such as switches, enclosures, connectors, and housings. This method ensures that the components produced are durable, precise, and of high quality.

In conclusion, injection moulding has a wide range of applications across various industries, thanks to its versatility, precision, and cost-effectiveness. Manufacturers have exploited the benefits of this innovative process to develop a wide range of products that meet the needs of the market..

-

6.Conclusion

In conclusion, injection moulding is a highly versatile and efficient manufacturing process that has revolutionized the production of plastic products, parts, and components. The process enables manufacturers to produce high-quality parts with precision, while reducing production costs and minimizing waste. Injection moulding is widely used across a diverse range of industries, including the automotive, consumer products, medical, packaging, aerospace, and electrical industries, among others. With its ability to produce complex shapes, high volumes, and a wide range of materials, injection moulding is an essential tool for manufacturers seeking to increase productivity, reduce lead times, and improve product quality. Ultimately, injection moulding has become a key driver in the shift towards sustainable manufacturing practices, enabling manufacturers to produce products that are eco-friendly, efficient, and cost-effective.