Table of Contents:

- Introduction

- Factors Affecting Plastic Molding Prices

- How Plastic Molding Prices are Calculated

- Plastic Molding Price Examples

- Ways to Reduce Plastic Molding Costs

- Conclusion

-

1. Introduction

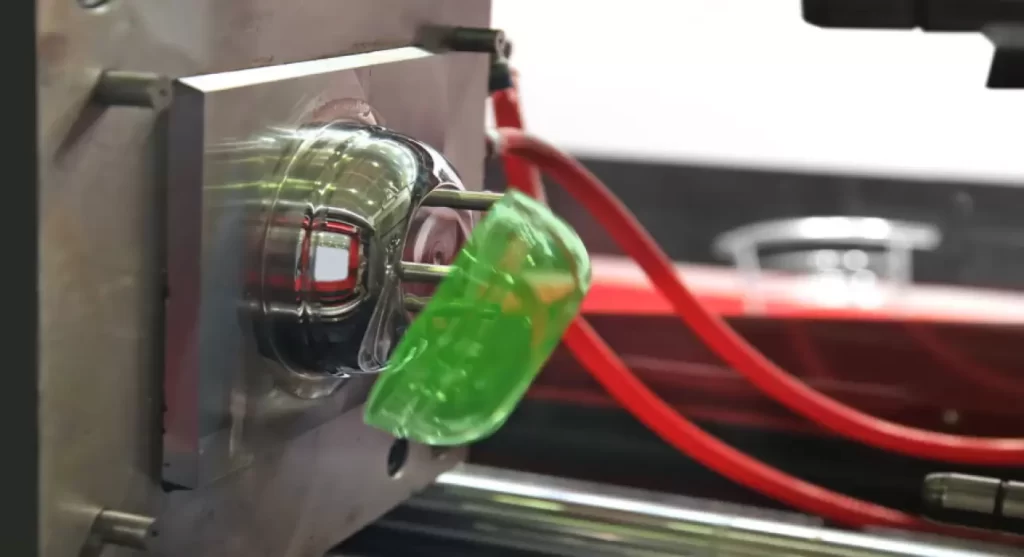

Plastic molding is a popular manufacturing process used to create custom plastic parts for various industries. From small medical device components to large automotive parts, plastic molding enables manufacturers to produce parts with complex geometries and precise dimensions. However, the cost of plastic molding can vary significantly depending on several factors. In this article, we will discuss the factors that affect plastic molding prices, how plastic molding prices are calculated, examples of plastic molding costs, and ways to reduce plastic molding costs.

-

2. Factors Affecting Plastic Molding Prices

Several factors can impact the cost of plastic molding, including the type and quality of material, complexity of part design, production volume, manufacturing location, and tooling costs.

- Type and Quality of Material: The type and quality of material used for plastic molding can significantly impact the cost. Some materials are more expensive than others, such as high-performance polymers or specialty grades. Additionally, the quality of the material can also affect the cost. High-quality, pure resins will cost more than those with fillers or recycled content.

- Complexity of Part Design: The complexity of the part design can also impact plastic molding prices. The more complex the design, the more time and effort it will take to manufacture the part. This can include features such as undercuts, threads, or intricate shapes.

- Production Volume: The production volume also affects the cost of plastic molding. High volume production typically lowers the unit price, while low volume production can increase the cost per part. Tooling costs can also impact this factor.

- Manufacturing Location: The cost of plastic molding can vary depending on where the production facility is located. For instance, labor and overhead costs in an overseas facility may be lower than those in the United States.

- Tooling Costs: Tooling refers to the molds and equipment used for the plastic molding process. The initial investment for tooling can be significant, but it also impacts the cost per part. High-quality tooling typically results in lower per-part costs over the long term.

-

3. How Plastic Molding Prices are Calculated

Plastic molding prices are typically calculated based on a cost breakdown, which includes material, labor, overhead, and profit. Understanding the cost breakdown can help manufacturers estimate the cost of their plastic molding needs accurately.

The cost breakdown for plastic molding includes the following:

- Material Cost: The cost of the material used for plastic molding, which includes the resin or plastic, additives, colorants, and any other necessary components.

- Labor Cost: The cost of labor required to manufacture the plastic part, including machine setup time, cycle time, and operator time.

- Overhead Cost: The overhead cost includes all the indirect expenses associated with the manufacturing process, including rent, utilities, maintenance, and other facility costs.

- Profit: A margin of profit will be included in the overall cost.

-

4. Plastic Molding Price Examples

To better understand plastic molding prices, let’s look at some examples.

- Case Studies: Low Volume vs High Volume Production

Low volume production typically results in a higher cost per part. For example, if you want to produce 500 parts using injection molding, the cost per part may range from $5 to $20. However, if you want to produce 10,000 parts, the cost per part may range from $1 to $10, depending on the complexity of the part. - Comparing Domestic vs Overseas Molding Costs

Manufacturing in overseas facilities may result in lower labor costs, but it can also result in longer lead times, shipping costs, and quality control issues. Domestic manufacturing may be more expensive, but it often provides better quality control and shorter lead times.

-

5. Ways to Reduce Plastic Molding Costs

Several strategies can be used to reduce the cost of plastic molding, including the following:

- Design for Cost Savings: The part design can be modified to simplify it, reduce the material required, or to eliminate any features that may add to the cost.

- Material Selection: Choosing the right material can help reduce the overall cost of plastic molding. Standard materials may be less expensive than high-performance ones.

- Production Efficiency: Optimizing the production process can help reduce the overall cost of plastic molding. This can include automation, reducing scrap, or reducing machine downtime.

-

6. Conclusion

Understanding the factors that affect plastics molding prices, how they are calculated, and strategies to reduce the costs, can help manufacturers estimate and reduce the cost of plastic molding to produce high-quality parts. Working with a trusted plastic molding partner can also help ensure consistency, quality, and reliable lead times in the manufacturing process.

If you want more about Plastic Molding information ,You can click on the V1 Prototype website to find it.