Introduction to Rapid Tooling

Rapid Tooling, also known as rapid tooling manufacturing or RTM, is a subset of rapid prototyping technology that focuses on the rapid fabrication of tooling molds or dies used for mass production. It bridges the gap between rapid prototyping and traditional manufacturing processes by providing a fast and cost-effective method for producing high-quality molds and tooling. Rapid tooling allows manufacturers to streamline their production process, reducing lead times and costs while maintaining precision and quality.

Types of Rapid Tooling

There are several techniques used in rapid tooling, each suited for different applications and production requirements. Some common types of rapid tooling include:

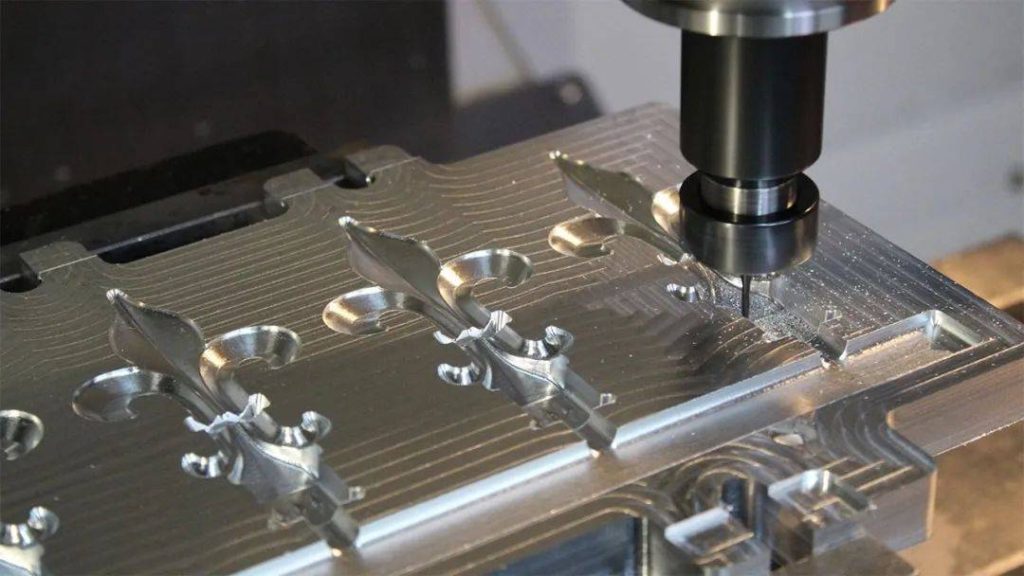

- CNC Machined Tooling: This method involves the use of Computer Numerical Control (CNC) machines to fabricate molds and tooling from metal or plastic blocks. It offers high accuracy and is suitable for small to medium production runs.

- Soft Tooling (Silicone Molding): Soft tooling employs silicone molds to create a limited number of parts. While not as durable as metal tooling, it is quicker and more cost-effective for low-volume production.

- 3D Printed Tooling: Additive manufacturing technologies like 3D printing can be utilized to create molds and tooling, especially for complex geometries and rapid iterations.

- Investment Casting Tooling: This technique involves creating patterns with rapid prototyping methods, which are then used to make investment molds for casting.

Advantages of Rapid Tooling

- Reduced Lead Times: Rapid tooling significantly reduces the time needed to manufacture tooling molds compared to traditional methods. This leads to faster production start-up and quicker time-to-market for new products.

- Cost-Efficient Prototyping: For low-volume production or prototyping, rapid tooling eliminates the high costs associated with traditional tooling methods, making it a more economical choice.

- Complex Geometries: 3D printing and other rapid tooling techniques enable the production of complex geometries that would be challenging or impossible with traditional tooling methods.

- Iterative Design: Rapid tooling allows for faster design iterations, enabling manufacturers to test and improve product designs efficiently.

- Customization and Personalization: With rapid tooling, it is easier and more cost-effective to produce custom or personalized products, catering to individual customer needs.

- Flexibility in Materials: Rapid tooling supports various materials, including metals, plastics, and composites, offering flexibility in choosing the best material for the specific application.

- Improved Quality Control: Rapid tooling processes, such as CNC machining, ensure high precision and consistency, resulting in better quality finished products.

Production Speed

The production speed in rapid tooling varies depending on the chosen technique and the complexity of the mold or tooling required. Generally, rapid tooling offers significantly faster production times compared to traditional tooling methods.

For example, CNC machined tooling can produce molds within a matter of days, while 3D printed tooling can be fabricated in a few hours to a few days, depending on the size and complexity of the mold. Soft tooling can be even quicker, with molds made from silicone within hours.

It is important to note that rapid tooling is most beneficial for low to medium production volumes. For very high volume production, traditional tooling methods might still be more suitable, considering the initial investment can be offset by the mass production's economies of scale.

Conclusion

Rapid tooling has emerged as a game-changer in modern manufacturing, offering accelerated production, reduced costs, and increased design flexibility. By leveraging the advantages of rapid tooling, manufacturers can bring products to market faster, efficiently test new designs, and stay ahead in today's competitive business landscape. As 3D printing and other rapid prototyping technologies continue to advance, rapid tooling will play an increasingly crucial role in shaping the future of production and innovation across various industries.

Mold for industry is a mainstream and conventional manufacturing technology, rapid mold, as the name suggests that is the production of mold time is short, faster than conventional mold production to more than 1.5 times. Both are molds, rapid mold why so fast? Our industrialists have years of experience in manufacturing various kinds of rapid tooling. For example, we have stock sizes for our rapid tooling, so that the tooling can be shared without duplicating production and processing work, and only fine-tuning can be done. Our industrial people's rapid die rarely use automatic inserts and sliders, basically they use manual operation. Quick mold customer itself to the mass production requirements are not high, in the production is not high, manual instead of intelligent automation, will be more advantageous. Of course there are more quick tips and details when making quick molds, and there will be more detailed process breakdown for customer's drawings.

Quick mold why is called quick mold

Moulds have a wide range and involve a wide range of industries, moulds can be called the mother of industrial manufacturing, and it can even be said that there is no new product without moulds. Today we will talk about the rapid steel die within the mold range, also called soft die.

Fast steel mold itself is not the mainstream of industrial manufacturing process, many manufacturing professionals are not very clear what fast mold is and its use, the industry called different, fast mold, fast soft mold, fast steel mold, fast aluminum mold, etc. are its name. Called different, in fact, the demand is similar, that is "for fast".

The advantages of fast aluminum mold.

- Aluminum mold modeling production easy to modify (aluminum has good plasticity and processing properties)

- Fast time (aluminum processing fast)

- Aluminum materials ordered from stock (today's order can arrive tomorrow for processing)

- Mold can do texture, polishing

Disadvantages of fast aluminum mold.

- mold life between 1K-1W

- Mold injection production is not subject to pressure

Fast mold can play what role

Fast mold is generally used in the R&D trial stage, but also used in the production of various products with low output. The rapid die is sometimes also called a test die, before the mass production of products to make a set of rapid die to do experiments, out of the formal mold before the engineering structure verification. Rapid die is low cost, short time consuming, and can find its unreasonable in time before the formal mold production, so that the engineering research and development personnel can visually see the problem on the rapid die, and then make corrections to the mold product drawings to improve the service life of the formal mold.

What kind of products are suitable for quick mold

Plastic parts with output batches less than 5000 are very suitable to be finished by rapid mold. Low mold cost, short production time, fast transformation, the new era of product appearance change speed is unimaginable. For example, cell phones, cars, some products, consumers just bought not long before there are new products on the shelves. In the era of rapid change of consumer products, fast mold has a great role.

Do rapid mold production, choose Industrial Man rapid prototyping

Industrial Man has 20 years of accumulation of many kinds of rapid prototyping technology and tens of millions of new product development processing and production experience. Industrial Man has a strong team that can precisely interface with customers for one-to-one professional cooperation, especially in rapid mold with considerable professional ability as well as dedicated entrepreneurial spirit. With the advantages of our Industrial Man product production, quick and easy molds can be completed in as little as three days from mold design to mold production out of the finished product!