Harness the power of Selective Laser Melting technology with our cost-effective solutions. We offer reliable machines that can enhance your production processes and reduce manufacturing expenses.

Table of Contents:

I. What is Selective Laser Melting?

- Definition and Benefits of SLM Technology

II. Understanding Selective Laser Melting Machine Cost

- Factors Affecting Selective Laser Melting Machine Prices

- Comparing SLM Machine Costs to Traditional Manufacturing Methods

III. Affordable Selective Laser Melting Solutions

- Recommended Brands and Models

- Tips for Saving on SLM Machine Costs

IV. Enhancing Productivity with Selective Laser Melting

- Advantages of Using SLM Machines for Prototyping and Series Production

- Case Studies and Success Stories of SLM Implementation

V. Frequently Asked Questions about Selective Laser Melting Machines

- Common Inquiries from Customers about SLM Technology and Machine Costs

- Expert Answers and Practical Solutions for Common SLM Challenges.

I. What is Selective Laser Melting?

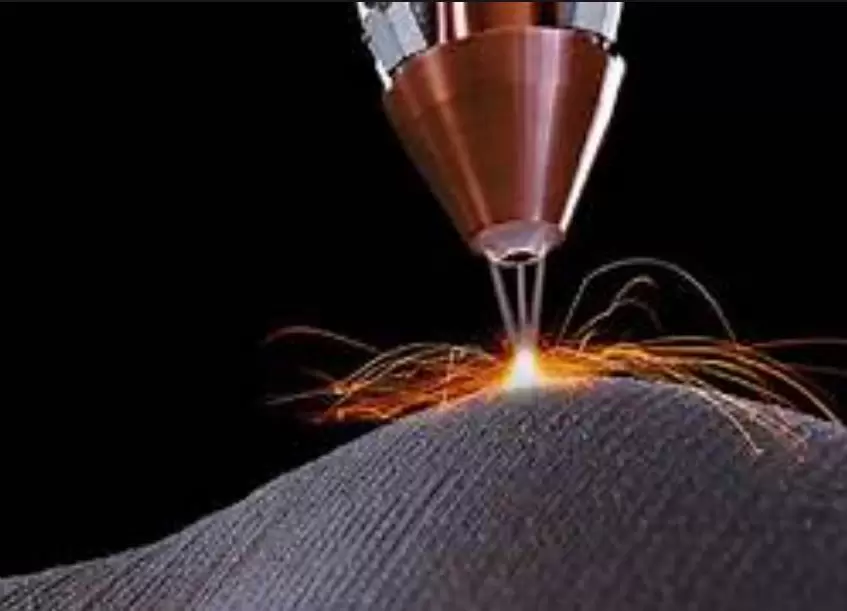

Selective Laser Melting (SLM) is a type of Powder Bed Fusion (PBF) Additive Manufacturing (AM) technology. It is a highly precise method of melting metal powder using a laser beam, which fuses and solidifies the metal particles layer by layer, creating a 3D object. SLM technology is particularly useful in creating complex geometries with internal structures that are difficult or impossible to achieve through traditional manufacturing processes.

SLM technology offers a plethora of benefits over conventional technologies. First and foremost, SLM is capable of producing intricate geometries, lightweight structures, and optimized designs that not only increase the performance of the components but also require less material. Additionally, SLM machine can operate in a wide digital environment, allowing it to reduce lead times and costs involved with tooling, making integrated and automated systems much simpler.

II. Understanding Selective Laser Melting Machine Cost

Selective Laser Melting machines are costly and generally out of the budget for small to mid-sized companies to purchase outright. Investing in the technology requires a well-thought-out strategy and careful consideration of several factors. Here are some of the main factors affecting Selective Laser Melting Machine cost:

- Machine Capability: The machine’s ability to produce complex designs and materials creates a range of cost points. Higher-end SLM machines with additional features and advanced functionalities are the most expensive.

- Size of the Printing Bed: The size of the printing bed is directly proportional to the cost. Depending on the requirement, larger bed size may be necessary which will normally more expensive.

- Laser Power: The higher the laser power, the more expensive the machine. Higher laser power is required to print certain materials or to print certain geometries faster.

- Material Specification: Different materials require different machine specifications, which impact the pricing.

- Machine Maintenance: Like all equipment, SLM machines need routine maintenance. The software system, equipment upgrades, and spare parts compatibility may impact routine maintenance.

- Regulatory Approvals: Complying with safety and regulatory requirements adds to the production costs.

- Service and Support: The provider’s inclusion of training, installation, servicing, and support can add to the overall cost.

Comparing SLM Machine Costs to Traditional Manufacturing Methods

The same parts that are manufactured using SLM technology can be manufactured using other conventional traditional methods. The main difference is how the parts are produced. For instance, parts produced via CNC machining require excess material and material removal steps.

CNC machines cut and shape parts from larger pieces of metal or other materials manually, whereas SLM machines use lasers to sinter together layers of a powdered material. Machining is an excellent option for several applications, but SLM involves less material waste and increased production efficiency.

However, even taking into account the lower production cost for SLM printing, the cost of materials remains higher than traditional manufacturing methods, and the process can take longer than alternatives like injection molding or die casting for larger production runs.

III. Affordable Selective Laser Melting Solutions

SLM machines can be costly, but the benefits of the technology make the investment worth it in the right circumstance. Companies can minimize Selective Laser Melting machine’s cost by selecting the right machine that fulfills their needs from seemingly endless designs and systems. By looking at machine specifications thoroughly and selecting a machine fulfilling the current and future capabilities, they can get the maximum in return.

When it comes to purchasing SLM machines, the expertise and guidance of an industry professional can prove useful. Here are some affordable, quality, and reliable Selective Laser Melting machines worth considering:

- SLM 280: A mid-size bed machine with a high-quality build, consistent, and accurate printing, the SLM 280 is the most popular among among the SLM family. It is priced relatively lower compared to other SLM machines.

- SLM 500: One of the largest bed sizes available, the SLM 500 is excellent for larger production runs. This machine is designed for users who require high-quality parts in large quantities. The machine is priced on the higher end of the SLM machine range, but its cost is justified by its large bed size and the ability to create a wide range of complex geometries.

- Concept Laser X LINE 2000R: Another large bed size machine, the X LINE 2000R is a heavy-duty system ideal for high-volume production. It can produce large and complex geometries, making it suitable for aerospace and medical applications. This machine may be slightly more expensive than some of the other SLM machines, but its large bed size and high-end capabilities justify the cost.

- Renishaw AM 400: Another popular mid-size machine, the AM 400, is simple to use and is ideal for those new to SLM technology. The machine is ideal for prototyping, and small batch work is a cost-effective and reliable option since it can be purchased at a lower price point than some of the other machines on the market.

- EOSINT M 280: The EOSINT M 280 is a machine that rivals the SLM 280. While they share many of the same features, the EOSINT M 280 is available at a lower cost. The machine is perfect for small to mid-sized companies who are looking to enter the world of SLM technology without breaking the bank.

- Tips for Saving on SLM Machine Costs

- Purchase Used Machinery: Purchasing used machinery can be an excellent way to save costs. You will need to research the machine’s condition and maintenance history, but if you find a reliable and well-maintained machine, you do not have to spend too much money.

- Consider Leasing: Leasing a Selective Laser Melting machine is an alternative option for those wanting to use the technology without committing to a full purchase. Leasing has advantages as upgrades and maintenance are covered by the lease, and it also frees up the company’s cashflow for other necessary expenses.

- Join a SLM Membership Group: By signing up for a membership group such as SLM Solutions’ Service and Support Program, companies can benefit from reduced costs for repairs, spare parts, and upgrades.

IV. Enhancing Productivity with Selective Laser Melting

- Advantages of Using SLM Machines for Prototyping and Series Production

- Selective Laser Melting technology provides advantages over traditional manufacturing technologies, and all these benefits lead to increased productivity. Here are some of the benefits that SLM technology brings to the table:

- Enhanced Design Freedom: SLM technology’s design flexibility and intricate qualities allow creativity in design, resulting in parts that can perform more efficiently and effectively.

- Speed: SLM machines can print complex designs at a rapid pace, thereby reducing lead times. This benefit allows for quick design iteration without the need for more costly tooling.

- Lightweighting: Selecting the right material for a part and optimally designing it using SLM can reduce weight by up to 70%.

- Low Waste: SLM technology generates less waste and scrap, which eventually leads to lower production costs.

- Reduced Manufacturing Costs: SLM technology can reduce the costs involved in manufacturing due to less material use, no tooling, and shorter lead times.

- Customization: SLM can also create unique designs for one-off or prototype components, making them ideal for low-volume and high-value productions.

- Case Studies and Success Stories of SLM Implementation

- SLM has been successfully implemented across a wide range of industries and applications:

- Rolls-Royce: Rolls-Royce uses SLM to create complex designs for turbine blades that operate at high temperatures and stresses while minimizing weight.

- Airbus: Airbus harnesses the flexibility of SLM technology to manufacture lightweight designs low-volume engines.

- Medical Devices: By utilizing SLM technology, companies are creating customized medical implants for patients with specific bodily requirements.

V. Frequently Asked Questions about Selective Laser Melting Machines

- Common Inquiries from Customers about SLM Technology and Machine Costs

- What materials can be used in an SLM machine?

- SLM machines most commonly use metal powders, including aluminum, titanium, steel, and cobalt-chrome. However, some machines can work with polymers and plastic materials.

- What is the typical lead time for printing parts on an SLM machine?

- The lead time for printing parts is dependent on the complexity of the part. However, SLM machines are widely known for their speed, with parts typically taking a few hours to print.

- What is the advantage of cylinder surface milling using SLM technology?

- Cylinder surface milling is a process that can produce significantly higher quality and highly accurate parts, making the entire operation more precise.

- What is the minimum purchase price for a Selective Laser Melting Machine?

- The cost of SLM machines varies widely based on factors such as size, laser power, and capabilities. They range from $100,000 to over $1 million, depending on the machine’s size and advanced features.

- Can SLM machines work with composite materials?

SLM machines are primarily designed for metals and metal alloys but can work with composite materials under certain conditions.

- How often should an SLM machine undergo maintenance?

SLM machines require regular maintenance, including regular cleaning, calibration, and replacement of parts. The frequency of maintenance depends on the usage and factors like machine model, material usage, and environmental conditions.

Expert Answers and Practical Solutions for Common SLM Challenges

- Quality control issues are prevalent in SLM technology, requiring a skilled and trained operator to manage the machine.

The best approach is to have an experienced SLM operator on staff to oversee the printing process. Companies can also invest in comprehensive training programs to ensure the operators have the knowledge and skills required to navigate quality control challenges.

- The production speed can be a challenge with SLM technology.

To overcome this challenge, companies can invest in machines with higher laser power, finer powder particles dimensions, and operating temperatures. They can also optimize designs to reduce printing time without compromising quality.

- Limited build volume might be insufficient for larger components leading to designs being split into smaller components and printed individually, requiring subsequent assembly.

To mitigate this challenge, companies can invest in machines with larger build volumes, utilize advanced software solutions to optimize designs, and redesign or optimize parts to allow for more efficient printing and assembly.

In conclusion, Selective Laser Melting machines provide distinct advantages over traditional manufacturing processes. They are perfect for creating complex geometries, optimizing designs, producing lightweight structures, and increasing efficiency in prototyping and series production. Affordability and availability should not be a hurdle for companies as there are different acquisition options, enabling cost-effective SLM machine solutions.