Discover the significant role of lasers in additive manufacturing and explore how this cutting-edge technology is revolutionizing the manufacturing industry. This comprehensive article provides insights into the various aspects of using lasers for additive manufacturing, including its principles, advantages, applications, and challenges. Gain a deeper understanding of how lasers are shaping the future of manufacturing.

Table of Contents:

- Introduction

- Understanding Additive Manufacturing

- The Role of Lasers in Additive Manufacturing

- 3.1 Principles of Laser-based Additive Manufacturing

- 3.2 Laser Sources for Additive Manufacturing

- Advantages of Laser-based Additive Manufacturing

- 4.1 High Precision and Accuracy

- 4.2 Versatility in Materials and Applications

- 4.3 Enhanced Efficiency and Productivity

- Applications of Laser-based Additive Manufacturing

- 5.1 Aerospace and Defense

- 5.2 Medical and Dental Industries

- 5.3 Automotive and Tooling Sectors

- Challenges in Laser-based Additive Manufacturing

- 6.1 Process Control and Optimization

- 6.2 Material Considerations

- 6.3 Post-Processing and Finishing

- Conclusion

1. Introduction

In the realm of additive manufacturing, lasers have emerged as a powerful tool, driving innovation and transforming traditional manufacturing processes. The precise and controlled nature of lasers has revolutionized the way complex parts and prototypes are produced. This article explores the crucial role of lasers in additive manufacturing, shedding light on the principles, advantages, applications, and challenges associated with laser-based additive manufacturing.

2. Understanding Additive Manufacturing

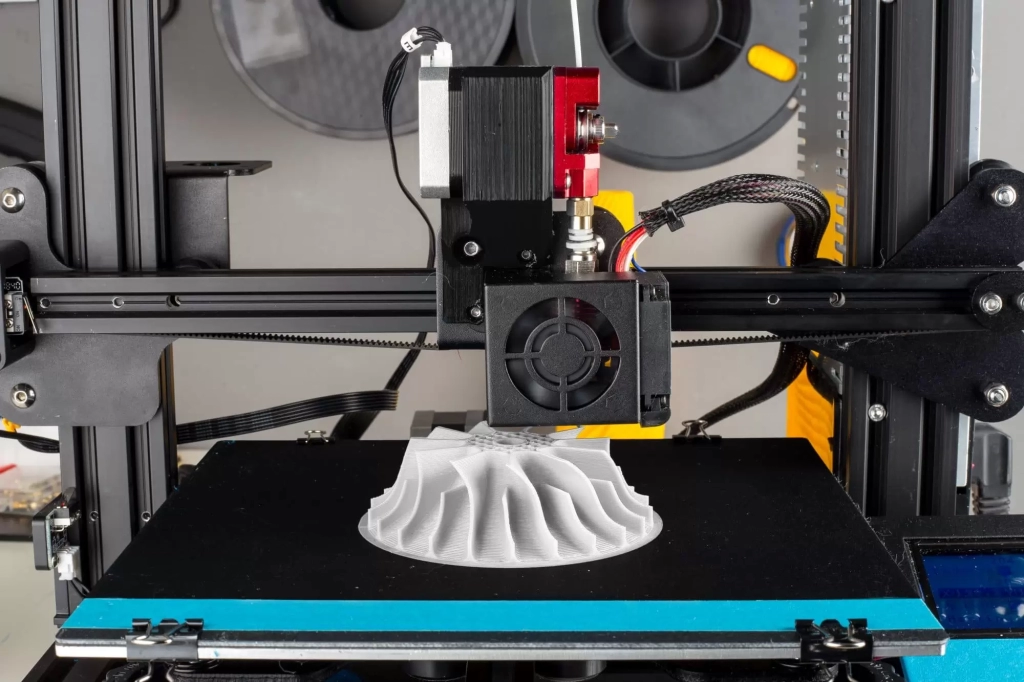

Before delving into the role of lasers, it is important to grasp the concept of additive manufacturing. Additive manufacturing, also known as 3D printing, is a process that involves building three-dimensional objects layer by layer using computer-aided design (CAD) models. Unlike subtractive manufacturing methods that involve removing material, additive manufacturing adds material in a controlled manner, resulting in a high level of precision and customization.

3. The Role of Lasers in Additive Manufacturing

3.1 Principles of Laser-based Additive Manufacturing

Laser-based additive manufacturing utilizes lasers as a heat source to selectively melt or fuse materials layer by layer. This process involves focusing a laser beam onto a specific spot on the workpiece, causing the material to melt and solidify rapidly. By precisely controlling the laser's intensity and movement, complex geometries can be built with exceptional accuracy and repeatability.

3.2 Laser Sources for Additive Manufacturing

Various types of lasers are employed in additive manufacturing, each with its own set of advantages and applications. Common laser sources include fiber lasers, CO2 lasers, and solid-state lasers. Fiber lasers, known for their high power efficiency and beam quality, are well-suited for additive manufacturing. CO2 lasers are ideal for processing non-metallic materials, while solid-state lasers offer excellent precision and stability.

4. Advantages of Laser-based Additive Manufacturing

Laser-based additive manufacturing offers several key advantages over traditional manufacturing methods. Let's explore some of these benefits:

4.1 High Precision and Accuracy

Laser-based additive manufacturing enables the creation of intricate, complex parts with micron-level precision. The focused laser beam allows for precise control over the melting and solidification process, resulting in parts with exceptional accuracy. This level of precision opens up new possibilities in industries where tight tolerances and intricate designs are crucial.

4.2 Versatility in Materials and Applications

Laser-based additive manufacturing is compatible with a wide range of materials, including metals, polymers, ceramics, and composites. This versatilityallows manufacturers to explore different materials and tailor them to specific applications. From lightweight aerospace components to biomedical implants, lasers enable the production of parts with diverse material properties and functionalities.

4.3 Enhanced Efficiency and Productivity

Laser-based additive manufacturing offers significant improvements in efficiency and productivity compared to traditional manufacturing methods. The ability to build complex parts in a single process eliminates the need for multiple tooling and assembly steps. This reduces production time, minimizes waste, and streamlines the manufacturing workflow, leading to enhanced efficiency and overall productivity gains.

5. Applications of Laser-based Additive Manufacturing

Laser-based additive manufacturing finds extensive applications across various industries. Let's explore a few notable examples:

5.1 Aerospace and Defense

In the aerospace and defense sectors, laser-based additive manufacturing is used to produce lightweight yet robust components. Complex geometries, internal channels, and lattice structures can be created, reducing weight and enhancing fuel efficiency. Components such as turbine blades, engine parts, and structural elements benefit from the design freedom and material flexibility offered by laser-based additive manufacturing.

5.2 Medical and Dental Industries

Laser-based additive manufacturing has revolutionized the medical and dental fields, enabling the production of patient-specific implants, prosthetics, and surgical tools. The customization capabilities of laser-based additive manufacturing ensure a perfect fit and improved patient outcomes. From orthopedic implants to dental crowns, lasers play a critical role in fabricating precise, patient-specific medical devices.

5.3 Automotive and Tooling Sectors

In the automotive industry, laser-based additive manufacturing is employed for rapid prototyping, customized part production, and tooling applications. Complex geometries and lightweight structures can be created, contributing to improved vehicle performance and fuel efficiency. Additionally, laser-based additive manufacturing enables the production of specialized tooling and fixtures that enhance manufacturing processes and reduce costs.

6. Challenges in Laser-based Additive Manufacturing

While laser-based additive manufacturing offers numerous advantages, it also presents certain challenges that need to be addressed for its wider adoption.

6.1 Process Control and Optimization

Achieving consistent process control and optimization is crucial for ensuring quality and reliability in laser-based additive manufacturing. Factors such as laser power, scanning speed, and powder/material properties need to be carefully controlled to achieve the desired results. Process monitoring, feedback loops, and advanced control algorithms play a vital role in enhancing process control and optimizing the manufacturing process.

6.2 Material Considerations

The selection and compatibility of materials for laser-based additive manufacturing are critical factors. Different materials have unique properties and responses to laser energy, affecting the final part quality. Researchers and manufacturers must continually explore new materials and optimize processing parameters to expand the range of materials suitable for laser-based additive manufacturing.

6.3 Post-Processing and Finishing

Post-processing steps, including heat treatment, surface finishing, and machining, are often required to achieve the desired surface quality, mechanical properties, and dimensional accuracy. Developing efficient and cost-effective post-processing techniques specific to laser-based additive manufacturing is a challenge that needs to be addressed. Automation and integrated solutions are being explored to streamline post-processing operations.

7. Conclusion

Laser-based additive manufacturing has revolutionized the manufacturing landscape, offering high precision, versatility, and enhanced efficiency. With the ability to create complex geometries and utilize various materials, lasers are driving innovation across industries such as aerospace, medical, automotive, and more. However, addressing challenges related to process control, material considerations, and post-processing is crucial for further advancements in laser-based additive manufacturing. As technology continues to evolve, lasers will continue to play a pivotal role in shaping the future of manufacturing.

1. Laser Power in Additive Manufacturing

Laser power is a critical factor in additive manufacturing, particularly in processes like Selective Laser Melting (SLM). In SLM, a high-powered laser beam is used to selectively fuse metal powders, layer by layer, to create intricate and complex three-dimensional objects. The intensity of the laser power plays a significant role in determining the quality, accuracy, and speed of the additive manufacturing process.

2. The Effect of Laser Power in SLM

Laser power directly influences the temperature reached by the metal powders during the SLM process. Higher laser power results in increased energy input, leading to faster melting and solidification of the metal powders. This can be advantageous for rapid production of parts. However, excessively high laser power may cause issues like excessive heat accumulation, leading to part distortion, poor surface finish, and even cracks.

Conversely, lower laser power might result in incomplete melting and insufficient bonding between layers, compromising the mechanical strength and overall integrity of the finished component. Striking the right balance in laser power is crucial to achieving optimal results in SLM, ensuring parts with high density, dimensional accuracy, and superior mechanical properties.

3. Types of Lasers Used in Additive Manufacturing

In additive manufacturing, several types of lasers are utilized, each with unique properties suitable for specific applications. The most commonly used lasers in additive manufacturing include:

a. Fiber Lasers: Fiber lasers are favored for their high power efficiency, compact design, and excellent beam quality. They are commonly used in industrial additive manufacturing systems for their ability to provide precise, focused laser beams ideal for melting metal powders in SLM.

b. CO2 Lasers: Carbon dioxide (CO2) lasers are well-suited for cutting and engraving applications due to their longer wavelength. While not as commonly used in SLM, they find applications in other additive manufacturing processes like Selective Laser Sintering (SLS).

c. Nd:YAG Lasers: Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers offer high peak power and are particularly useful for welding and drilling metal components. While they are not as prevalent as fiber lasers in SLM, they have applications in niche areas of additive manufacturing.

4. Laser Light for Curing Polymer Powders in Additive Manufacturing

Indeed, laser light can be harnessed to cure polymer powders used in certain additive manufacturing processes like Selective Laser Sintering (SLS). In SLS, a laser selectively fuses polymer powders to create 3D objects. The laser heats the polymer particles just below their melting point, causing them to fuse together and form solid structures. As a result, the laser light acts as a heat source, driving the sintering process to create complex and functional parts from polymer materials.

Conclusion

Laser power is the driving force behind many additive manufacturing processes, especially in Selective Laser Melting (SLM). Striking the right balance in laser power is crucial to achieving optimal results, ensuring parts with high density and mechanical strength. In the additive manufacturing world, fiber lasers take center stage due to their efficiency and precision, making them the go-to choice for metal powder fusion in SLM.

Moreover, the potential of laser light goes beyond metals. In processes like Selective Laser Sintering (SLS), laser light can cure polymer powders, enabling the creation of complex and functional parts. As technology continues to evolve, we can expect even more fascinating applications of laser power in additive manufacturing, fueling advancements and propelling this innovative industry into the future. Stay connected with v1prototype for the latest updates on additive manufacturing and its game-changing possibilities.