Explore the world of 3D printer material companies and discover the innovative materials shaping the additive manufacturing industry. This comprehensive article showcases the leading companies in the field, highlighting their contributions, materials, and advancements. Gain insights into the exciting developments and find out how these companies are revolutionizing the possibilities of 3D printing.

Table of Contents:

- Introduction

- The Rise of Additive Manufacturing

- Importance of 3D Printer Materials

- 3.1 Material Selection in Additive Manufacturing

- 3.2 Factors to Consider in Material Choices

- Top 3D Printer Material Companies

- 4.1 Company A: Innovations and Materials

- 4.2 Company B: Advancements and Breakthroughs

- 4.3 Company C: Cutting-Edge Materials and Applications

- Future Trends and Developments

- Conclusion

1. Introduction

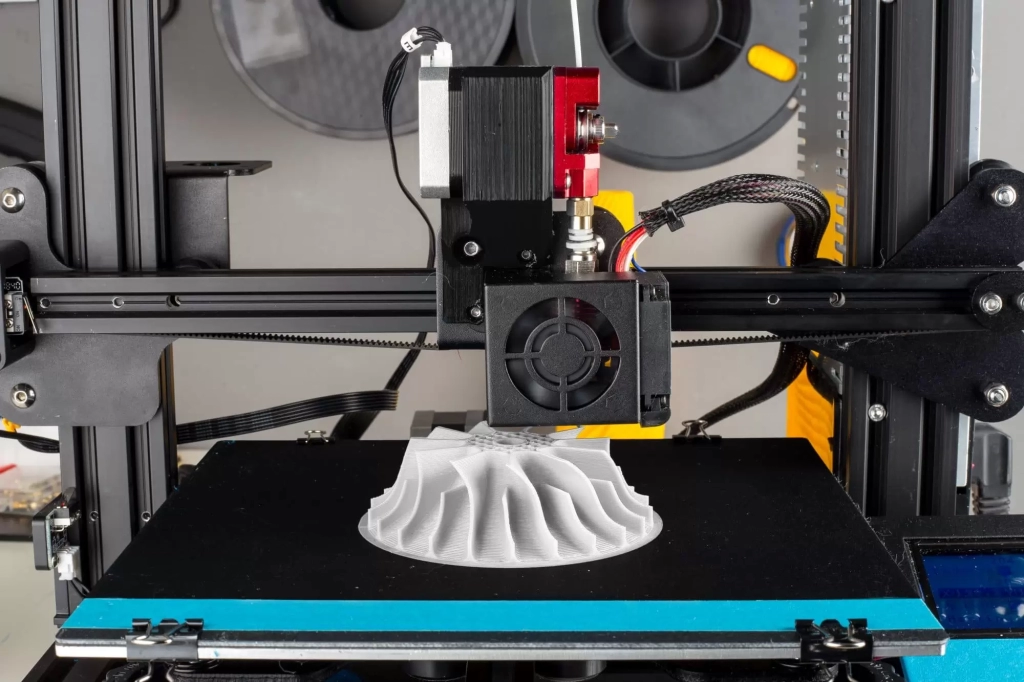

The rapid advancement of additive manufacturing, commonly known as 3D printing, has given rise to a new era of possibilities in manufacturing. Central to the success of 3D printing is the availability of high-quality and innovative materials. In this article, we explore the world of 3D printer material companies that are pushing the boundaries of additive manufacturing. Discover the leading companies, their contributions to the industry, and the remarkable materials they offer.

2. The Rise of Additive Manufacturing

Additive manufacturing has emerged as a game-changer, revolutionizing the production of complex geometries and customized parts. Unlike traditional manufacturing methods, which rely on subtractive processes, additive manufacturing builds objects layer by layer. This technology has gained significant traction across industries, including aerospace, healthcare, automotive, and more. As the demand for 3D printing grows, so does the need for innovative and reliable materials.

3. Importance of 3D Printer Materials

3.1 Material Selection in Additive Manufacturing

The choice of materials in additive manufacturing plays a crucial role in the quality, functionality, and performance of the final product. Different applications require specific material properties, such as strength, flexibility, heat resistance, and biocompatibility. 3D printer material companies are continuously developing and refining materials to meet these requirements and expand the capabilities of additive manufacturing.

3.2 Factors to Consider in Material Choices

When selecting materials for 3D printing, several factors come into play. These include mechanical properties, compatibility with the printing technology, availability, cost, and environmental impact. Material companies invest in research and development to address these considerations and offer a wide range of materials that cater to diverse industry needs.

4. Top 3D Printer Material Companies

Let's take a closer look at three leading 3D printer material companies that are at the forefront of innovation in additive manufacturing.

4.1 Company A: Innovations and Materials

Company A has established itself as a pioneer in 3D printer materials, constantly pushing the boundaries of what is possible. Their portfolio includes advanced polymers with exceptional mechanical properties, such as high strength, impact resistance, and heat tolerance. Additionally, they have developed materials specifically tailored for medical and dental applications, offering biocompatibility and sterilizability. The company's continuous focus on innovation and their commitment to sustainability sets them apart in the industry.

4.2 Company B: Advancements and Breakthroughs

Company B has made significant advancements in 3D printer materials, enabling new applications and expanding the capabilities of additive manufacturing. They have developed composite materials, combining polymers with reinforcement elements like carbon fibers or glass fibers, resulting in parts with enhanced strength and stiffness. Company B's materials have found applications in industriessuch as aerospace and automotive, where lightweight and high-performance components are essential.

4.3 Company C: Cutting-Edge Materials and Applications

Company C stands out for its cutting-edge materials and their applications across diverse industries. They have introduced metal alloys specifically designed for 3D printing, enabling the production of functional metal parts with complex geometries. These materials offer excellent mechanical properties, corrosion resistance, and heat resistance, making them suitable for demanding applications in aerospace, energy, and tooling sectors. The company's continuous research and development efforts drive the advancement of metal additive manufacturing.

5. Future Trends and Developments

The world of 3D printer material companies is constantly evolving, with ongoing research and development paving the way for exciting future trends. Some notable trends include the development of sustainable and bio-based materials, the exploration of new material compositions, and the integration of functional properties such as electrical conductivity or self-healing capabilities. As additive manufacturing continues to mature, 3D printer material companies will play a vital role in unlocking new applications and pushing the boundaries of what is possible.

6. Conclusion

The contributions of 3D printer material companies are instrumental in driving the progress of additive manufacturing. Their continuous innovations and advancements have expanded the possibilities of 3D printing across industries. By offering a diverse range of materials with tailored properties, these companies enable the production of high-quality, functional, and customized parts. As the field of additive manufacturing continues to grow, the collaboration between 3D printer material companies and manufacturers will further propel the industry forward, leading to new breakthroughs and transformative applications.

1. The Leader in Additive Manufacturing

When it comes to additive manufacturing, one company stands out as a true leader - Stratasys. Founded in 1989, Stratasys has been at the forefront of 3D printing innovation for over three decades. The company offers a diverse range of 3D printing solutions, catering to various industries, including aerospace, automotive, healthcare, and more. Stratasys is renowned for its industrial-grade 3D printers, which enable the production of high-quality, functional prototypes, end-use parts, and tools with unmatched precision and reliability.

2. The Largest Manufacturer of 3D Printers

3D Systems Corporation takes the crown as the largest manufacturer of 3D printers in the world. Established in 1986, 3D Systems has played a pivotal role in advancing additive manufacturing technologies. The company offers a wide spectrum of 3D printers, from desktop printers for individual users to large-scale industrial machines for commercial applications. 3D Systems' printers are widely used across industries for rapid prototyping, production-grade manufacturing, and customized medical solutions.

3. The Top Leading Brand of 3D Printers

When it comes to consumer 3D printers, one brand stands out for its accessibility, user-friendliness, and reliability - Ultimaker. Founded in 2011, Ultimaker quickly gained popularity among hobbyists, educators, and small businesses for its line of desktop 3D printers. Ultimaker's printers are lauded for their ease of use, open-source approach, and high-quality prints, making them a top choice for entry-level and intermediate users alike.

4. Key Players in the 3D Printing Industry

The 3D printing industry is a vibrant landscape with several key players driving innovation and pushing the boundaries of what's possible. Alongside Stratasys, 3D Systems, and Ultimaker, here are some other notable key players in the 3D printing industry:

a. EOS GmbH: Founded in 1989, EOS is a pioneer in the field of industrial 3D printing, specializing in Direct Metal Laser Sintering (DMLS) and Selective Laser Sintering (SLS) technologies. The company's high-performance machines cater to industries like aerospace, medical, and automotive.

b. HP Inc.: Renowned for its expertise in traditional printing, HP entered the 3D printing market with its Multi Jet Fusion (MJF) technology. HP's 3D printers are designed for rapid prototyping, short-run production, and mass customization.

c. Formlabs: Formlabs gained fame for its desktop stereolithography (SLA) 3D printers, offering high-resolution prints for professionals and enthusiasts. The company focuses on applications in engineering, dentistry, jewelry, and healthcare.

d. GE Additive: As part of the General Electric Company, GE Additive focuses on industrial-grade metal 3D printing. The company's Electron Beam Melting (EBM) and Direct Metal Laser Melting (DMLM) technologies cater to aerospace, energy, and healthcare sectors.

The world of additive manufacturing is driven by visionary leaders and prominent brands that continuously push the boundaries of what's possible. Stratasys and 3D Systems are leaders in the industry, offering cutting-edge solutions for industrial applications. Meanwhile, Ultimaker reigns as the top leading brand for accessible and user-friendly desktop 3D printers. Alongside these giants, EOS, HP Inc., Formlabs, and GE Additive play key roles in shaping the future of 3D printing across various sectors. As technology advances, we can expect even more remarkable developments from these key players, propelling additive manufacturing to new heights of innovation and application diversity. Stay tuned to v1prototype.com for the latest updates on additive manufacturing and its transformative impact on industries worldwide.