The Role of Rapid Prototyping in Industrial Modeling

Across various industrial sectors, rapid prototyping technologies have revolutionized product development processes. By enabling engineers to create accurate physical prototypes of complex parts and assemblies in a fraction of the time required by conventional methods, rapid prototyping streamlines validation of design concepts and improves end product quality. This has particular benefits for industrial modeling applications where prototypes are essential.Prototyping Aids Design Exploration

In industrial modeling, rapid prototyping helps design teams iteratively explore a wide range of potential solutions in the conceptual phase. Engineers can produce numerous prototype designs in parallel to evaluate form, fit and function factors that are difficult to gauge virtually. Testing real prototypes early improves understanding of manufacturability, assembly, ergonomics and other considerations to guide model refinement. This maximizes valuable early design flexibility.Validating Feasibility of Complex Geometries

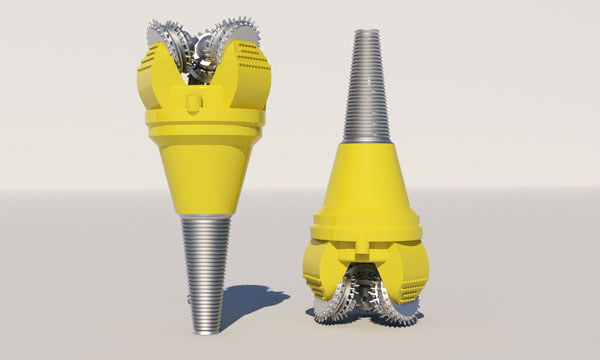

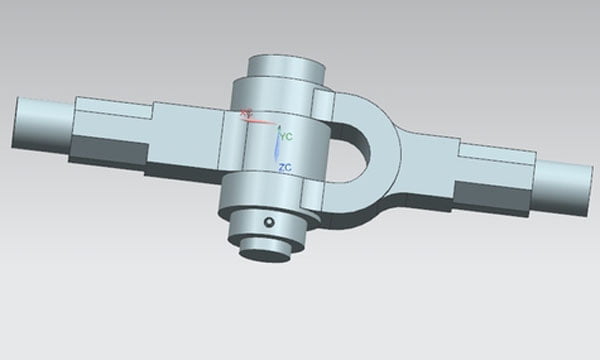

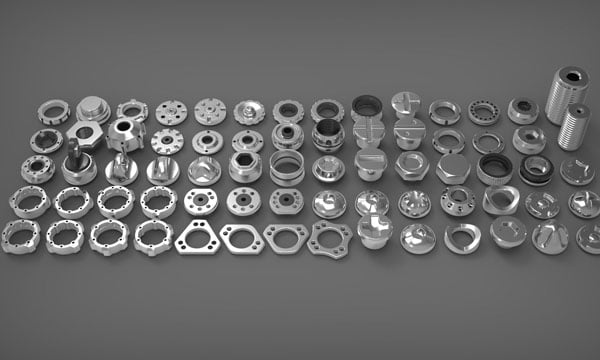

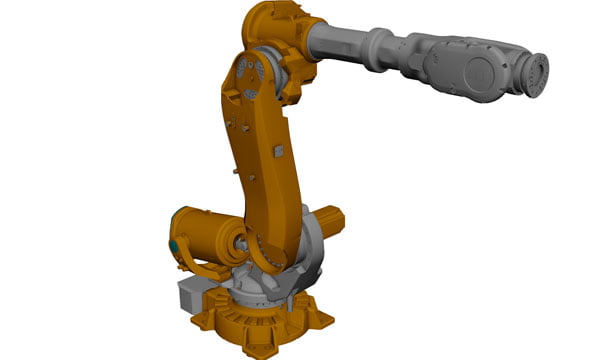

Producing prototypes of complex industrial components with tight tolerances, moving parts or intricate geometries poses challenges for conventional machining. Rapid prototyping addresses this through layer-by-layer fabrication direct from 3D CAD data. Engineers leverage this to obtain high-fidelity prototypes of proposed designs for first-article verification before proceeding to soft or hard tooling. Seeing designs physically helps validate manufacturing feasibility that may be uncertain in software alone.Assembling Prototypes For Systems Testing

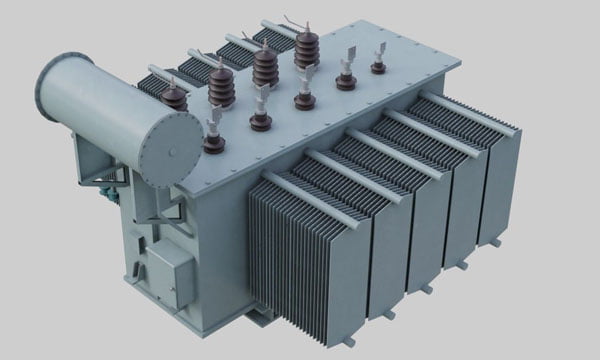

Testing industrial models as complete systems is essential but difficult without rapid prototyping. Engineers assemble various prototype parts and integrate mechanical, electrical and software elements for thorough performance validation before committing to production. Iteratively prototyped systems uncover interface issues and optimization opportunities not found through piecemeal prototyping. This yields robust and reliable industrial machine designs.Prototyping Tooling and Fixtures For Trials

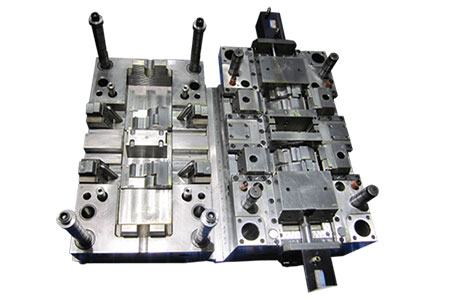

During factory equipment modeling, producing accurate rapid prototypes of associated tooling, molds, dies or fixtures enables realistic production trials well before manufacturing commences. Engineers identify weaknesses and ensure tooling/workpiece interfaces function as intended. Refining prototyped tooling aligns later production tooling with design requirements, preventing costly reworks or delayed equipment installation.Evolving Complex Industrial Products Swiftly

By facilitating frequent design iteration, prototyping grants engineers time to envision ambitious industrial models beyond traditional constraints. Complex multi-material, multipart or moving component prototypes enable far richer concept exploration than common CAD models alone. This evolves end products rapidly towards the performance frontiers, driving innovative solutions meeting modern manufacturing demands. In conclusion, rapid prototyping accelerates and enhances industrial modeling by empowering comprehensive and efficient design verification. Faster prototyping cycles maximize flexibility for refinement while de-risking ambitious concepts. The ability to produce accurate physical representations of complex systems and tooling prototypes has revolutionized equipment development to yield dependably optimized industrial machinery.Professional rapid prototyping services

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: [email protected]

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850