Explore the fascinating world of additive manufacturing and delve into the intricacies of the direct process. This comprehensive article provides insights into the various aspects of direct processes in additive manufacturing, including its definition, advantages, applications, and challenges. Gain a deeper understanding of this cutting-edge technology and its potential to revolutionize manufacturing industries.

Table of Contents:

- Introduction

- What is Additive Manufacturing?

- The Direct Process in Additive Manufacturing

- 3.1 The Concept of Direct Process

- 3.2 How Does the Direct Process Work?

- Advantages of the Direct Process

- 4.1 Increased Design Freedom

- 4.2 Enhanced Manufacturing Efficiency

- 4.3 Reduction in Material Waste

- Applications of the Direct Process

- 5.1 Aerospace Industry

- 5.2 Medical Field

- 5.3 Automotive Sector

- Challenges in the Direct Process

- 6.1 Material Selection and Compatibility

- 6.2 Post-Processing Requirements

- 6.3 Quality Control and Standardization

- Conclusion

1. Introduction

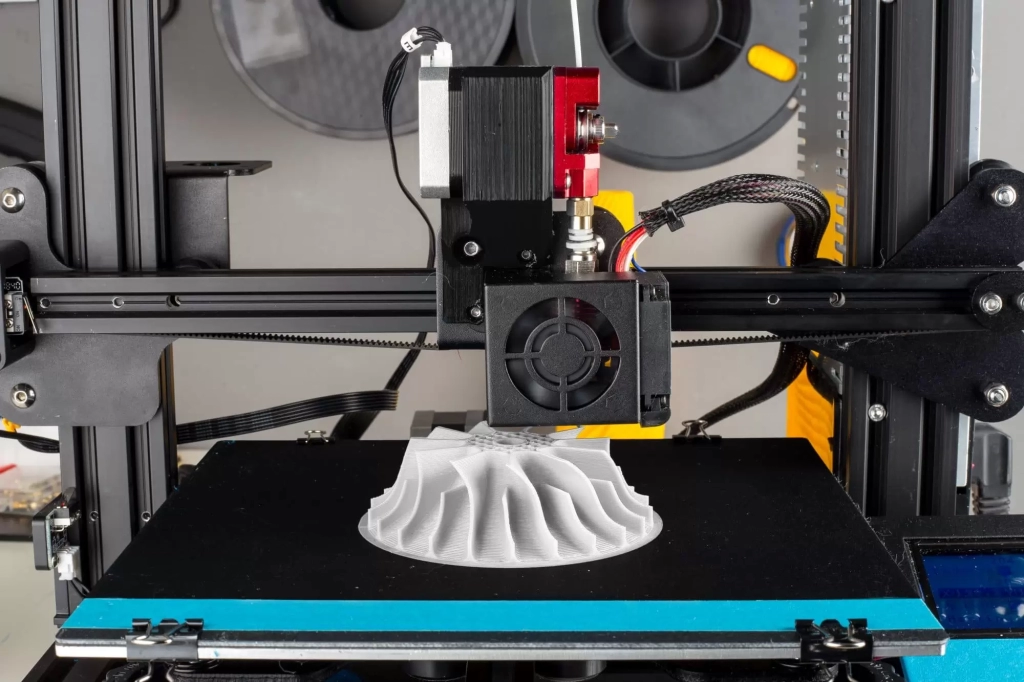

The world of manufacturing is undergoing a transformative revolution, and one technology at the forefront is additive manufacturing. Additive manufacturing, also known as 3D printing, has gained significant attention for its ability to fabricate complex geometries with ease. One of the key processes within additive manufacturing is the direct process, which allows for the direct production of functional parts. In this article, we will delve into the direct process in additive manufacturing, exploring its definition, functioning, advantages, applications, and the challenges it faces.

2. What is Additive Manufacturing?

Before we dive into the direct process, it's essential to understand the broader concept of additive manufacturing. Additive manufacturing refers to the process of building three-dimensional objects layer by layer, using computer-aided design (CAD) data. Unlike traditional subtractive manufacturing techniques that involve cutting, drilling, or milling, additive manufacturing adds material to create the desired shape. This technology has revolutionized the manufacturing industry by enabling the production of complex, customized parts with high precision.

3. The Direct Process in Additive Manufacturing

3.1 The Concept of Direct Process

The direct process in additive manufacturing involves the direct fabrication of functional parts without the need for intermediate steps. It eliminates the traditional manufacturing processes such as casting or machining, enabling the direct conversion of digital designs into physical objects. The direct process streamlines the production workflow, reducing lead times and costs associated with tooling and assembly.

3.2 How Does the Direct Process Work?

The direct process begins with the creation of a digital model using computer-aided design (CAD) software. This digital model serves as the blueprint for the object to be produced. The next step involves slicing the digital model into thin layers, typically ranging from tens to hundreds of microns in thickness. The additive manufacturing system then builds the object layer by layer, precisely depositing or solidifying the material based on the sliced model. The direct process can utilize various additive manufacturing technologies, such as fused deposition modeling (FDM), selective laser sintering (SLS), or stereolithography (SLA), depending on the specific requirements of the application.

4. Advantages of the Direct Process

The direct process offers several advantages over traditional manufacturing methods. Let's explore some of these benefits:

4.1 Increased Design Freedom

Additive manufacturing, particularly the direct process, allows for unprecedented design freedom. Complex geometries, internal channels, and intricate features that were once challenging to produce can now be easily realized. This freedom enables engineers and designers to optimize the functionality and performanceof parts, leading to innovative designs and improved product performance.

4.2 Enhanced Manufacturing Efficiency

The direct process eliminates the need for multiple manufacturing steps, such as tooling and assembly, which are common in traditional manufacturing. This reduction in process complexity translates into increased manufacturing efficiency. The direct process enables rapid production, shorter lead times, and on-demand manufacturing, making it highly suitable for prototyping, customization, and small-batch production.

4.3 Reduction in Material Waste

Traditional manufacturing often involves significant material waste due to subtractive processes, where excess material is removed to achieve the desired shape. In contrast, the direct process in additive manufacturing is an additive technique, which means material is added only where it is needed. This leads to a substantial reduction in material waste, making additive manufacturing, including the direct process, a more sustainable and environmentally friendly manufacturing method.

5. Applications of the Direct Process

The direct process in additive manufacturing finds applications in various industries. Here are a few notable examples:

5.1 Aerospace Industry

The aerospace sector benefits greatly from the direct process due to its ability to produce lightweight and complex components with high strength-to-weight ratios. Additive manufacturing allows for the creation of intricate designs, such as lattice structures, which offer weight reduction without compromising structural integrity. Components like turbine blades, fuel nozzles, and brackets are commonly produced using the direct process.

5.2 Medical Field

In the medical field, the direct process has revolutionized the production of patient-specific implants and prosthetics. With additive manufacturing, customized medical devices can be created based on individual patient scans, ensuring a perfect fit. The direct process enables the fabrication of intricate and porous structures that promote osseointegration, allowing for better integration of implants with natural bone tissue.

5.3 Automotive Sector

Automotive manufacturers leverage the direct process for rapid prototyping, tooling, and production of specialized components. Additive manufacturing enables the creation of lightweight parts with complex geometries, contributing to fuel efficiency and performance. Applications include intake manifolds, brackets, custom jigs and fixtures, and interior components.

6. Challenges in the Direct Process

While the direct process in additive manufacturing offers numerous advantages, it also presents certain challenges that need to be addressed for its wider adoption.

6.1 Material Selection and Compatibility

Selecting suitable materials for the direct process can be challenging. Not all materials are compatible with additive manufacturing technologies, and the properties of the materials can impact the performance and reliability of the fabricated parts. Extensive research and development are required to identify and qualify materials suitable for the direct process.

6.2 Post-Processing Requirements

After the direct process, post-processing steps may be necessary to achieve the desired surface finish, accuracy, and mechanical properties. Depending on the application and the additive manufacturing technology used, post-processing steps such as heat treatment, polishing, or machining may be required. Developing efficient and cost-effective post-processing techniques is crucial to fully capitalize on the advantages of the direct process.

6.3 Quality Control and Standardization

Ensuring consistent quality and reliable performance of parts produced through the direct process is essential. Establishing quality control measures, inspection techniques, and standardized testing methods specific to additive manufacturing are ongoing challenges. The direct process requires robust quality assurance processes to ensure that the fabricated parts meet the required specifications and performance criteria.

7. Conclusion

The direct process in additive manufacturing is a revolutionary technology with the potential to transform manufacturing industries. By enabling the direct fabrication of functional parts, this process offers increased design freedom, enhanced manufacturing efficiency, and reduced material waste. Its applications span across aerospace, medical, automotive, and various other sectors. However, challenges such as material selection, post-processing requirements, and quality control need

Additive Manufacturing (AM), also known as 3D printing, is a revolutionary manufacturing process that creates three-dimensional objects by adding material layer by layer. There are several processes and approaches in AM, including direct and indirect processes, as well as direct and indirect tooling.

- Direct and Indirect Processes in Additive Manufacturing:

Direct Process: In the direct process of additive manufacturing, the final product is created directly from the raw material. This means that the material used to build the object is the same material that constitutes the final product. The most common example of direct additive manufacturing is when a 3D printer uses a specific material (e.g., plastic, metal, ceramic) to build a part layer by layer until the final object is formed.

Indirect Process: In the indirect process, additive manufacturing is used to create a mold or tool that will be used to produce the final product using traditional manufacturing methods. The mold or tool, created through AM, is then used to shape the raw material into the desired form. This method is particularly useful when traditional manufacturing processes may be costly or time-consuming.

- Processes of Additive Manufacturing:

There are various additive manufacturing processes, each utilizing different techniques and materials. Some of the most common processes include:

- Fused Deposition Modeling (FDM)/Fused Filament Fabrication (FFF): A filament of thermoplastic material is fed through a heated nozzle, which deposits the material layer by layer to create the object.

- Stereolithography (SLA): It uses a liquid photopolymer resin that is cured layer by layer using an ultraviolet (UV) laser or light source.

- Selective Laser Sintering (SLS): A high-power laser selectively sinters or fuses powdered material, typically polymers or metals, to create the object's layers.

- Direct Metal Laser Sintering (DMLS)/Selective Laser Melting (SLM): Similar to SLS, but used with metal powders to create metal parts.

- Electron Beam Melting (EBM): An electron beam is used to melt and fuse metal powders together to create metal parts.

- Binder Jetting: A liquid binding agent is selectively deposited onto a powdered material bed, layer by layer, to bind the particles together and form the object.

- Material Jetting: Layers of material are selectively deposited using inkjet printhead technology.

- Laminated Object Manufacturing (LOM): Layers of material, typically paper or plastic, are cut and glued or fused together to build the object.

- Direct Tooling and Indirect Tooling in Additive Manufacturing:

Direct Tooling: In additive manufacturing, direct tooling refers to the process of 3D printing tools, molds, or dies directly for use in various manufacturing processes. These 3D-printed tools are designed to withstand the demands of production and are utilized in processes such as injection molding, casting, or stamping.

Indirect Tooling: Indirect tooling, on the other hand, involves using additive manufacturing to create patterns, molds, or tooling for traditional manufacturing methods. For example, a 3D-printed pattern may be used to create a sand mold for metal casting or a master model to produce a silicone mold for resin casting.

Both direct and indirect tooling in additive manufacturing offer advantages such as rapid prototyping, design flexibility, and reduced lead times compared to conventional tooling methods.