Enhancing Medical Device Design and Development Through Rapid Prototyping

The medical technology field places a premium on innovation to solve pressing healthcare challenges, but strict regulations require rigorous testing of new devices. Rapid prototyping helps accelerate this process by enabling design validation and functional assessments early in development cycles. This proven technology plays a vital role in optimizing medical instruments to benefit both patients and practitioners.Facilitating Design Verification

Rapid prototyping allows medical device designers to produce detailed anatomical models, functional components and full assembly prototypes concurrently for comprehensive evaluation. Testing fit and form verifies designs accommodate clinical workflows efficiently. Prototypes uncover potential manufacturability issues that could otherwise delay projects. This provides valuable feedback to refine concepts before costly regulatory submissions.Streamlining Functional Testing

Producing beta prototypes for functional testing enables replicating intended surgical or exam procedures under realistic conditions. Simulating tool handling characteristics finds ergonomic flaws. Assessing device durability and material properties mitigates risk of performance issues discovered late. Iterative testing supports continuous improvements ensuring tool longevity and reliability. Prototypes also facilitate usability studies with clinicians.Customization and Surgical Simulation

Patient-specific rapid prototypes facilitate personalized surgical planning and customized medical tools. Prototyping anatomical models from medical scans enables dry run procedures to optimize approaches. Surgical simulators leverage realistic 3D printing for training complex tasks. Prototyping tools trimmed for individual anatomies further refine customization lowering procedural risks.Enhancing User Experience

Manufacturing prototypes from the design phase offers opportunities for user experience studies. Gathering clinician and patient feedback on ergonomics and functionality informs refinements boosting adoption. Prototyping mock-ups for trade shows and demonstrations aid market evaluation of new concepts. Early user engagement leverages market insights to optimize products addressing unmet needs.Advancing Through Iteration

Rapid design-test-redesign cycles compress product development timelines, an important factor given healthcare time sensitivities. By enabling multiple prototype iterations concurrently engineers address issues proactively rather than through costly post-market fixes. Faster development positions innovators to deliver breakthrough solutions satisfying unmet needs sooner for improved patient outcomes. In conclusion, rapid prototyping has revolutionized medical device design by facilitating comprehensive product validation earlier. This compressed development approach de-risks new innovations, optimizes user experiences and regulatory compliance, ensuring medical technologies efficiently fulfill their potential to transform patient care.Professional rapid prototyping services

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

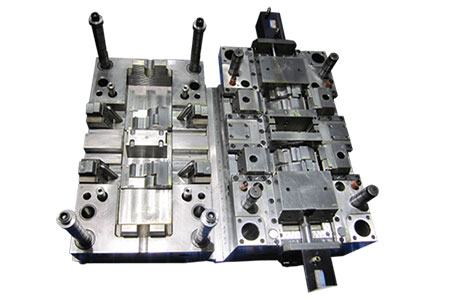

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: info@v-1.com

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850