Discover the innovative world of sheet additive manufacturing. This comprehensive guide explores the process, benefits, applications, and future prospects of this cutting-edge technology.

Table of Contents:

- Introduction

- Understanding the Sheet Additive Manufacturing Process

- 2.1 What is Sheet Additive Manufacturing?

- 2.2 How Does the Process Work?

- Benefits of Sheet Additive Manufacturing

- 3.1 Design Freedom and Complexity

- 3.2 Improved Efficiency and Reduced Waste

- 3.3 Enhanced Functionality and Performance

- Applications of Sheet Additive Manufacturing

- 4.1 Aerospace and Defense

- 4.2 Automotive Industry

- 4.3 Medical and Healthcare Sector

- 4.4 Consumer Goods and Electronics

- Future Prospects of Sheet Additive Manufacturing

- 5.1 Advancements in Materials and Processes

- 5.2 Integration of Industry 4.0 Technologies

- 5.3 Sustainability and Environmental Impact

- Conclusion

1. Introduction

In recent years, additive manufacturing has revolutionized the manufacturing industry by enabling the production of complex and customized parts with ease. One emerging technology within the additive manufacturing field is sheet additive manufacturing. This comprehensive guide aims to delve into the world of sheet additive manufacturing, exploring its process, benefits, applications, and future prospects. Join us as we embark on this exciting journey into the world of sheet additive manufacturing.

2. Understanding the Sheet Additive Manufacturing Process

2.1 What is Sheet Additive Manufacturing?

Sheet additive manufacturing is a unique 3D printing technique that utilizes thin sheets of material to build objects layer by layer. Unlike traditional 3D printing methods that use filament or liquid resin, sheet additive manufacturing employs sheet materials, such as metal or polymers, that are stacked together to form the final object. This process offers distinct advantages in terms of design complexity, material efficiency, and functionality.

2.2 How Does the Process Work?

The sheet additive manufacturing process involves multiple steps. First, the CAD model of the desired object is sliced into thin cross-sectional layers. These layers are then digitally transferred to a cutting machine, which precisely cuts the sheets into the required shapes. The cut sheets are stacked together, and each layer is bonded using various techniques such as welding, adhesive bonding, or thermal processes. This layer-by-layer approach allows for the creation of intricate and precise structures.

3. Benefits of Sheet Additive Manufacturing

3.1 Design Freedom and Complexity

Sheet additive manufacturing offers unparalleled design freedom and complexity. The ability to use thin sheets allows for intricate geometries, including curved and organic shapes, that are difficult to achieve with traditional manufacturing methods. This technology enables designers and engineers to push the boundaries of creativity and innovation, resulting in highly complex and functional products.

3.2 Improved Efficiency and Reduced Waste

Sheet additive manufacturing improves manufacturing efficiency by reducing material waste. The process optimizes material usage by stacking and bonding multiple thin sheets, minimizing scrap and offcuts. This reduction in waste contributes to cost savings and environmental sustainability. Additionally, the high accuracy and repeatability of the process reduce the need for post-processing and rework, further enhancing overall production efficiency.

3.3 Enhanced Functionality and Performance

By leveraging sheet materials, additive manufacturing can create objects with enhanced functionality and performance. The use of multiple materials within a single object allows for the integration of different properties, such as strength, flexibility, and conductivity. This capability opens up new possibilities in various industries, enabling the production of lightweight structures, heat sinks, and multi-functional components.

4. Applications of Sheet Additive Manufacturing

4.1 Aerospace and Defense

In the aerospace and defense industries, sheet additive manufacturing offers numerous benefits. The ability to create lightweight structures with complex geometries is highly advantageous for aerospace applications. From aircraft components to satellite parts, sheet additive manufacturing enables the production of high-performance and reliable parts that meet stringent industry standards.

4.2 Automotive Industry

The automotive industry is another sector that can benefit greatly from sheet additive manufacturing. This technology allows for the production of complex automotive components, including engine parts, chassis components, and lightweight structural elements. Sheet additive manufacturing offers the automotive industry the opportunity to improve fuel efficiency, reduce vehicle weight, and enhance overall performance.

4.3 Medical and Healthcare Sector

Sheet additive manufacturing has significant applications in the medical and healthcare sector. The ability to create patient-specific implants, prosthetics, and surgical tools is invaluable for personalized medicine. Sheet additive manufacturing enables the production of custom-fit medical devices, reducing surgical time and improving patient outcomes. Additionally, this technology allows for the fabrication of intricate anatomical models for surgical planning and education.

4.4 Consumer Goods and Electronics

The consumer goods and electronics industries can also leverage the benefits of sheet additive manufacturing. This technology enables the production of lightweight and high-performance consumer products such as eyewear, jewelry, and electronic device components. The ability to create intricate and functional designs with precise tolerances opens up new possibilities for product innovation and customization.

5. Future Prospects of Sheet Additive Manufacturing

5.1 Advancements in Materials and Processes

As sheet additive manufacturing continues to evolve, advancements in materials and processes will drive its future prospects. The development of new sheet materials with enhanced properties, such as improved strength, conductivity, and heat resistance, will expand the range of applications. Additionally, advancements in bonding techniques and process automation will further improve the efficiency and scalability of sheet additive manufacturing.

5.2 Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies, such as artificial intelligence, machine learning, and robotics, will play a significant role in the future of sheet additive manufacturing. These technologies will enable real-time monitoring, process optimization, and predictive maintenance, resulting in increased productivity, quality, and reliability. The intelligent integration of these technologies will streamline the sheet additive manufacturing process and open doors to new possibilities.

5.3 Sustainability and Environmental Impact

Sustainability and environmental considerations will shape the future of sheet additive manufacturing. With an increasing focus on eco-friendly manufacturing, efforts are being made to develop recyclable and biodegradable sheet materials. Moreover, the reduction of energy consumption and waste generation in the sheet additive manufacturing process will contribute to a more sustainable manufacturing ecosystem.

6. Conclusion

Sheet additive manufacturing is an exciting and innovative technology that offers unique advantages in design complexity, material efficiency, and functionality. The process allows for the creation of intricate and precise structures, opening up new possibilities across industries such as aerospace, automotive, healthcare, and consumer goods. As the technology continues to advance, we can expect to see further improvements in materials, processes, and the integration of Industry 4.0 technologies. Sheet additive manufacturing has the potential to revolutionize traditional manufacturing processes and drive innovation in the production of complex and customized products. Stay at the forefront of this evolving technology to unlock its full potential in your industry.

The steps of the additive manufacturing (AM) process can vary depending on the specific technology being used, but generally, they include the following:

- Design: The process starts with creating a 3D digital model of the object to be produced. This can be done using computer-aided design (CAD) software or obtained through 3D scanning technologies.

- Slicing: The 3D digital model is sliced into thin horizontal layers or cross-sections. These layers serve as the building blocks for the additive manufacturing process.

- Preparation: Before printing, the 3D printer and the build platform need to be prepared. This may involve calibrating the printer, setting the print parameters, and ensuring the build platform is clean and ready.

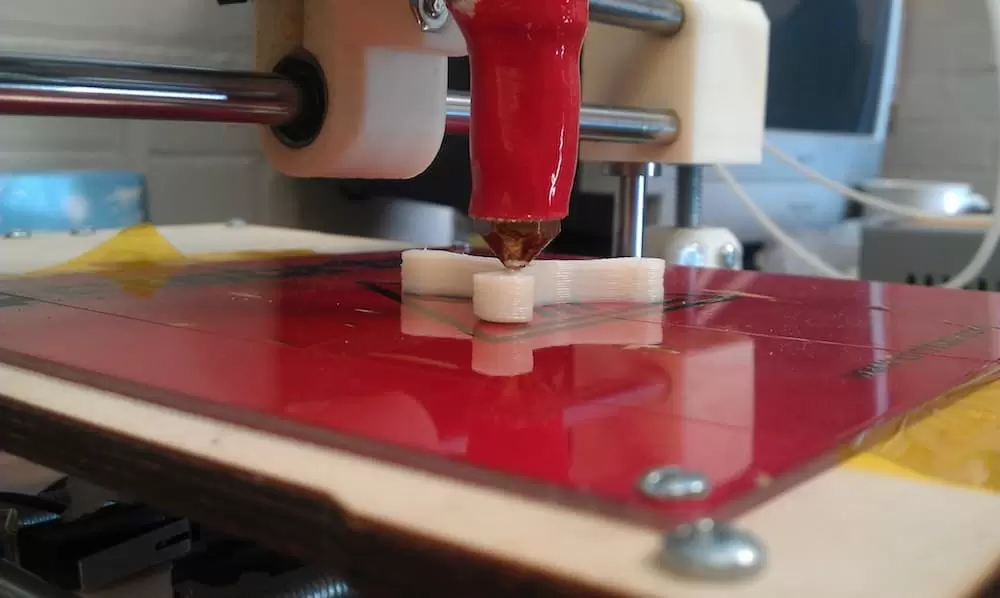

- Printing/Additive Process: The 3D printer starts building the object layer by layer, following the instructions from the sliced digital model. The specific additive process used (e.g., FDM, SLA, SLS) determines the method of material deposition or curing.

- Cooling or Curing: In some AM technologies, such as photopolymer-based processes, the printed layers may need to be cured or cooled before proceeding to the next layer.

- Support Structures (if needed): Some AM processes may require support structures to be printed along with the object to provide stability during the printing process. These supports are removed after printing is complete.

- Post-Processing: After the printing is finished, post-processing steps may be necessary, such as removing support structures, cleaning the printed object, and performing any additional finishing operations like sanding or painting.

- Inspection and Quality Control: The final printed object may undergo inspection to ensure it meets the required specifications and quality standards.

- Application or Use: The 3D-printed object is ready for its intended application, whether it's a prototype, end-use part, tooling, or other functional components.

Now, moving on to the second part of your question:

Sheet Lamination Additive Manufacturing is one of the seven types of additive manufacturing processes. In this category of AM, sheets of material (usually paper, plastic, or metal) are layered and bound together using various techniques. The primary advantage of sheet lamination is that it allows for the creation of larger parts and can be relatively cost-effective.

Different types of sheet lamination additive manufacturing include:

- Laminated Object Manufacturing (LOM): LOM involves cutting sheets of material, typically paper or plastic, into the shape of each layer. These layers are then bonded together using heat, adhesive, or ultrasonic welding. Once the object is complete, excess material is usually removed.

- Ultrasonic Additive Manufacturing (UAM): UAM utilizes thin sheets of metal, which are bonded together using ultrasonic vibrations. Metal foil sheets are placed on top of each other and ultrasonic welding is used to create a solid metal part.

Each type of additive manufacturing process has its strengths, limitations, and specific applications. The choice of process depends on factors such as the required material, resolution, complexity, size, and end-use application of the printed object.