Table of Contents:

- Introduction to Plastic Mold Manufacturers

- Types of Plastic Molds

- Materials Used in Plastic Molding

- Plastic Mold Manufacturing Processes

- Best Practices for Working with Plastic Mold Manufacturers

- Applications of Plastic Molded Products

- Trends and Innovations in Plastic Mold Manufacturing

- Challenges and Solutions in Plastic Mold Manufacturing

- Conclusion and Future Outlook

-

1. Introduction to Plastic Mold Manufacturers

A. What is a Plastic Mold Manufacturer?

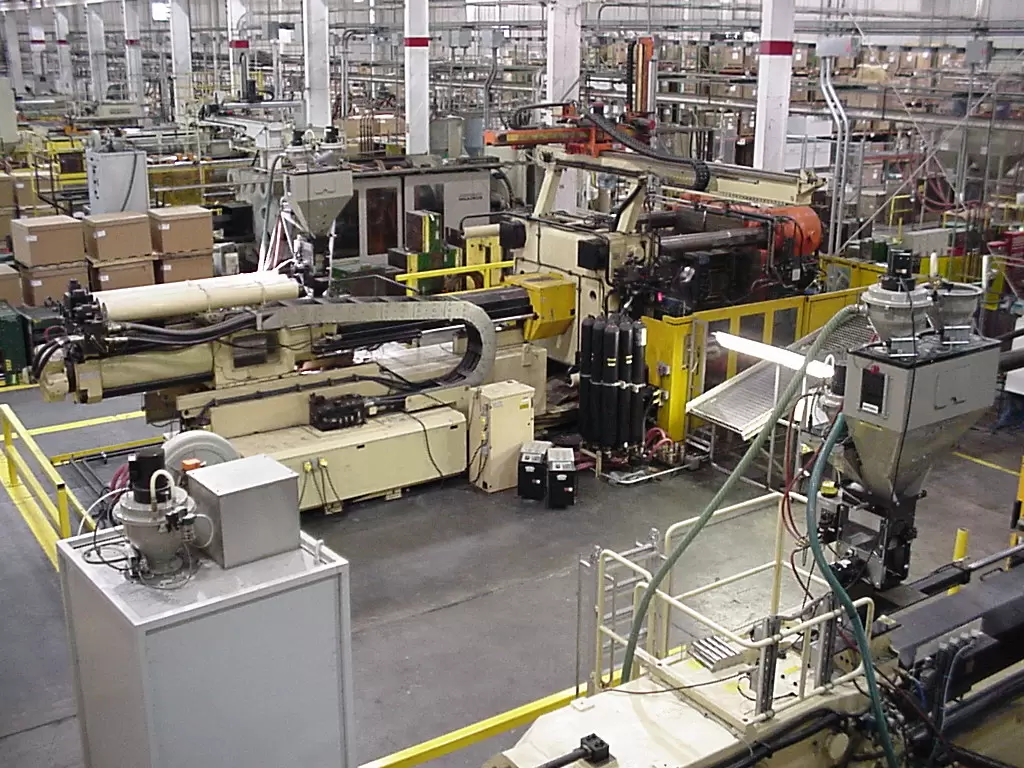

A plastic mold manufacturer is a specialized company that produces industrial parts and products by using a mold, which can be made of a variety of materials, such as plastic, metal, or ceramic.

B. Importance of Plastic Mold Manufacturers

Plastic mold manufacturers play a critical role in modern manufacturing by providing an efficient and cost-effective way to produce a large number of identical items with high precision and accuracy.

C. Benefits of Working with a Plastic Mold Manufacturer

Collaborating with a plastic mold manufacturer can offer many benefits, such as reduced production time, lower costs, and improved product quality. These benefits become more apparent when working on large-scale projects or those that require complex shapes or high accuracy.

-

2. Types of Plastic Molds

A. Injection Molds

Injection molds are one of the most popular plastic mold types, as they are versatile and can create complex shapes. Injection molding is often used for mass production of industrial components such as automotive parts.

B. Blow Molds

Blow molds use pressurized air to expand a hollow material such as plastic, creating a specific shape. This plastic mold type is used for creating products such as bottles, containers, and storage tanks.

C. Thermoforming Molds

Thermoforming molds utilize heating and cooling to shape and mold thermoplastic materials into desired configurations like trays, containers, and enclosures.

D. Rotational Molds

Rotational molds or rotomolding, involve heating, rotating, and cooling hollow plastic material or resin to create seamless, uniform products such as fuel tanks and playground equipment.

E. Extrusion Molds

Extrusion molds are used to form continuous plastic products of specific shapes and sizes with high throughput speeds.

-

3. Materials Used in Plastic Molding

A. Thermoplastics

Thermoplastics are versatile materials that can be repeatedly melted and remolded. Some common thermoplastic materials include polyethylene, polypropylene, polyvinyl chloride, and polystyrene.

B. Thermosetting Plastics

Thermosetting plastics are plastics that undergo permanent chemical changes, rendering them unprocessable once they have been molded. Some common thermosetting plastic materials include urea, melamine, and phenolic resins.

C. Elastomers

Elastomers are materials that exhibit elasticity or stretchability. Some common elastomer materials include rubber and silicone.

D. Metals

Metals can be molded using different techniques such as casting and forging. Some metals that are commonly used in plastic molding include aluminum and steel.

-

4. Plastic Mold Manufacturing Processes

A. Mold Design

The mold design and specifications play a critical role in the quality of the final product, with the design influencing parameters such as the injection pressure, temperature, and cooling speed.

B. Mold Fabrication

This involves the actual fabrication of the mold, which can be made of metallic or non-metallic materials depending on factors such as cycle times, structural demands, and material limitations.

C. Injection Molding

Injection molding is the process of injecting molten plastic material into the mold, where it cools and hardens to form the desired product shape.

D. Post-Molding Operations

Post-molding operations such as trimming, sanding, or polishing are necessary to remove excess materials and improve the surface finish and overall quality of the final product.

-

5. Best Practices for Working with Plastic Mold Manufacturers

A. Finding the Right Manufacturer

It is important to consider factors such as quality standards, experience, certifications, pricing, and customer service when selecting a plastic mold manufacturer.

B. Collaborating with the Manufacturer

Collaborating with the manufacturer at every step of the process is essential to ensure that the final product meets the required specifications and timelines.

C. Quality Control and Testing

Quality control and testing are necessary to ensure that the final product meets the required quality standards, specifications, and regulations.

D. Communication and Transparency

Regular communication with the manufacturer is essential to ensure that the project progresses smoothly and that potential issues are addressed promptly.

-

6. Applications of Plastic Molded Products

A. Automotive Industry

Plastic molds are widely used in the automotive industry for producing parts such as dashboards, bumpers, and electrical components.

B. Medical Industry

Precision plastic mold manufacturing and engineering is essential for medical devices, implants, and tools requiring high dimensional accuracy and strict regulatory compliance.

C. Packaging Industry

Plastic molds are popular in the packaging industry for manufacturing products such as bottles, jars, and containers.

D. Consumer Goods Industry

Plastic molds are widely used in the creation of everyday items such as toys, kitchenware, and electrical appliances.

E. Electronics Industry

Plastic molds are prevalent in the electronics industry for creating parts such as television casings, keyboards, and computer hardware.

-

7. Trends and Innovations in Plastic Mold Manufacturing

A. Sustainable Materials and Practices

Sustainability is becoming an essential factor in plastic mold manufacturing, with a focus on using eco-friendly materials and production processes that minimize waste and reduce the carbon footprint.

B. Industry 4.0 Technologies

Industry 4.0 technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing are being integrated into plastic mold manufacturing to improve efficiency, quality, and productivity.

C. Advanced Mold Design and Fabrication Techniques

Advanced mold design and fabrication techniques such as additive manufacturing and nanotechnology are being explored to create more complex shapes and structures with higher precision and accuracy.

If you need about Plastic Injection Molding Services,You can click on the V1 Prototype website to find it:16 Years Foucus On Plastic Injection Mold Manufacturing, Molding Products Mainly In Automotive, Electronics, Appliance, Medical, Housewares Industries.

-

8. Challenges and Solutions in Plastic Mold Manufacturing

A. Cost and Time Constraints

Plastic mold manufacturing can be a costly and time-consuming process due to factors such as material selection, tooling, and production setup. Employing computer-aided design and manufacturing (CAD/CAM) and smart manufacturing technologies can help reduce these constraints.

B. Material Selection and Performance

Material selection and performance can pose significant challenges in plastic mold manufacturing, especially in applications requiring high temperatures, pressure, or other environmental factors. Advanced materials and coatings can help address some of these challenges.

C. Design and Quality Control

Achieving the desired quality standards and specifications can be challenging due to factors such as part geometry, mold design, and process variability. Employing tools such as statistical process control (SPC) and finite element analysis (FEA) can help improve the design and quality control processes.

D. Adaptation to Technological Advances

As plastic mold manufacturing continually evolves, manufacturers must adapt to the latest technological advances to remain competitive and meet changing market demands. Continuous training and investment in cutting-edge technologies can help manufacturers stay ahead of the curve.

-

9. Conclusion and Future Outlook

A. Summary of Key Points

Plastic mold manufacturing is a critical component of modern manufacturing that offers an efficient and cost-effective way to produce high-quality products with complex shapes and structures. With the integration of Industry 4.0 technologies and sustainable practices, the future of plastic mold manufacturing looks promising.

B. Future of Plastic Mold Manufacturing

The future of plastic mold manufacturing is likely to involve a focus on sustainability, integrated manufacturing, and advanced materials and processes. The industry is poised to leverage the latest technologies and innovations to improve efficiency, quality, and productivity.

C. Resources for Further Learning

Industry associations, academic research, and technical publications are excellent resources for learning about the latest developments in plastic mold manufacturing and best practices. Keeping up with current trends and advances can help manufacturers stay competitive and produce high-quality products that meet changing market demands.