Table of Contents:

- Introduction

- Growth of China Plastic Injection Mold Industry

- Innovations in China Plastic Injection Mold Industry

- Applications of China Plastic Injection Mold Industry

- China Plastic Injection Mold Industry Supply Chain

- Challenges for China Plastic Injection Mold Industry

- Future Directions for China Plastic Injection Mold Industry

- Conclusion

-

1. Introduction

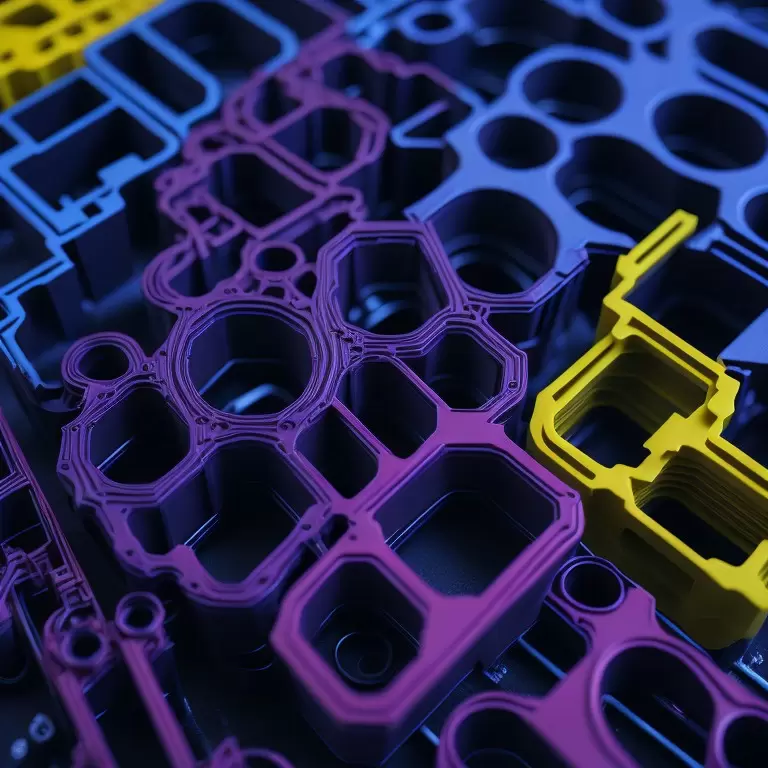

The plastic injection mold industry in China is an essential component of the country’s manufacturing sector. It involves the production of precision molds used to create plastic items ranging from household appliances to automotive components. Plastic injection molding is widely used in the production of consumer goods and industrial products due to its versatility, low cost, and high efficiency.

Definition of China Plastic Injection Mold Industry:

The China plastic injection mold industry involves the manufacturing of molds used for the production of plastic objects. It is a vital sector of the country’s manufacturing industry, employing millions of people and contributing significantly to the national economy.

Importance of China Plastic Injection Mold Industry:

The China plastic injection mold industry plays a crucial role in the country’s economy, with a focus on meeting the growing demand for plastic products in the domestic and international markets. The industry provides employment opportunities, export revenues and contributes to the country’s Gross Domestic Product (GDP). Additionally, the industry’s introduction of advanced technologies and machinery contributes to the modernization of the manufacturing sector in China, allowing domestic manufacturers to compete effectively with foreign counterparts.

-

2. Growth of China Plastic Injection Mold Industry

The plastic injection mold industry in China has experienced significant growth over the past few decades, making it one of the largest markets globally. The country’s manufacturing sector has a reputation for producing high-quality products at a low cost, which has made China an attractive destination for global companies to outsource their manufacturing needs. The growth of the China plastic injection mold industry has also been driven by advancements in technology, increasing demand for plastic products, and the availability of skilled labor.

Historical Development of China Plastic Injection Mold Industry:

The plastic injection mold industry in China has its roots in the 1950s when the country’s government began investing in the manufacturing sector. However, it was not until the 1980s that China’s plastic injection mold industry started to gain momentum. The country’s economic reforms during this period allowed more foreign companies to invest in the country, leading to the transfer of advanced manufacturing technologies and know-how.

Current State of China Plastic Injection Mold Industry:

Today, China is the largest market for plastic injection molds globally, with a market share of approximately 40%. The industry is dominated by small and medium enterprises, with over 70% of plastic injection mold manufacturers employing less than 50 people. Currently, the industry is facing challenges, such as rising labor costs, increasing competition, and environmental concerns.

Trends in China Plastic Injection Mold Industry:

The plastic injection mold industry in China is witnessing several trends, including rising demand for high-precision molds, increasing investment in research and development, and the adoption of Industry 4.0 technologies to improve manufacturing processes’ efficiency. Additionally, the industry is innovating new materials, such as biodegradable plastics, to meet increasing sustainability concerns.

If you need about Plastic Injection Molding Services,You can click on the V1 Prototype website to find it. V1 Prototype have 16 Years Foucus On Plastic Injection Mold Manufacturing, Molding Products Mainly In Automotive, Electronics, Appliance, Medical, Housewares Industries.

-

3. Innovations in China Plastic Injection Mold Industry

Advanced Technologies in China Plastic Injection Mold Industry:

The China plastic injection mold industry has been investing in advanced technologies such as additive manufacturing, simulation software, and artificial intelligence to enhance their manufacturing capabilities. Advancement in 3D printing technology helps to reduce lead times and costs in designing and prototyping of new products.

New Materials Used in China Plastic Injection Mold Industry:

The use of new materials in the China plastic injection mold industry has significantly expanded the industry’s production capabilities. New materials such as biodegradable plastics, lightweight composites, and high-temperature thermoplastics are being developed to meet challenging demands from electronics, automotive, and aerospace industries.

Customization and Personalization of China Plastic Injection Mold Industry:

Customization and personalization of plastic injection molding products are emerging trends in the industry. Advances in 3D printing technology and customization software allow manufacturers to offer personalized products that meet specific customer requirements.

-

4. Applications of China Plastic Injection Mold Industry

Key End-Use Applications of China Plastic Injection Mold Industry:

The China plastic injection mold industry’s primary end-use applications are consumer goods such as packaging, toys, and household appliances. Automotive and electronics industries are quickly expanding digitization trends, using plastic injection molding in product development, and reducing the weight of the products.

China Plastic Injection Mold Industry in the Global Market:

China is the largest market in the world for the plastic injection mold industry, with a market share of approximately 40%. The country’s low-cost manufacturing capabilities and skilled labor force have made China an attractive destination for global companies to outsource their manufacturing needs.

Emerging Markets for China Plastic Injection Mold Industry:

The rapidly growing automotive, electronics, and medical industries worldwide are opening up new markets for the China plastic injection mold industry. The demand for high-quality plastic components for critical medical devices and sophisticated automotive engine components creates new opportunities for the plastic injection mold industry in China.

-

5. China Plastic Injection Mold Industry Supply Chain

Major Players in China Plastic Injection Mold Industry:

The China plastic injection mold industry is fragmented, with several manufacturers operating in the market. Large multinational companies and local manufacturers are essential players in the industry.

Suppliers of Raw Materials and Equipment for China Plastic Injection Mold Industry:

The China plastic injection mold industry is dependent on suppliers of raw materials such as plastics, dyes, and inks, and equipment such as injection molding machines.

Regulatory Framework for China Plastic Injection Mold Industry:

The China plastic injection mold industry is highly regulated. The industry must comply with regulations on product safety, environmental protection, and labor laws.

-

6. Challenges for China Plastic Injection Mold Industry

Environmental and Sustainability Concerns:

The China plastic injection mold industry is facing increased pressure to adopt sustainable manufacturing practices. Waste reduction, energy efficiency, and eco-friendly packaging are emerging priorities in the industry.

Increased Competition from Emerging Markets:

The China plastic injection mold industry faces increased competition from emerging markets, such as Southeast Asia, India, and Brazil. These emerging markets have lower manufacturing costs and are quickly developing their manufacturing capabilities.

Intellectual Property Rights Issues in China Plastic Injection Mold Industry:

Intellectual property protection is challenging in the China plastic injection mold industry, leading to issues like piracy and counterfeit products. It is important to promote and protect intellectual property to maintain product quality and respect copyrights laws.

-

7. Future Directions for China Plastic Injection Mold Industry

Emerging Technologies and Trends:

The China plastic injection mold industry is expected to continue investing in emerging technologies such as Industry 4.0, automation, and artificial intelligence, enhancing manufacturing productivity, and cost-effectiveness.

Opportunities and Challenges in China Plastic Injection Mold Industry:

The China plastic injection mold industry’s future is bright, with abundant opportunities for development and expansion. Technological advancements will help the industry maintain its competitive edge. The challenges include environmental concerns, intellectual property rights issues, and regulatory compliance.

Strategic Recommendations for China Plastic Injection Mold Industry:

To succeed in the plastic injection mold industry in China, manufacturers should focus on investing in new technologies to improve their manufacturing capabilities, collaborating with other firms to develop new products, and improving their environmental sustainability policies. In addition, conducting regular audits on the supply chain and adapting to market changes are other critical strategies that manufacturers can adopt to stay competitive.

-

8. Conclusion

The plastic injection mold industry in China is a vital sector of the country’s manufacturing industry. Technological advancements and high-quality production capabilities have made China the dominant market in the industry. With increasing demand from emerging markets and growing attention to environmental sustainability, the industry needs to continue to innovate and adapt. The strategic recommendations provided can help manufacturers stay competitive and succeed in the ever-changing plastic injection mold industry in China.