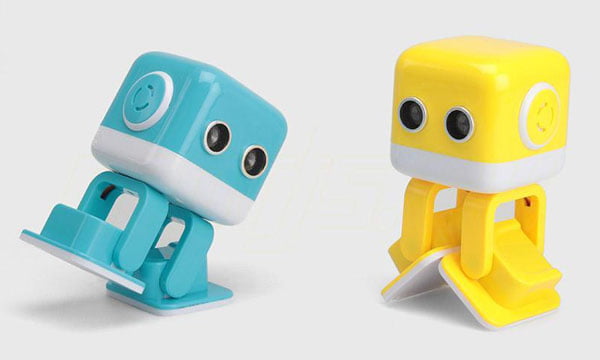

The Role of Rapid Prototyping in Intelligent Robot Development

As robots become increasingly intelligent and autonomous, the process of researching, designing, and testing new models is complex with many variables to consider. One technology that has proven invaluable for robotics engineers is rapid prototyping. By fabricating functional prototypes in a fraction of the time required by traditional methods, it allows for more iterative testing and refinement throughout development. This speeds up the design cycle while improving end product quality and performance.Rapid Prototyping Benefits the Design Phase

When conceptualizing new robotic systems and mechanisms, rapid prototyping empowers researchers to visualize and evaluate concepts quickly. Physical prototypes facilitate exploring diverse form factors and range of motion without extensive modeling or machining. Teams can test prototype robots performing target tasks to validate hypothesized designs and behaviors in the real world. Issues are caught earlier, focusing precious research dollars on viable solutions. Iterating prototypes based on test data yields robust designs ready for refinement.Speeding Development with Functional Prototypes

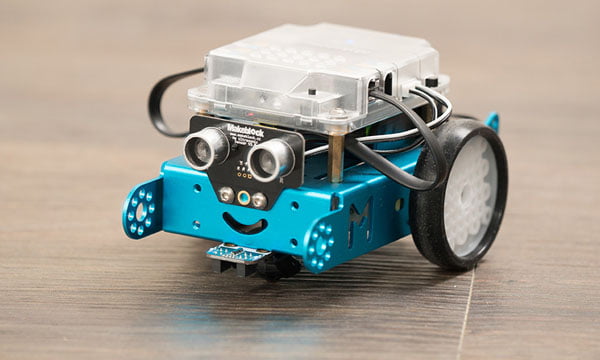

In robotics development, rapid prototyping translates virtual components into working prototypes for integrated evaluation. Developers produce functional early versions to test hardware and software integration for target tasks. Prototyping individual robotic modules brings swift consideration of alternative actuators, sensors or algorithms through construction and direct assessment. Simulating full system operation with prototypes finds interface problems that could stall later product cycles. Iterating prototypes as understanding improves leads to well-designed systems.Thorough Prototyping Allows Robust Testing

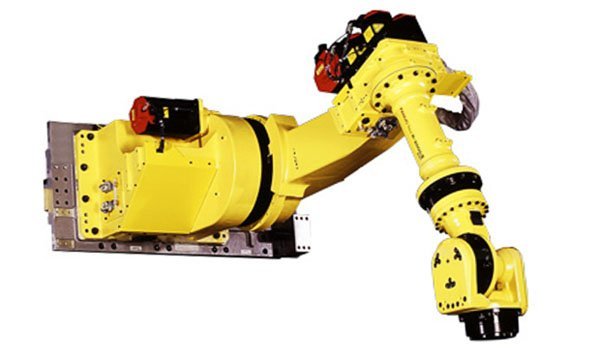

Testers applying rapid prototyping conduct thorough evaluations simulating real-world robot deployment. Repeated durability prototyping yields designs surviving rigorous testing cycles. Prototypes undergo assessments in relevant environments, e.g. indoor, outdoor or hazardous locations. Testing prototypes facilitates evaluating full range of performance factors like accuracy, speed, power usage and safety protocols. Edge case behavior is discovered through experimental conditions prototypes endure, resulting in robust products.Rapid Technologies for Robotics Prototyping

Common rapid prototyping approaches benefiting robotics include: 3D printing produces complex mechanical prototypes with moving parts for form and function tests. Multi-material 3D printing allows evaluating components in target materials. CNC machining produces stronger prototypes for performance testing robots handling physical tasks. Injection molding of 3D-printed molds facilitates durability testing. Laser cutting enables swift assembly of prototypes to evaluate mechanical designs. Together, these rapid prototyping methods accelerate all robot development stages.accelerating Intelligent Machine Learning Through Prototyping

As robot intelligence increasingly depends on machine learning techniques, rapid prototyping assumes even greater significance. Researchers can leverage rapid prototyping to: evaluate diverse neural network architectures via experimentation with prototype robots in relevant contexts. Test and refine computer vision, navigation and grasp algorithms through iterative prototype development and evaluation. Swiftly produce small prototype populations for genetic and evolutionary algorithm training featuring robotic phenotypes with varied characteristics. Accelerate the training and validation of deep reinforcement learning agents through rapid deployment of embodied prototype robots. In these ways, rapid prototyping fuels progress in machine intelligence for robotics applications.Driving the Future of Autonomous Systems

By allowing robotic prototypes to be developed, tested and improved at an unprecedented pace, rapid prototyping acts as a key enabler of ever more advanced autonomous robots. Prototypes lay the groundwork for productive collaboration across multidisciplinary teams. They demonstrate feasibility and validate technical approaches to attract further research and development investment. Rapid prototyping empowers robotics innovators to explore bold new concepts and push the boundaries of what’s possible through an iterative process. This promises to accelerate progress in autonomous mobile manipulation, human-robot interaction, precision industrial automation and beyond. Overall, rapid prototyping fuels the continued rise of intelligent robotics. In conclusion, rapid prototyping has transformed robotics product development by facilitating evaluation of concepts, testing of components, system integration and full product assessment through iterative prototype iterations. This compressed design-build-test cycle translates to higher quality autonomous systems reaching the market faster. Rapid prototyping continues powering advances across the intelligent robotics field by enabling exploration and validation of ambitious new ideas.Professional rapid prototyping services

3D Printing Service: We offer high-quality, fast and affordable 3D printing solutions for various industries and applications. Contact us today for a free quote.

Precision CNC Machining service provides high-quality custom parts with tight tolerances and fast turnaround times. Contact us for a free quote today.

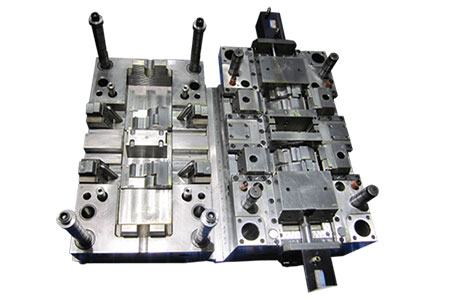

Rapid tooling service is a process that uses 3D printing or CNC machining to create custom molds or prototypes in a short time. It is suitable for low-volume production or testing purposes.

Plastic & Metal Batch Production

Plastic mold making is a process of manufacturing plastic products that involves creating a physical mold of a designed shape, using it to produce plastic products with the desired shape and size.

Plastic injection molding service is a process of producing plastic parts by injecting molten plastic into a mold. It is fast, precise and cost-effective.

Metal die casting service is a process of creating metal parts by injecting molten metal into a mold. It offers high precision, durability and cost-effectiveness for various industries.

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: info@v-1.com

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850