Introduction

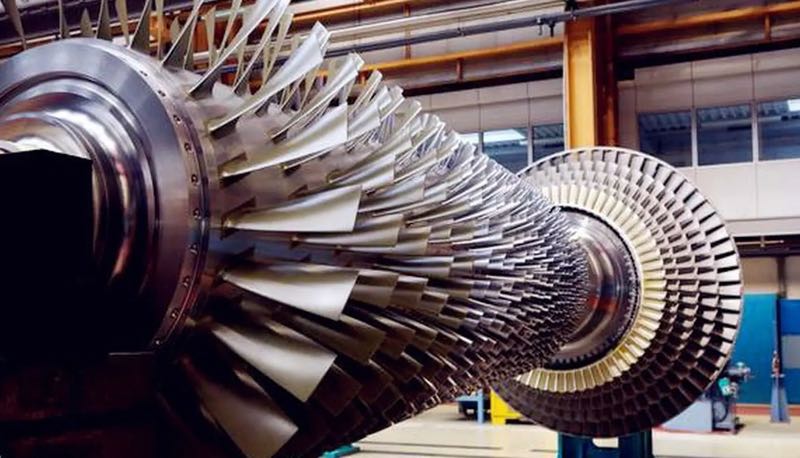

In recent years, 3D printing, also known as additive manufacturing, has emerged as a disruptive technology with the potential to transform various industries. One area where 3D printing has made significant strides is gas turbine manufacturing. Gas turbines are critical components used in power generation, aviation, and industrial applications. The adoption of 3D printing in gas turbine manufacturing has revolutionized the industry, allowing China to accelerate its technological advancements and assert its position as a global player in the gas turbine market. In this blog post, we will explore how 3D printing has enabled China's gas turbine manufacturing technology to take off, the benefits it offers, and the future implications for the energy sector.

The Rise of 3D Printing in Gas Turbine Manufacturing

1. Overcoming Traditional Manufacturing Challenges

Traditionally, gas turbine components were manufactured using conventional methods such as casting, forging, and milling. These methods often resulted in time-consuming and costly processes, especially when dealing with complex geometries. 3D printing technology has revolutionized gas turbine manufacturing by offering a more efficient and cost-effective alternative.

2. Design Freedom and Complex Geometry

One of the significant advantages of 3D printing is the design freedom it offers. Gas turbine components with intricate geometries and internal cooling channels can be easily fabricated through additive manufacturing. This flexibility allows engineers to optimize designs for improved efficiency and performance.

3. Lightweighting and Improved Efficiency

The ability to create complex lattice structures and topology-optimized components using 3D printing has led to significant weight reductions in gas turbine parts. Lighter components result in reduced rotational inertia and improved overall efficiency, leading to enhanced power generation and fuel economy.

4. Rapid Prototyping and Iterative Design

3D printing enables rapid prototyping, allowing engineers to quickly test and validate new designs. This iterative design process accelerates product development cycles and reduces time to market for new gas turbine models.

3D Printing Materials for Gas Turbine Manufacturing

1. High-Temperature Alloys

Gas turbines operate under extreme conditions with high temperatures and pressures. Advanced high-temperature alloys, such as nickel-based superalloys and titanium alloys, are commonly used in 3D printing for gas turbine components. These materials offer excellent mechanical properties and resistance to thermal degradation.

2. Ceramic Matrix Composites (CMCs)

CMCs are a class of materials that combine ceramics and fibers to create lightweight and high-strength components. 3D printing allows for the precise fabrication of CMC components, making them ideal for applications in gas turbines where thermal resistance and mechanical integrity are essential.

3. Metal Matrix Composites (MMCs)

MMCs are materials composed of a metal matrix reinforced with particles or fibers. 3D printing enables the production of MMC components with tailored properties, providing superior performance in gas turbine applications.

4. Coatings and Repairs

3D printing is not only used for manufacturing new gas turbine components but also for repair and maintenance. Coatings, such as thermal barrier coatings (TBCs), can be applied using 3D printing to protect and enhance the durability of gas turbine parts.

Advancements in China's Gas Turbine Manufacturing

1. State-of-the-Art Facilities and Investments

China has made significant investments in research and development of 3D printing technology for gas turbine manufacturing. State-of-the-art facilities equipped with advanced 3D printers and expertise in material science have been established to drive innovation and propel the country's gas turbine industry forward.

2. Collaborations and Partnerships

China's gas turbine manufacturers have forged collaborations and partnerships with leading 3D printing companies and research institutions globally. These collaborations facilitate the exchange of knowledge, technology, and best practices, fostering the growth of the gas turbine industry in China.

3. Customization and Localization

The adoption of 3D printing in gas turbine manufacturing allows for greater customization of components to meet specific performance requirements. This localization of production reduces reliance on foreign suppliers and strengthens China's position as a self-sufficient and competitive player in the global gas turbine market.

Frequently Asked Questions

- How does 3D printing improve gas turbine efficiency? 3D printing enables the creation of lightweight and complex components with optimized designs. These improvements lead to reduced rotational inertia and enhanced efficiency, resulting in improved power generation and fuel economy for gas turbines.

- What materials are commonly used in 3D printing for gas turbines? High-temperature alloys, such as nickel-based superalloys and titanium alloys, are commonly used in 3D printing for gas turbine components. Ceramic matrix composites (CMCs) and metal matrix composites (MMCs) are also utilized for their high strength and thermal resistance.

- What are the key advantages of using 3D printing in gas turbine manufacturing? The key advantages of 3D printing in gas turbine manufacturing include design freedom for complex geometries, rapid prototyping for iterative design, lightweighting for improved efficiency, and the ability to use advanced materials like high-temperature alloys and composites.

- How does China's adoption of 3D printing impact the global gas turbine market? China's adoption of 3D printing in gas turbine manufacturing has allowed the country to accelerate its technological advancements and assert its position as a global player in the gas turbine market. With investments in research, state-of-the-art facilities, and collaborations with international partners, China's gas turbine industry is poised for significant growth and competitiveness on the global stage.

Conclusion

3D printing has undoubtedly revolutionized gas turbine manufacturing, allowing for greater efficiency, improved performance, and enhanced design possibilities. In China, the adoption of 3D printing in the gas turbine industry has accelerated technological advancements and strengthened the country's position as a major player in the global market. With state-of-the-art facilities, investments in research, and collaborations with international partners, China's gas turbine manufacturing technology is taking off, propelling the nation towards a more sustainable and competitive future in the energy sector. As the technology continues to evolve, we can expect even greater advancements in gas turbine manufacturing, leading to more efficient and eco-friendly power generation solutions for the world.

3D printing technology, due to its unique principle of layered forming, allows simple and complex forms to be treated almost equally. Just need to have 3D modeling scheme, suitable raw materials and 3D additive manufacturing instruments, you can immediately print parts; because of dumping the mold, so you can use a cheaper price, manufacturing the traditional mold factory can not be manufactured out of the design; if the design subsequently occurred to modify, just modify the design 3D modeling scheme, and print again; 3D printed parts appear damaged, and can even print directly at the breakage repair. So 3D printing on industrial manufacturing disruptive visible. After more than thirty years of development, 3D printing has long been out of the ivory tower and out of the self-indulgence of geeks. Open a treasure, search for "3D printing", from keychains to ice cream, there is always one to meet your next Tanabata's stocking needs.

But the real pursuit of industrial manufacturing, should be the so-called "big sound, big elephant invisible". The great man of chivalry, for the country and the people, even if there are a thousand pounds of power, hidden but not issued. Truly worthy of praise a thousand pieces of 3D printing, but also when the resounding metal 3D printing. Under the mainstream laser sintering technology, parts are printed and shaped after thousands of times of sintering, and a thousand hammers are sharpened into a sword.

3D printing - to meet the precision requirements of modern industry

Known as the "crown jewel of manufacturing" of the gas turbine to date has been developed for more than half a century, want to continue to progress, requiring near-peak technical ability and imagination. In the process of climbing to the top, 3D printing technology can be said to have emerged to make up for the limitations of traditional manufacturing methods. For example, the leading combustion engine - H-class combustion engine, turbine initial temperature of 1500 degrees Celsius, combined cycle efficiency of 62.22%, extremely high flexibility, ultra-low emissions, the culmination of a century of human industrial civilization, the essence of 3D additive manufacturing.

One of the core components of the GE 9HA gas turbine - the fuel nozzle and premixer of the combustion chamber - uses 3D additive manufacturing processes, and the microporous premixing technology ensures the effective performance of GE's low-NOx combustion technology DLN2.6e. Combined with many equally cutting-edge technologies, the 9HA unit at the Bouchon power plant in France finally achieved the Guinness World Record breaking combined cycle efficiency of 62.22%. Guinness World Record combined cycle efficiency - 62.22%.

This is how the "big sound and the big elephant are invisible".

3D printing can actually achieve how much change? Let's take the fuel nozzle in the GE9HA combustion engine as an example. The dense inlet holes allow the 9HA to achieve micro-hole premixing and full premixing combustion in the low-NOx combustion technology DLN2.6E, which ensures that the fuel and air are mixed in a better ratio to achieve a full premixing combustion mode for the start-stop process, without diffusion flame, to meet the ultra-low NOx emissions (only 25ppm under the lowest load to 30% of the operating conditions NOx emissions), supporting rapid load increase and decrease of the combustion engine.

3D printing - the world's most advanced combustion engine

The H-class combustion engine is huge, GE's 9HA combustion engine is about 12 meters high (about four floors) and weighs about 400 tons (about two blue whales), and in actual use, the combustion engine itself will have many "auxiliary machines" to help fully recover the waste heat of exhaust gases, etc. In addition to the large size, many parts, and the need for "auxiliary engine" compatibility, the power generation industry also expects the combustion engine to work 24x7, while meeting increasingly stringent environmental regulations. All of this requires the design and manufacture of H-class combustion turbines to be infinitely close to perfection - with precision tolerances of up to a few tens of microns for the core components of the gas turbine.

One of the reasons why the GE9HA turbine is the most efficient gas turbine in the world (there is no one) is 3D additive manufacturing.

Specifically, the full application of 3D printing technology on key components was able to help increase the output of the GE9HA gas turbine by 1% compared to traditional manufacturing methods. GE's 9HA unit at the Bouchon power plant in France can supply the electricity needs of about 680,000 French households, which means that these two components will bring light to an additional 6,800 households, while the original energy consumption remains unchanged.