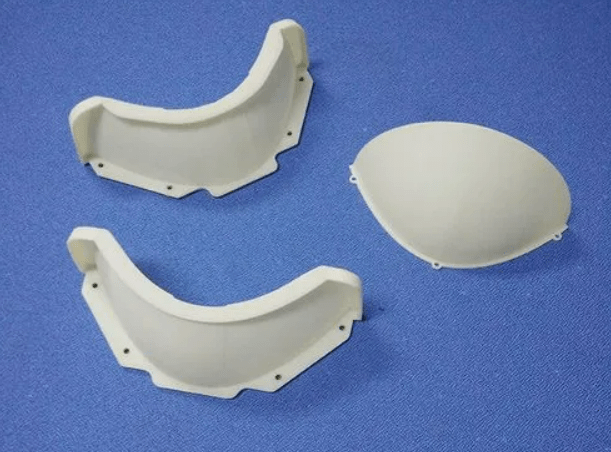

During prototype proofing, some products can be made either by CNC processing or by 3D printing. Because CNC processing is relatively complicated and the workload is larger than 3D printing in theory, most customers take it for granted that CNC processing is more expensive than 3D printing. Is this the case?

However, it is cost-effective to use CNC processing for hand boards with simple structure and large volume. 3D printing is mainly charged by weight. For small products with complex structures and processes, 3D printing may be more expensive.

Therefore, when 3D printing and CNC processing are used as a prototype, it is uncertain which price is cheaper. It needs to be analyzed according to the actual situation.

V1 precision model has accumulated rich experience in both CNC prototype production and 3D printing prototype. If you have the demand for prototype production, our technicians will provide you with the most professional suggestions, recommend the most cost-effective processing methods, and maximize the control of production costs.

When it comes to creating physical prototypes, 3D Printing and CNC Processing are two of the most popular methods. Both these methods have their own set of advantages and disadvantages. In this blog post, we will discuss which method is more cost-effective, taking into consideration various factors.

Factors Affecting Cost-Effectiveness

The cost-effectiveness of a prototype method depends on several factors, including:

1. Complexity of Design

If the design is complex, 3D Printing might be more cost-effective as the process is much easier and quicker than CNC Processing. Complex designs take longer to process, thus increasing the overall cost.

2. Material Type

The type of material used for prototyping can significantly impact its cost-effectiveness. If the material is readily available and less expensive, it can reduce the cost of both 3D Printing and CNC Processing.

3. Quantity of Prototypes

The quantity of prototypes is also a significant factor. For a small quantity of prototypes, 3D Printing can be more cost-effective. While CNC Processing is more suited for a larger quantity of prototypes, which can reduce the overall cost when printed in bulk.

4. Surface Finish Required

If a particular level of surface finish is required, CNC processing is generally more preferred choice as it offers a higher quality surface finish compared to 3D printing.

Cost-Effectiveness Comparison of 3D Printing and CNC Processing

Both 3D Printing and CNC Processing have their own advantages and disadvantages in terms of cost-effectiveness.

1. 3D Printing

The cost-effectiveness of 3D Printing often depends on various factors such as complexity of design, material type and quantity of prototypes needed. Complex designs take longer to process, which means the overall cost will be higher. The material used for 3D Printing can be relatively expensive, and this can increase the cost per prototype. However, for small quantity prototyping 3D Printing is more cost-effective as it involves less equipment and shorter setup time.

2. CNC Processing

CNC Processing is often used to create a large quantity of prototypes due to its cost-effectiveness. The machine setup cost is higher than 3D Printing, but the cost per prototype is lower, especially when printed in bulk. CNC processing is also suitable for creating parts with complex shapes and high-quality surface finish, which is not possible in 3D Printing.

Answers To Commonly Asked Questions

Is 3D Printing Cheaper than CNC?

The cost of 3D printing is lower than CNC when producing low volume prototypes with intricate designs.

Which is Better CNC or 3D Printing?

The choice of either CNC or 3D printing depends on the design's complexity and the volume of production required. 3D printing excels in producing low volume prototypes with intricate designs, while CNC processing excels in high volume production that requires long-lasting end products with high strength materials.

Advantages of CNC Over 3D Printing

CNC processing offers higher accuracy, better surface finishing, and the ability to work with a wide range of materials in substantial quantities. CNC processing also enables the production of long-lasting end products that can withstand high pressure and extreme temperatures, which is not the case with 3D printing.

Conclusion

In conclusion, the decision to use either 3D Printing or CNC Processing for prototyping depends on the specific requirements of a project. While 3D printing is more suitable for small quantities and simpler designs, CNC processing is more suitable for larger quantities and complex parts. Both methods have advantages and disadvantages in terms of cost-effectiveness, which must be taken into consideration before selecting the appropriate method.