This article explores the advantages of 3D rapid prototyping service. Learn how 3D printing has revolutionized the traditional prototyping process, allowing businesses to save time, money, and effort while quickly bringing new ideas to life.

Table of Contents:

I. Introduction

- Definition of 3D rapid prototyping service

- Overview of 3D printing technology

II. How 3D Rapid Prototyping Service Works

- Steps involved in the rapid prototyping process

- Types of 3D printing technologies

III. Materials Used in 3D Rapid Prototyping Service

- Types of materials used for 3D printing

- Properties of 3D printing materials

IV. Advantages of 3D Rapid Prototyping Service

- Cost savings

- Time efficiency

- Flexibility in design

V. Applications of 3D Rapid Prototyping Service

- Examples of industries using 3D rapid prototyping service

- Applications in product development

VI. Limitations of 3D Rapid Prototyping Service

- Surface finish

- Size limitations

VII. Comparison of 3D Rapid Prototyping Service to Traditional Prototyping

- Differences between 3D rapid prototyping and traditional prototyping

- Advantages of 3D rapid prototyping service over traditional prototyping

VIII. Conclusion

- Future of 3D Rapid Prototyping Service

I. Introduction

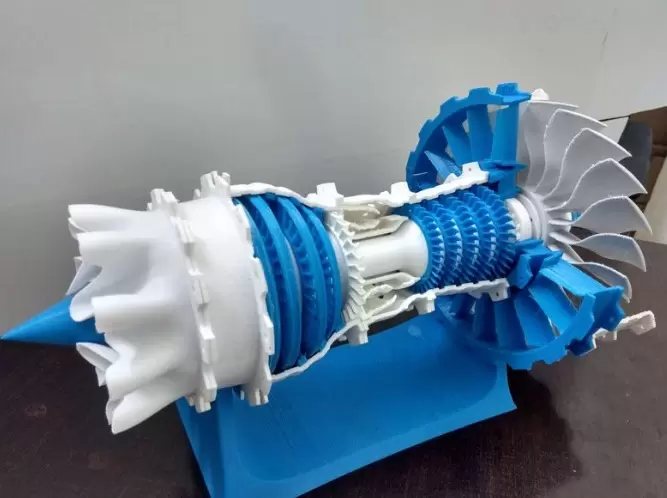

3D rapid prototyping service uses 3D printing technology to quickly create physical prototypes of products, parts or design. This technology has revolutionized the traditional prototyping process by saving time, reducing costs and enhancing design flexibility. In this article, we will explore the technology behind 3D rapid prototyping service, its benefits, and limitations.

II. How 3D Rapid Prototyping Service Works

The process of 3D rapid prototyping service consists of several steps, including designing the CAD file, converting the CAD file to a 3D model, and printing the 3D object. Different 3D printing technologies use different methods to print the object layer by layer, with the most common being Fused Deposition Modeling and Stereolithography.

III. Materials Used in 3D Rapid Prototyping Service

3D printing can use different materials, including plastics, metals, and composites. The choice of material will depend on the final product’s requirements, including its strength, flexibility, and temperature resistance.

IV. Advantages of 3D Rapid Prototyping Service

3D rapid prototyping service offers several benefits over traditional prototyping methods, including cost savings, time efficiency, and flexibility in design. This technology provides an opportunity to alter the design without having to create new tools for every design change required, which also helps businesses to save money during the product development process.

V. Applications of 3D Rapid Prototyping Service

3D rapid prototyping service is used across various industries, including automotive, aerospace, and medical, to create parts, products, and prototypes. It is used for creating customized prosthetics, testing new product designs, and creating accurate models to communicate design intent.

VI. Limitations of 3D Rapid Prototyping Service

The main limitations of 3D rapid prototyping service include surface finish limitations, where parts may not have smooth surfaces or the required accuracy, and size limitations, where larger parts may not be produced on one print.

VII. Comparison of 3D Rapid Prototyping Service to Traditional Prototyping

Compared to traditional prototyping methods, 3D rapid prototyping service offers several advantages such as speed, cost-effectiveness, and flexibility of designs.

VIII. Conclusion

Overall, 3D rapid prototyping service offers multiple benefits to businesses, including cost-effectiveness, design flexibility, and speed of production. As the technology continues to improve, there will be additional benefits companies can gain from it.