Table of Contents:

- Introduction to 5 Axis CNC Machining

- 5 Axis CNC Machining Services: Processes and Techniques

- Advantages of 5 Axis CNC Machining Services

- Applications of 5 Axis CNC Machining Services

- Quality Control in 5 Axis CNC Machining Services

- Choosing a 5 Axis CNC Machining Service Provider

- Challenges in 5 Axis CNC Machining

- Future of 5 Axis CNC Machining Services

- Conclusion

--

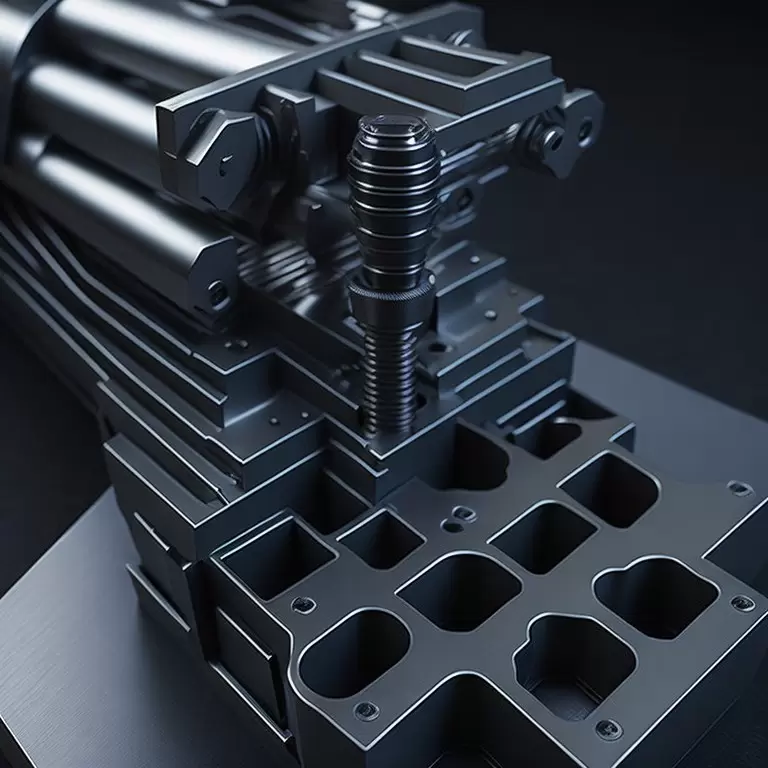

1. Introduction to 5 Axis CNC Machining:

5 Axis CNC machining is a next-generation manufacturing technology that allows for the production of complex parts with high accuracy and precision. This article provides a comprehensive guide to 5 Axis CNC machining services, including processes, techniques, advantages, applications, quality control, challenges, and the future of 5 Axis CNC machining services.

Definition of 5 Axis CNC Machining Services:

5 Axis CNC machining services refer to the process of utilizing advanced multi-axis CNC machines to manufacture intricate parts, even with complex geometries, with high accuracy and precision. This technology can achieve the highest degree of accuracy and precision in the industry.

Importance of 5 Axis CNC Machining Services:

5 Axis CNC machining is essential in various industries, including aerospace, defense, automotive, and medical industries, among others.

-

2. 5 Axis CNC Machining Services: Processes and Techniques:

Definition of 5 Axis CNC Machining:

5 Axis CNC machining is a manufacturing process that utilizes advanced CNC machines to manufacture complex parts with high accuracy and precision.

5 Axis CNC Machines:

5 Axis CNC machines have five axes of motion, which allow for the production of complex parts that cannot be produced with conventional CNC machines.

Programming Techniques:

Programming for 5 Axis CNC machines requires advanced programming techniques such as CAM software, toolpath optimization, and G-code programming.

Materials Used in 5 Axis CNC Machining:

Materials such as aluminum, steel, and titanium, among others, can be used in 5 Axis CNC machining services.

-

3. Advantages of 5 Axis CNC Machining Services:

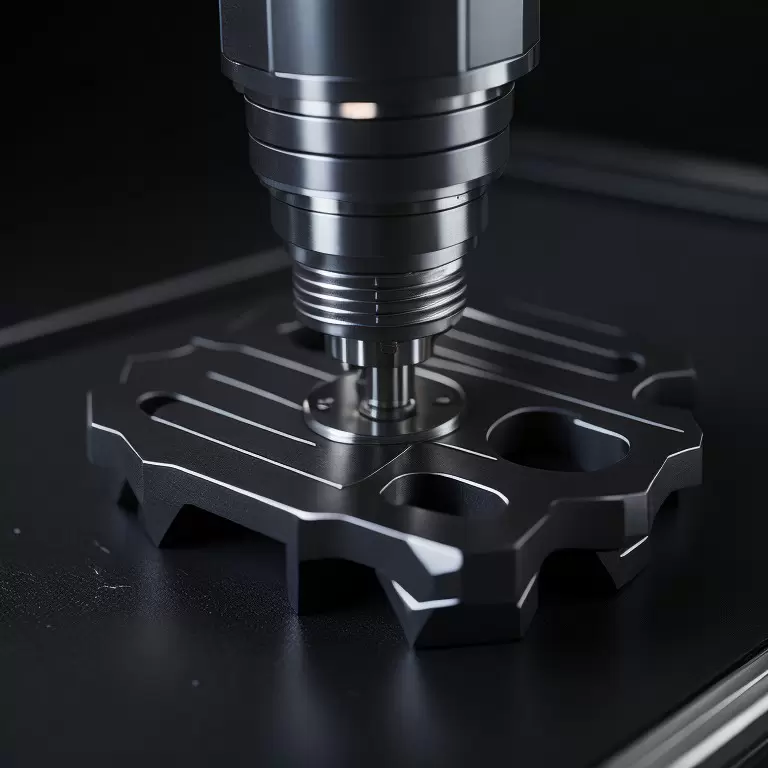

Ability to Produce Complex Parts:

5 Axis CNC machining allows for the production of complex parts with intricate geometries, shapes, and surfaces that cannot be achieved with traditional CNC machines.

Improved Precision and Accuracy:

5 Axis CNC machining ensures high accuracy and precision when producing parts with tight tolerances, which is critical in various industries.

Reduced Setup Time:

5 Axis CNC machines can produce multiple parts without the need for repositioning and reloading the material, leading to a reduction in setup time.

Reduced Production Time:

5 Axis CNC machining allows for the simultaneous cutting of multiple surfaces, leading to a reduction in production time.

-

4. Applications of 5 Axis CNC Machining Services:

5 Axis CNC machining is critical in the aerospace industry for the manufacturing of aircraft engine parts, structural components, and interiors.

5 Axis CNC machining is utilized in the automotive industry for the production of engine parts, transmission components, and suspension systems, among others.

The medical industry uses 5 Axis CNC machining for making various medical devices and implants, including hip implants and surgical instruments, which require high precision and accuracy.

Defense Industry:

The defense industry utilizes 5 Axis CNC machining for the production of complex parts for missiles, fighter jets, and other military hardware.

Consumer Goods Industry:

In the consumer goods industry, 5 Axis CNC machining enables the production of complex components of electronic devices, sporting goods, toys, and luxury products.

-

5. Quality Control in 5 Axis CNC Machining Services:

Inspection and Testing Techniques:

The use of advanced inspection and testing techniques such as CMM, surface roughness testing, and CT scanning are critical in ensuring high-quality production.

Industry Standards and Regulations:

The industry must adhere to industry standards and regulations such as ISO 9001:2015, AS9100D for aerospace, and FDA regulations.

-

6. Choosing a 5 Axis CNC Machining Service Provider:

Factors to Consider:

Choosing a 5 Axis CNC machining service provider requires careful consideration of factors, including experience, expertise, certifications, and equipment capacity.

Types of 5 Axis Machining Companies:

Various types of 5 Axis machining service companies include prototype manufacturers, custom manufacturers, and production manufacturers.

Communication and Collaboration:

Effective communication and collaboration between the manufacturer and customer are essential in ensuring high-quality production and timely delivery.

If you need about 5 Axis CNC Machining Services,You can click on the V1 Prototype website to find it:5 Axis CNC Machining Services Allow For Bespoke Parts With Extreme Multi-Axis Complexity To Be Machined On Time And To Budget.

-

7. Challenges in 5 Axis CNC Machining:

Common Issues and Solutions:

Like any other manufacturing process, 5 Axis CNC machining presents challenges such as technical issues, limited material selection, and high complexity. Solutions include software optimization, advanced toolpath programming, and using innovative manufacturing techniques.

Environmental and Sustainability Concerns:

The industry must adopt sustainable materials and manufacturing practices to reduce carbon footprint, waste, and pollution.

-

8. Future of 5 Axis CNC Machining Services:

Advanced Technologies:

The future of 5 Axis CNC machining services is likely to witness the development of advanced technologies, such as internet-ready machines, artificial intelligence, and machine learning.

Emerging Trends and Opportunities:

Emerging trends in the industry include the adoption of sustainable manufacturing practices, the use of advanced inspection and testing techniques, and the growing demand for aircraft and automotive parts.

-

9. Conclusion:

5 Axis CNC machining services are a critical tool in modern manufacturing technology that enables the production of complex parts with high precision and accuracy. By adhering to industry standards and regulations, choosing the right service provider, and applying sustainable manufacturing practices, manufacturers can ensure high-quality production and maintain a competitive edge in their respective industries. The future of 5 Axis CNC machining services is promising, with the emergence of new technologies and trends that will allow for continued innovation and growth.

In conclusion, 5 Axis CNC machining services offer numerous advantages to various industries, including aerospace, automotive, and medical industries. The use of advanced technologies and programming techniques enables manufacturers to produce complex parts with high accuracy and precision. Quality control measures, adherence to regulations, and sustainability practices are critical in ensuring high-quality production. The future of 5 Axis CNC machining services looks bright, with the emergence of new technologies and trends that will enable continued innovation and growth in the industry.