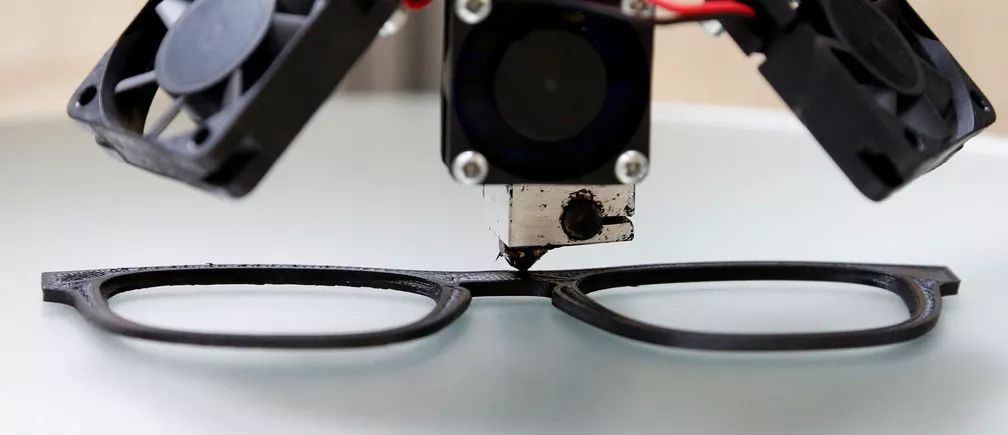

3D printing is a technology that allows the creation of physical objects from digital models by depositing layers of material on top of each other. 3D printing has the potential to revolutionize the way we produce and consume goods, as it enables customization, decentralization, and innovation. According to some experts, 3D printing could account for 50% of manufactured goods by 2060, as more industries adopt this technology and more materials become available for printing. This could have profound implications for the economy, the environment, and society, as 3D printing could reduce waste, transportation costs, and carbon emissions, while increasing efficiency, quality, and diversity. 3D printing could also empower individuals and communities to create their own solutions and express their creativity, as well as challenge existing power structures and regulations. 3D printing could therefore reorder the world in ways that we can hardly imagine today.

You fancy a product on the website of some far-flung overseas company, place an online order for it and request some personalised modifications, the other AI sends you a revised design, you print it out on a 3D printer and the product arrives. Everything is done in a matter of minutes.

To the average person, this may still be a long way off. But to the experts at the World Economic Forum, in perhaps another decade or so, it will all become a reality.

E-commerce is making trade easier, while emerging technologies such as 3D printing and AI could disrupt traditional ways of trading. This could change the global map of manufacturing and the way trade is conducted, and has the potential to become a serious political issue, Zvika Krieger, director of technology policy and partnerships at the World Economic Forum, told China Business News.

"Although the impact will not be immediately visible, countries will still need to pay attention early on, especially those with a strong manufacturing and trade focus." Fan Ziyang, head of the Digital Trade Programme at the World Economic Forum's Centre for the Fourth Industrial Revolution, hopes that the media will draw attention to this issue.

The "new trade" era

On 2 July, the latest statistics from the German Federal Industry Association for Information and Communications and New Media (BITKOM), which surveyed 555 German companies, showed that 32% of German companies would use 3D printing technology. 28% in 2018, compared to 20% in 2016.

At the same time, 78% of the companies surveyed believe that 3D printing could have a profound impact on business models and value chains, eight percentage points higher than last year.

At the World Economic Forum's Annual Meeting of New Leaders, 1-3 July, Canada's Minister of Small Business and Export Promotion Ng Fung Yee said, "In the future, technology will have a greater impact on trade than tariffs, with 3D printing technology alone reducing trade in goods by up to 40%; and blockchain will add $3 trillion to international trade by 2030. "

According to a report published by ABN AMRO Bank and Financial Services (ING) in 2017, 50% of manufactured goods could be 3D printed by 2060, and it is certainly possible that this percentage could even be completed earlier than 2040.

Krieger believes that 3D technology could develop even faster than these predictions. "There are still relatively few cases where 3D printing is used, and the relevant infrastructure does not exist at the moment. But I think things could change dramatically in the next 10 to 15 years." Krieger is the first representative of the US government to Silicon Valley.

"Traditional trade involves manufacturing in country A and shipping it to country B for sale, whereas 3D printing is done directly in country B, without the need for imports, and the volume of trade will obviously decrease." Fan Ziyang said. He previously practised law in international trade.

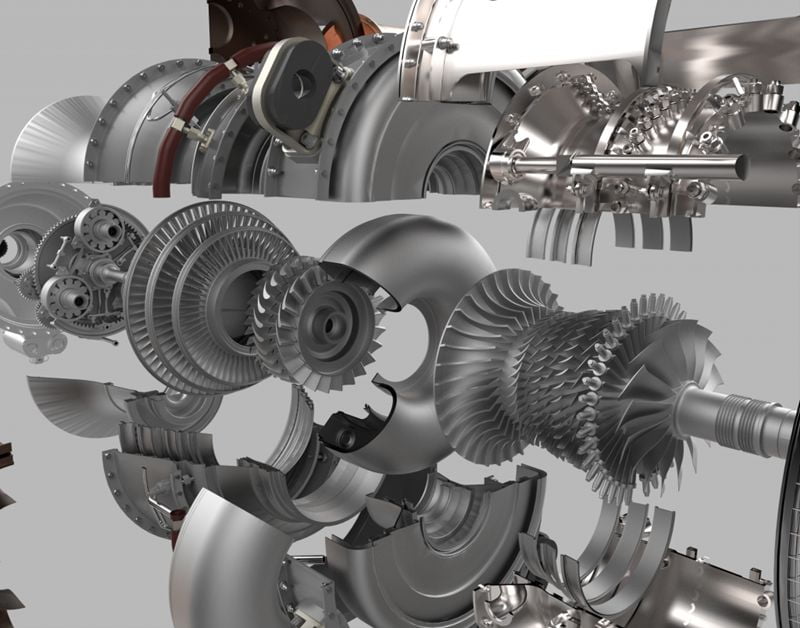

Not only that, but 3D printing will also change the way manufacturing, design and production are done. "For example, with one of GE's engines, the traditional production method involves producing 855 parts and then assembling them. With 3D printing there are only 12 parts, which can have a transformative impact on the supply chain, on suppliers at all levels." Fan Ziyang said the issue has not received widespread attention yet.

Taxation challenges

"Currently, 3D printing is still costly and does not produce everything we need. But in the next 10 years, the cost of 3D printing will come down and more and more products will be able to be produced." Krieger said that the popularity of 3D printing could present many challenges.

As described at the beginning of this article, when products that are imported at sea can be purchased through e-commerce and manufactured in your own home, issues such as customs and intellectual property protection of traditional trade will need to be rethought.

"If what is imported is no longer a physical good, but a design or a code, just a piece of data, how is customs taxed? How will the intellectual property and copyright of non-physical goods be protected and how will the business model of companies change?" Krieger sees these as possible risks associated with technology.

Take customs duties, for example. Yao Jiayuan, head of media operations at the International Union of Customs Colleges, told China Business News that the emergence and popularity of 3D printing technology has indeed presented a whole new challenge to customs regulation and clearance models. "The customs valuation challenge posed by 3D printing technology is that the types of products printed in 3D are not controllable in the customs clearance process and will have a huge impact on goods subject to a sliding scale of duty, regardless of the general levy. In a future where 3D printing technology is massively popular, the key to rationalising valuation and securing customs revenue lies in the differentiated tax management of 3D printers of different sizes and functions, which could be modelled on the differentiation of tax rates for cosmetic products in the mail, with higher tax rates for more functional and specialised printers."