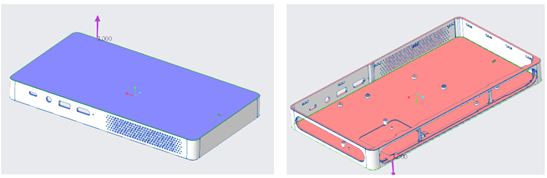

V1 Industrial Internet uses "new aluminum alloy material AD68" new material research and development, professional mold design solutions customized a brand of projector, let me share the product features with you:

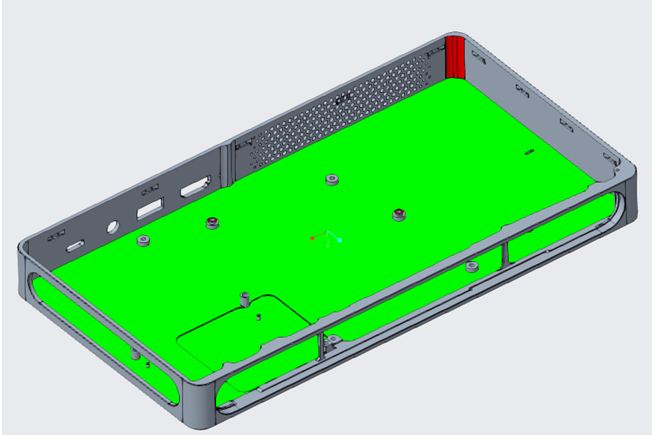

1. We made 1-1.5 degrees draft angle to the white side which is reduced the moldmaking cost by more than 30%.

2. In order to ensure the fluidity of the aluminium oxide, the green side is thickened by 0.5~1MM for better molding and the future surface treatment if required.

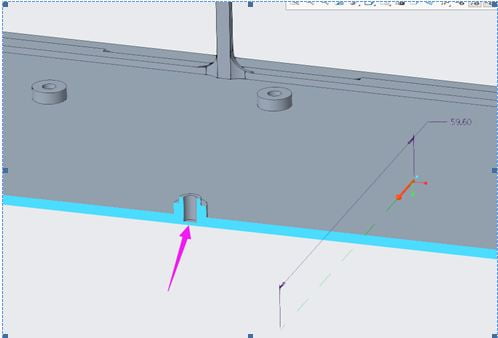

3. All screw holes are guaranteed to have a minimum thickness of 1.0MM at the bottom to prevent the cost increasing caused by the top bubble and CNC machining,thus helping companies to save more than 30% of costs.

4.Finished product picture display

V1 pursues process control, excellence, doing it right once and with zero defects. The reason we use the new aluminium alloy AD68 is it can meet the needs of the current and future market as well as can better help our customers to cast sustainable development products.

Innovation in materials science has always been a driving force behind technological advancements. One such breakthrough is the development of the new aluminum alloy material AD68. This novel material has garnered significant attention across various industries due to its exceptional properties and potential applications. In this blog post, we will delve into the exciting world of AD68 and explore its uses through research case studies.

Understanding AD68 - An Aluminum Alloy of the Future

AD68 is a cutting-edge aluminum alloy that exhibits remarkable strength, lightweight properties, and outstanding corrosion resistance. This unique combination makes it a versatile material with extensive applications across several sectors.

Research Case 1 - Aerospace Industry

The aerospace industry has been quick to embrace AD68 for its potential to revolutionize aircraft design. By using AD68 in the construction of aircraft frames, manufacturers have been able to reduce overall weight without compromising structural integrity. This weight reduction translates to lower fuel consumption and reduced emissions, contributing to a greener and more sustainable aviation sector.

Research Case 2 - Automotive Sector

In the automotive industry, AD68 has emerged as a game-changer for the development of electric and hybrid vehicles. The alloy's lightweight properties significantly enhance the energy efficiency and range of electric cars. Additionally, AD68's high strength ensures improved safety and crash performance, making it an ideal material for constructing vehicle chassis and body components.

Research Case 3 - Renewable Energy

Renewable energy systems, such as solar panels and wind turbines, require materials that can withstand harsh environmental conditions while being cost-effective. AD68 fits the bill perfectly due to its exceptional corrosion resistance and low maintenance requirements. Integrating AD68 components in renewable energy infrastructures enhances their longevity and improves the overall efficiency of clean energy generation.

Research Case 4 - Medical Devices

In the medical field, AD68 has found applications in manufacturing various medical devices, including prosthetics, orthopedic implants, and surgical instruments. The alloy's biocompatibility, coupled with its lightweight nature, makes it an excellent choice for enhancing patient comfort and ensuring better surgical outcomes.

Related Questions:

Q1: How does AD68 compare to traditional aluminum alloys?

A: AD68 outperforms traditional aluminum alloys in terms of strength, corrosion resistance, and lightweight properties. It offers a winning combination that opens up new possibilities for diverse applications.

Q2: What makes AD68 a preferred choice for the aerospace industry?

A: AD68's lightweight characteristics reduce aircraft weight, leading to improved fuel efficiency and reduced emissions. Its robustness ensures structural integrity, making it an excellent fit for the demanding requirements of aerospace engineering.

Q3: How can AD68 contribute to a sustainable future in the automotive sector?

A: By using AD68 in electric and hybrid vehicles, the automotive industry can create energy-efficient and eco-friendly transportation solutions. The material's strength also enhances safety, promoting the development of safer and greener automobiles.

Q4: Are there any challenges associated with AD68 adoption in various industries?

A: While AD68 offers numerous benefits, its relatively higher production costs may pose a challenge to its widespread adoption. However, as research and development progress, the cost-benefit ratio is expected to improve, making AD68 more accessible for different applications.

Conclusion

The advent of the new aluminum alloy material AD68 marks a significant milestone in the world of materials science. As demonstrated by the research case studies, AD68 has the potential to transform multiple industries, from aerospace and automotive to renewable energy and healthcare. As research and innovation continue, we can expect even more exciting applications and breakthroughs, propelling us toward a more sustainable and technologically advanced future.