Table of Contents:

- Introduction

- Working Principles of Rapid Prototyping

- Types of Rapid Prototyping Techniques

- Advantages of Rapid Prototyping

- Applications of Rapid Prototyping

- Limitations of Rapid Prototyping

- Future Outlook of Rapid Prototyping

- Conclusion

-

1.Introduction

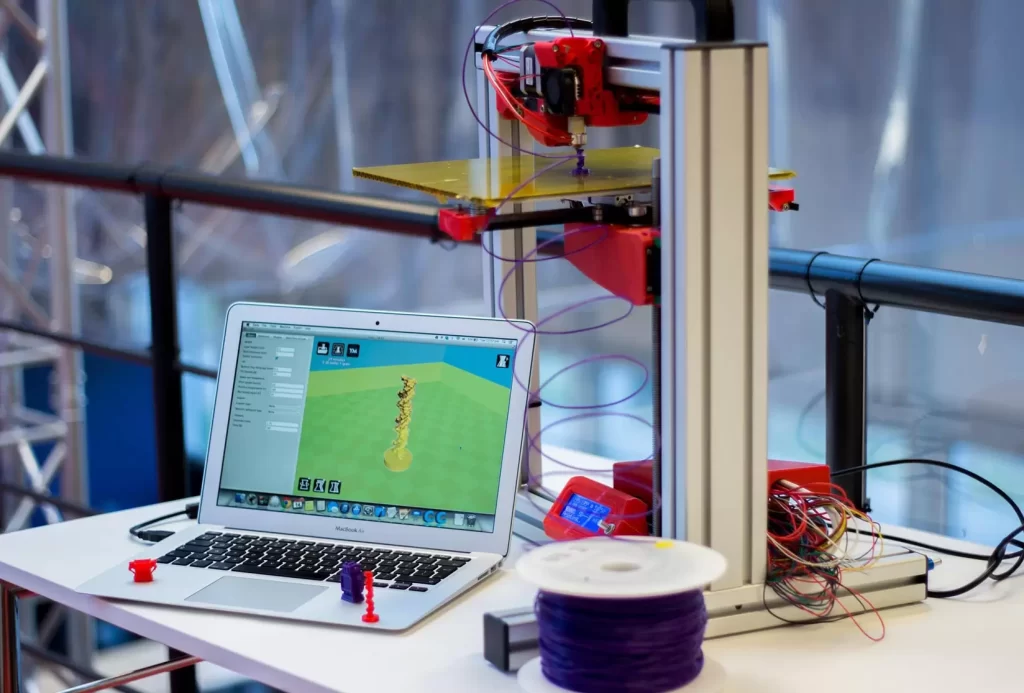

Rapid prototyping is a manufacturing technique that allows for the quick and cost-effective production of physical prototype models for design and product development. It involves the construction of physical prototypes using computer-aided design (CAD) and computer-aided manufacturing (CAM) software tools that can generate a three-dimensional model of the desired product.

The importance of rapid prototyping lies in its ability to help companies create and refine product designs quickly and cost-effectively. Manufacturers can use rapid prototyping to test their designs and identify any issues before they invest time and resources in large-scale production.

-

2.Working Principles of Rapid Prototyping

Rapid prototyping is an innovative manufacturing process that involves a combination of different techniques to create 3D physical prototypes from digital designs. The working principles of rapid prototyping include:

- Additive Manufacturing Process: Additive manufacturing is the primary process used in rapid prototyping. The process involves building parts or products layer-by-layer using a 3D printer. Additive manufacturing starts with the creation of a digital file of the object to be produced, which is then sent to a 3D printer for fabrication. The printer reads the digital design file and creates each layer by depositing or curing material. The process continues until a final 3D object is produced.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD and CAM software are the tools used in rapid prototyping to create digital designs that can be efficiently translated into physical prototypes. CAD software is used to create a virtual 3D model of the object to be produced, while CAM software is used to convert the design into machine instructions that are used by the 3D printer for fabrication.

- Material Selection: Material selection is an essential part of the rapid prototyping process. Different materials, such as thermoplastics, thermosets, metals, and composites, can be used in 3D printing, depending on the requirements of the application. Material selection involves considering mechanical properties, safety, longevity, and other criteria specific to the intended application.

In conclusion, the working principles of rapid prototyping involve using additive manufacturing processes, computer-aided design (CAD) and computer-aided manufacturing (CAM) software tools, and careful material selection to create rapid and cost-effective physical prototypes of digital designs.

-

3.Types of Rapid Prototyping Techniques

There are several types of rapid prototyping techniques, each of which uses a slightly different approach to create physical parts or prototypes from digital designs. Here are some of the most common types of rapid prototyping techniques:

- Stereolithography (SLA): Stereolithography uses a laser to cure photosensitive resin into a three-dimensional shape. The process involves a vat of liquid resin and a platform that can move up and down. The laser traces the digital design on the surface of the liquid resin, curing it into a solid layer.

- Fused Deposition Modeling (FDM): FDM is the most commonly used 3D printing technology, and it works similarly to extrusion. It involves heating and extruding a thermoplastic filament onto the build platform layer by layer.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered material, such as nylon, into a three-dimensional object. The process involves spreading a thin layer of powder over the build platform, and the laser then melts the powder particles together to form a solid layer.

- Digital Light Processing (DLP): DLP uses a projector to cure photosensitive resin into a three-dimensional shape. The projector flashes a single image of each layer onto the build platform, and the resin is cured with a UV light.

- PolyJet Printing: PolyJet printing uses an inkjet-like process to deposit photopolymers onto the build platform. The material is cured with UV light after being deposited.

- Laminated Object Manufacturing (LOM): LOM uses layers of adhesive-coated paper or plastic that are cut out to match the desired shape using a laser or blade. The cut layers are then glued together to build the final three-dimensional object.

Each of these rapid prototyping techniques offers unique advantages in terms of speed, accuracy, material options, and cost-effectiveness, making them suited to different applications and industries.

-

4.Advantages of Rapid Prototyping

Rapid prototyping offers a range of benefits for manufacturers, helping to streamline the product development process and accelerate time-to-market. Here are some of the most significant advantages of using rapid prototyping:

- Cost-effective and Time-efficient Prototyping: Traditional prototyping techniques, such as casting and molding, can be time-consuming and expensive, particularly when creating complex geometries. Rapid prototyping, on the other hand, is a quick and cost-effective way of producing physical prototypes from digital designs, saving manufacturers considerable time and money.

- Design Flexibility: Rapid prototyping allows for design freedom, enabling designers to get creative and prototype their products in any shape, size, or complexity. Digital designs can be customized quickly, and the prototypes can be adapted, and designs reworked faster than traditional prototyping methods.

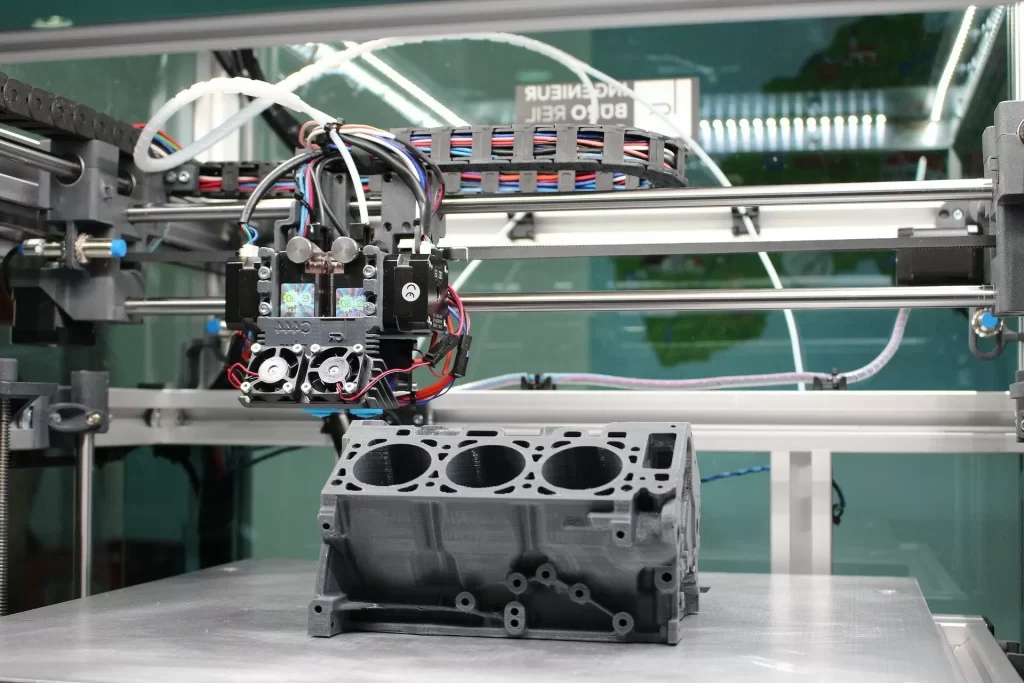

- Prototyping Complex Objects: Rapid prototyping enables the quick creation of complex parts and objects that would otherwise be impossible to produce using traditional methods. The process can produce parts with intricate details and geometries, making it a valuable tool for testing and validation.

- Reduction in Material Waste: Rapid prototyping uses only the amount of material needed for each model, unlike traditional methods that can leave behind significant waste. The process of rapid prototyping is highly efficient in terms of material use, which is also better for the environment.

In conclusion, rapid prototyping is a valuable tool for manufacturers, offering significant advantages, including cost-effective and time-efficient prototyping, design flexibility, the ability to prototype complex objects, and reduction in material waste. By using rapid prototyping, manufacturers can accelerate the product development process, iterate designs quickly, and test product performance before committing to full-scale production.

-

5.Applications of Rapid Prototyping

Rapid prototyping is a versatile manufacturing process that has found numerous applications across various industries. Here are some of the most common applications of rapid prototyping:

- Product Design and Development: Rapid prototyping is commonly used in product design and development to create physical prototypes of new products. It enables designers and engineers to test and validate their designs quickly, identify any flaws or issues, and iterate the designs until the final product is ready for production.

- Medical Industry: Rapid prototyping is used in the medical industry to create patient-specific models for surgical planning and training. It is also used to create customized prosthetics and implants that fit the patient’s body perfectly.

- Aerospace and Automotive Industry: Rapid prototyping is used in the aerospace and automotive industries to create functional prototypes of components such as engine parts, exhaust systems, and interior trim components. The process enables engineers to test and validate designs before committing to costly tooling and production runs.

- Art and Sculpture: Rapid prototyping is used in the art industry to create three-dimensional models of sculptures and art pieces. Rapid prototyping enables artists to explore different designs and modify them easily, saving time and resources while creating the final art piece.

In conclusion, rapid prototyping has found numerous applications in various industries, including product design and development, medical, aerospace and automotive industry, and art and sculpture. The process provides a quick and cost-effective way of creating prototypes, enabling manufacturers to test designs quickly, identify issues, and make modifications before committing to full-scale production.

-

6.Limitations of Rapid Prototyping

Despite the many benefits of rapid prototyping, there are some limitations to the process that must be considered. Here are some of the most common limitations of rapid prototyping:

- Material Limitations: The range of materials that can be used in rapid prototyping is limited compared to traditional manufacturing techniques. While new materials are continually being developed, the current range is more limited, and the mechanical properties of many of the available materials may not be suitable for some applications.

- Functionality Constraints: Rapid prototyping is not always suitable for producing parts that are highly functional or that require specific specifications. The process may not be able to deliver the required accuracy or durability for some critical components, making it necessary to explore alternative manufacturing techniques.

- Technology Limitations: Each rapid prototyping technique has its own limitations in terms of the size, shape, and complexity of the parts that can be produced. Additionally, the cost of rapid prototyping can be prohibitive for some applications, making it necessary to carefully assess the cost-benefit trade-offs of using the process.

In conclusion, while the benefits of rapid prototyping are significant, there are some limitations to the process that must be considered. These include materials limitations, functionality constraints, and technology limitations, all of which can impact the suitability of the process for a specific application. By carefully assessing these potential constraints, manufacturers can make informed decisions about whether or not to use rapid prototyping and which technique to use for a specific application.

-

7.Future Outlook of Rapid Prototyping

Rapid prototyping has evolved considerably over the years, and new innovations and technologies are continuing to be developed that will enable even greater possibilities in the future. Here are some of the trends that are likely to shape the future of rapid prototyping:

- Integration with Artificial Intelligence and Machine Learning: The integration of artificial intelligence and machine learning into the rapid prototyping process will enable manufacturers to optimize the process and achieve even greater efficiency and accuracy. Machine learning algorithms can be used to optimize the design of parts for specific product requirements, while AI can be used to monitor and optimize the 3D printing process in real-time.

- Advancements in Material Science: Advancements in material science will provide a broader range of materials options in rapid prototyping, enabling manufacturers to create parts with specific properties, such as strength, durability, or flexibility. New materials technology such as metal 3D printing will enable the production of complex metal parts.

- Increased Adoption in Industries: Rapid prototyping is becoming increasingly common in various industries such as healthcare, aerospace, automotive, manufacturing and consumer products. With the continued development of the process, more and more industries are likely to adopt the technology to boost their product development cycles and improve the quality of their products.

In conclusion, the future of rapid prototyping is bright, with innovations such as AI and machine learning, material science advancements, and increased adoption across various industries. As a result, manufacturers will be able to create product designs and innovative solutions more effectively and efficiently, resulting in better products and faster time-to-market.

If you need more about Rapid Prototyping information ,You can click on the V1 Prototype website to find it.

-

8.Conclusion

In conclusion, rapid prototyping plays a vital role in product development and offers several benefits. It is a cost-effective and time-efficient process that enables manufacturers to produce physical prototypes from digital designs quickly. It offers design flexibility and the ability to prototype complex objects that are challenging to create with traditional manufacturing methods. Rapid prototyping has applications in product design and development, medical, aerospace and automotive industries, art, and sculpture, among others.

However, rapid prototyping has limitations such as material limitations, functionality constraints, and technology limitations that must be considered when deciding whether to use the process. The future of rapid prototyping looks promising, with innovations such as AI and machine learning, advancements in material science, and increased adoption across various industries.

Overall, rapid prototyping is an essential tool for manufacturers that are committed to innovation and rapid product development. By using this technology in the early stages of design and development, manufacturers can create better products quickly, more efficiently, and with fewer costs while achieving improved quality features.