Automotive Fixture Services

9 years of experiences focusing on manufacturing of Automotive checking fixture, cooling jigs of plastic parts. ISO9001 ISO14001 and IATF16949 Quality Management System to guarantee high-quality fixture.

Automotive Fixture Services

Our company is focusing on design and manufacturing of Automotive checking fixture, various kinds of gauges, cooling jigs of plastic parts for 9 years, we have 40 experienced technical staff and introduced more than 20 sets of advanced facilities from Japan and Taiwan to meet different customer’s needs to ensure the high-quality and on-time delivery checking fixture.

Meanwhile, we have offices and overseas team in European and US countries to provide our powerful local support.

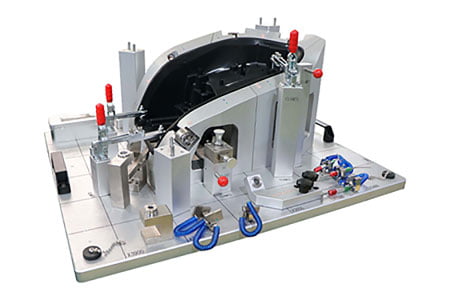

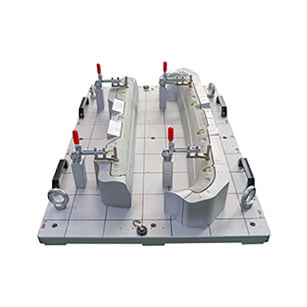

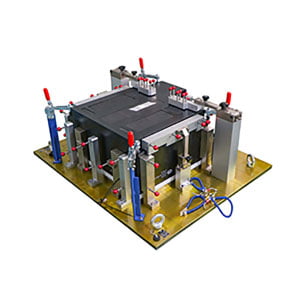

Automotive Fixture Products

Automotive Fixture Capacity For Customers

- 9 years of rich experiences in checking fixture manufacturer in China.

- Customized fixture design and manufacturing with strong production capacity.

- ISO9001 ISO14001 and IATF16949 Quality Management System to guarantee high-quality fixture.

- Powerful overseas local support service from pre-sales communication, technical support and after-sales service.

Our Automotive Fixture partners

With our rich experience of toolmaking, powerful local support from our overseas team and reasonable price, we have established long term win-win business cooperation with worldwide well-know companies.

Automotive Fixture Manufacturing FAQs

An automotive fixture is a device used to support and position automotive components to improve productivity and quality during automotive manufacturing and repair.

There are many types of automotive fixtures, including assembly fixtures, inspection fixtures, painting fixtures, welding fixtures, etc., and each type of fixture has a different purpose and design.

The manufacturing process of automobile fixtures includes steps such as design, processing, assembly and debugging. Designers design fixtures according to customer requirements, and then the machining department uses machines and tools to manufacture parts and assemble them. Finally, technicians debug to ensure the normal operation of the fixture.

Automotive fixtures can increase productivity, reduce human error and the risk of damaged components. They also improve product consistency and quality, and reduce manufacturing and repair costs.

Yes, automotive fixtures require regular maintenance and inspections to keep them functioning properly. This prevents mechanical failure and damage and extends the life of the fixture.

The material of automotive fixtures is usually steel or aluminum, depending on the application scenario and usage requirements.

The maximum load capacity of automotive clamps varies by type and design. Generally speaking, car clamps can carry a weight of several hundred to several thousand kilograms.

Standards for automotive fixtures are usually set by international or national standards bodies, such as ISO, ANSI, etc. These standards include the size of the fixture, load capacity, safety requirements, etc.

The safety of automotive fixtures can be guaranteed through safety considerations in the design and manufacturing process, regular maintenance and inspection, and correct operation and safety precautions during use.

The installation and removal of automotive clamps need to follow specific steps and procedures to ensure that they are correct and safe. Installation and removal need to consider the weight of the fixture

Common question in Automotive Fixture Production

Yes, automotive fixtures can be customized according to customer requirements to suit different application needs and usage scenarios.

The accuracy of automotive fixtures can be guaranteed through strict control and precision measurements during processing and assembly. In addition, regular maintenance and inspection can also ensure the accuracy of the fixture.

Yes, automotive jigs can be reused, but they require regular maintenance and inspection to ensure proper functioning and accuracy.

The service life of an automotive fixture depends on factors such as its material, design, frequency of use, and maintenance. In general, fixtures with normal use and maintenance can last anywhere from a few years to decades.

Errors in automotive fixtures can be avoided through precise design and manufacturing processes, regular maintenance and inspections, and correct operations and precautions during use.

The price of an automotive fixture depends on factors such as its material, manufacturing difficulty, precision requirements, and degree of customization. In general, custom fixtures are more expensive than standard fixtures.

The safety inspections required for automotive fixtures include inspections of the load-bearing capacity of the fixture, damage or wear of the fixture material, the way the fixture is fixed, and the integrity of the safety device.

Yes, automotive fixtures can be installed and debugged on site to ensure that they are adapted to specific application scenarios and requirements.

Automobile fixtures can be applied to various auto parts, such as body, chassis, engine, transmission system, electrical system, etc.

The application range of automobile fixtures includes automobile manufacturing, maintenance, modification and research and development, and can be applied to various types of automobiles and parts.