Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. This process is used to create a variety of plastic products, from toys to medical devices to automotive parts. In this article, we'll provide a comprehensive guide to plastic injection molding services, covering everything you need to know about the process, the equipment, and the benefits of working with a professional molding company.

Catalogue:

- Introduction

- What is plastic injection molding?

- The plastic injection molding process

- Equipment used in plastic injection molding

- Advantages of plastic injection molding services

- Choosing the right plastic injection molding company

- Conclusion

Plastic injection molding Introduction:

Plastic injection molding is a manufacturing process that has been in use for over a century. It involves the creation of plastic products through the injection of molten plastic into a mold cavity. This process has revolutionized the production of plastic products and has enabled manufacturers to create high-quality, precision products at a low cost.

If you are considering using plastic injection molding services for your manufacturing needs, it's essential to understand the process, the equipment used, and the benefits of working with a professional molding company. This article will provide a comprehensive guide to plastic injection molding services, covering everything you need to know about the process, the equipment, and the advantages of working with a professional molding company.

What is plastic injection molding?

Plastic injection molding is a manufacturing process that involves the injection of molten plastic into a mold cavity. The molten plastic is injected into the mold under high pressure, and once it has cooled and solidified, it is ejected from the mold. The mold is then ready for the next cycle of the injection molding process.

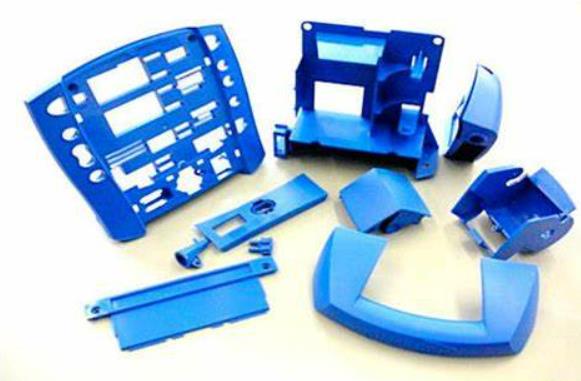

The plastic injection molding process is used to create a variety of plastic products, including medical devices, toys, automotive parts, and household appliances. The process can produce products in a range of sizes, from small, intricate parts to large, complex structures.

The plastic injection molding process:

The plastic injection molding process involves several steps, including material selection, mold design, injection molding, and product finishing. Here is an overview of the steps involved in the plastic injection molding process:

- Material selection: The first step in the plastic injection molding process is material selection. The type of plastic used in the process will depend on the specific product being produced, as well as the properties required of the final product.

- Mold design: Once the material has been selected, the next step is mold design. The mold is designed to create the shape of the final product, and it must be carefully designed to ensure the final product meets the required specifications.

- Injection molding: Once the mold has been designed, the injection molding process can begin. The mold is clamped shut, and the molten plastic is injected into the mold cavity under high pressure. The plastic is then left to cool and solidify.

- Product finishing: Once the plastic has solidified, the product is ejected from the mold, and any excess plastic is trimmed away. The product may then be subjected to additional finishing processes, such as painting, polishing, or assembly.

Equipment used in plastic injection molding:

The plastic injection molding process requires specialized equipment to heat and inject the plastic into the mold cavity. Here are the key pieces of equipment used in plastic injection molding:

- Injection molding machine: The injection molding machine is the heart of the plastic injection molding process. It is responsible for heating the plastic to the correct temperature and injecting it into the mold cavity under high pressure.

- Mold: The mold is the tool used to create the shape of the final product. The mold is designed to withstand high pressure and temperature, and it must be carefully designed to ensure the final product meets the required specifications.

- Auxiliary equipment: In addition to the injection molding machine and mold, there are several other pieces of equipment that are used in the plastic injection molding process. These include temperature controllers, material dryers, and material handling equipment.

Advantages of plastic injection molding services:

Plastic injection molding offers a wide range of benefits for manufacturers, including precision and consistency, speed and efficiency, and reduced waste and cost-effectiveness. Here are some of the key advantages of plastic injection molding services:

- Precision and consistency: Plastic injection molding is a highly precise process that allows manufacturers to create products with tight tolerances and intricate details. The process is highly repeatable, ensuring that each product is consistent in quality and appearance.

- Speed and efficiency: Plastic injection molding is a fast and efficient process that allows manufacturers to produce large quantities of products quickly and efficiently. The process can be automated, further increasing efficiency and reducing labor costs.

- Reduced waste and cost-effectiveness: Plastic injection molding is a highly efficient process that produces little waste. The process can use recycled materials, further reducing costs and environmental impact. Additionally, plastic injection molding is often more cost-effective than other manufacturing processes, such as CNC machining or 3D printing.

Choosing the right plastic injection molding company:

If you are considering using plastic injection molding services for your manufacturing needs, it's important to choose the right molding company. Here are some factors to consider when selecting a plastic injection molding company:

- Experience: Look for a molding company with experience in your industry and with the specific products you need to produce.

- Quality: Choose a molding company with a proven track record of producing high-quality products.

- Capacity: Ensure that the molding company has the capacity to produce the quantity of products you require.

- Equipment: Choose a molding company with modern, well-maintained equipment.

- Customer service: Look for a molding company that is responsive to your needs and provides excellent customer service.

Plastic injection molding Conclusion:

Plastic injection molding is a highly efficient and cost-effective manufacturing process that is used to produce a wide range of plastic products. The process requires specialized equipment and expertise, and it's important to choose the right plastic injection molding company to ensure high-quality, consistent products. By understanding the plastic injection molding process and the benefits of working with a professional molding company, you can make informed decisions about your manufacturing needs and achieve the best possible outcomes.