Development Of Hot Runners

- History

Hot runner system originated in the injection moulding industry without runner system, as an advanced plastic injection moulding processing technology, the popular use in the western developed countries can be traced back to the middle of the last century or even earlier.

Hot runner has many advantages, therefore, the development is relatively fast in foreign countries, many plastic mould factories produce more than 50% of the moulds using hot runner technology, some mould factories even reached more than 80%. In China, this technology in the last ten years before the real full promotion and application, with the continuous development of the mould industry, hot runner in plastic moulds using the proportion also gradually increased, but on the whole has not reached the proportion of foreign hot runner moulds.

- Now

The gradual spread of hot runner technology in China in recent years has been brought about in large part by the rapid growth in the volume of mould exports from China to European and American companies. In Europe and the USA, injection moulding production already relies on hot runner technology.

- Future

Without the use of hot runner technology moulds are now difficult to export, which has also caused many mould manufacturers for hot runner technology awareness of the change.

The principle of hot runners

- Cold runners versus hot runners

A cold runner is the part between the mould inlet and the product gate. The plastic is kept flowing by the injection pressure and its own heat in the runner, which is part of the moulded material, but not part of the product. So when we design the mould we have to consider both the filling effect and how to save material by shortening and narrowing the runner, ideally, but in practice it is difficult to achieve the best of both worlds.

Hot runners, also known as runnerless runners, mean that the plastic in the runner does not solidify after each injection, so that the water outlet in the runner does not have to be removed when the plastic product is demoulded. As the plastic in the runner does not solidify, the runner remains open for the next injection. In short, the hot runner is an extension of the injection moulding machine nozzle.

- Characteristics of hot runner moulds

Why is this hot runner technology available? What benefits can hot runner technology bring to us? Engineers familiar with the injection moulding process will know that conventional injection moulding is often associated with the following disadvantages

a. Difficulties in filling.

b. The tendency to deform thin-walled large parts.

c. Waste of raw material in the sprue.

d. Inconsistent quality of injection moulded parts from multi-cavity moulds.

The advent of hot runner technology has provided a more complete solution to these problems and, in general, the use of hot runners has the following advantages.

Advantages of a hot runner system

(1)Shortening the cycle time of the part

As there is no cooling time limit for the sprue system, the part can be ejected in time once it has been formed and cured. Many thin-walled small parts produced with hot runner moulds can be moulded in less than 5 seconds.

(2)Savings in plastic material

In full hot runner moulds there are no cold gates, so there are no production costs. This is particularly significant for applications where plastics are expensive. In fact, the major international hot runner manufacturers have grown rapidly in an era when the world's oil and plastic raw materials were expensive, because hot runner technology is an effective way to reduce scrap and lower raw material costs.

(3) Reduce scrap and improve product quality

During the hot runner moulding process, the temperature of the plastic melt is accurately controlled in the runner system. The plastic can flow more uniformly into each cavity, resulting in consistent quality parts. Hot runner moulded parts have good gate quality, low residual stresses after demoulding and low part distortion. This is why many of the highest quality products on the market are produced by hot runner moulds.

(4)Elimination of subsequent processes, conducive to production automation

After the hot runner mould is formed, the part is finished, so there is no need to trim the gate and recycle the cold sprue, which is conducive to production automation. Many manufacturers at home and abroad have combined hot runner and automation to significantly improve production efficiency.

(5) Expand the scope of application of injection moulding process

Many advanced plastic molding process is based on the development of hot runner technology. Such as PET preform manufacturing, in the mold of multi-color co-injection, a variety of materials co-injection process, STACK MOLD (stack box casting mold), etc……

Although hot runner moulds have many significant advantages over cold runner moulds, mould users also need to be aware of the disadvantages of hot runner moulds. In summary, these are as follows.

Disadvantages of a hot runner system

(1)Rising mould costs

Hot runner components are more expensive and the cost of hot runner moulds can increase significantly. If part production is small, the high proportion of mould tooling costs is not economically viable. For many mould users in developing countries, the expensive price of hot runner systems is one of the main issues affecting the widespread use of hot runner moulds.

(2) hot runner mould production process equipment requirements are high

Hot runner moulds need precision processing machinery as a guarantee. Hot runner system and mold integration and cooperation requirements are extremely strict, otherwise the mold in the production process will appear many serious problems.

(3)Complex operation and maintenance

Compared with cold runner moulds, hot runner moulds are complicated to operate and maintain. If the use of improper operation is very easy to damage the hot runner parts, so that production can not be carried out, resulting in huge economic losses. For new users of hot runner moulds, it takes a long time to accumulate experience in using them.

Components of a hot runner system

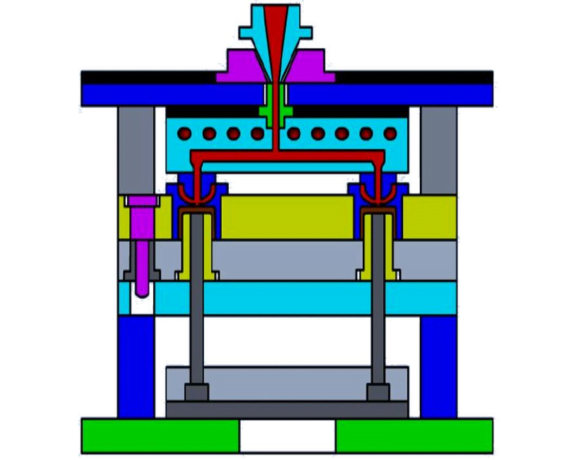

Although there are many hot runner manufacturers and a wide range of hot runner products in the world, a typical hot runner system consists of the following components: hot runner plate, nozzle, temperature controller and auxiliary parts.

A successful hot runner mould application project requires a number of components. Two of the most important technical factors are the control of the plastic temperature and the control of the flow characteristics of the plastic.

(1)Control of plastic temperature

In hot runner mould applications the control of plastic temperature is extremely important. Many of the processing and product quality problems that occur in the production process come directly from the poor temperature control of the hot runner system. Examples include poor gate quality when moulding with torpedo-style hot nozzles, difficulties in fully closing the valve pin when moulding with valve-style hot nozzles and inconsistent part filling times and quality in multi-cavity moulds. If possible, try to choose a hot runner system with multi-zone section temperature control to increase flexibility and resilience.

(2)Control of plastic flow

The flow of plastic in a hot runner system should be balanced. Gates should be opened simultaneously to allow the plastic to fill the cavities simultaneously. For parts with a large difference in weight, the sprue size should be designed to balance. Otherwise there will be problems such as insufficient mould filling and pressure retention for some parts, but excessive mould filling and pressure retention for others and poor quality flying edges. The hot runner sprue size should be reasonable. If the size is too small, the mould pressure loss is too large. If the size is too large, the volume of the hot runner is too large and the plastic stays in the hot runner system for too long, destroying the material properties and causing the parts to fail to meet the requirements of use after moulding.