Table of Contents:

- Introduction to Blow Molding Services

- Techniques of Blow Molding

- Applications of Blow Molding Services

- Advantages of Blow Molding Services

- Blow Molding Services Process Overview

- Choosing the Right Blow Molding Service Provider

- Conclusion

-

1.Introduction to Blow Molding Services

Blow molding is a manufacturing process used to create hollow plastic objects. It involves melting plastic and then shaping it into a hollow form by blowing air into it. This process is commonly used in the production of plastic bottles, containers, and other similar items.

The history of blow molding dates back to the 1800s when glass blowers began using the technique to create glass bottles. However, the use of plastic for blow molding only became popular in the mid-20th century.

There are several types of blow molding services, including extrusion blow molding, injection blow molding, stretch blow molding, co-extrusion blow molding, and rotational blow molding. Each type of blow molding service has its own unique advantages and applications.

-

2.Techniques of Blow Molding

Blow molding is a versatile manufacturing process that uses different techniques to create a variety of plastic products. Here are some of the most common techniques of blow molding:

- Extrusion blow molding: This technique involves melting plastic resin and then extruding it into a hollow tube. The tube is then clamped into a mold, and compressed air is blown into the tube to form the desired shape.

- Injection blow molding: This process begins with the creation of a preform, which is a small plastic tube with a threaded neck. The preform is then inserted into a mold cavity, where it is inflated with compressed air to form the final product.

- Stretch blow molding: In this technique, a preform is heated and stretched in two directions to increase its length and diameter. It is then inflated with compressed air to create the final product.

- Co-extrusion blow molding: This process involves the use of multiple layers of plastic resin to create a product with different properties, such as increased strength or barrier protection.

- Rotational blow molding: This technique involves heating a plastic resin inside a rotating mold. The mold is rotated while compressed air is blown into it, creating a hollow product with a uniform wall thickness.

Each of these techniques has unique advantages and is suited for different applications. The choice of technique depends on factors such as the desired product characteristics, production volume, and cost.

-

3.Applications of Blow Molding Services

Blow molding services are widely used in various industries due to their ability to produce high-quality, durable, and cost-effective products. Here are some of the common applications of blow molding services:

- Packaging industry: Blow molding is extensively used in the packaging industry to produce plastic containers, bottles, jars, and other packaging products. These products are lightweight, cost-effective, and have excellent barrier properties, making them ideal for storing food, beverages, chemicals, and pharmaceuticals.

- Automotive industry: Blow molding is used in the automotive industry to manufacture various parts such as air ducts, fuel tanks, and engine covers. The process offers excellent design flexibility, allowing the production of parts with complex shapes and intricate details.

- Consumer goods industry: Blow molding is used to produce a wide range of consumer goods such as toys, sporting equipment, and household items. These products are lightweight, durable, and affordable, making them popular among consumers.

- Medical industry: Blow molding is used in the medical industry to produce a variety of products such as medical devices, diagnostic equipment, and packaging for medical products. The process offers excellent precision, allowing the production of parts with precise dimensions and tight tolerances.

- Aerospace industry: Blow molding is used in the aerospace industry to produce lightweight and durable parts such as fuel tanks, ducts, and airframes. The process offers excellent strength-to-weight ratio, making it ideal for producing parts that can withstand extreme conditions.

Overall, blow molding services offer a wide range of applications across various industries due to their versatility, efficiency, and cost-effectiveness.

Click on the V1 Prototype website to gain more Blow Molding Services information.

-

4.Advantages of Blow Molding Services

Blow molding services offer several advantages over other manufacturing processes. Here are some of the most significant advantages of blow molding services:

- Cost-effective production: Blow molding is an efficient and cost-effective manufacturing process that can produce large volumes of high-quality products at a low cost. The process can use a wide range of materials, including recycled materials, further reducing the production cost.

- Design flexibility: Blow molding offers excellent design flexibility, allowing manufacturers to produce parts with complex shapes, intricate details, and various sizes. The process can produce products with thin walls and intricate shapes that are not possible with other manufacturing processes.

- Lightweight and durable products: Blow molding produces products that are lightweight and durable, making them ideal for various applications, including packaging, automotive, and aerospace industries. These products offer excellent strength-to-weight ratio and can withstand harsh environments and extreme temperatures.

- Environmentally friendly manufacturing process: Blow molding is an environmentally friendly manufacturing process that uses less energy and resources compared to other manufacturing processes. The process produces less waste and can use recycled materials, making it an eco-friendly option.

- Wide range of materials: Blow molding can use a wide range of materials, including HDPE, LDPE, PP, PET, PVC, and others, providing a broad range of options for manufacturers to choose from depending on their product requirements.

Overall, blow molding services offer a cost-effective, efficient, and versatile manufacturing process that produces high-quality products with excellent design flexibility and environmental benefits.

-

5.Blow Molding Services Process Overview

Blow molding services involve a series of processes to produce high-quality plastic products. Here is an overview of the typical blow molding process:

- Preparation and melting of raw materials: The process begins with the preparation and melting of the raw materials, which are typically plastic resins. The plastic resin is melted and then shaped into a parison, which is a hollow tube that is clamped into a mold.

- Molding process: Once the parison is in the mold, compressed air is blown into the parison to expand it and take the shape of the mold cavity. The mold is then cooled to solidify the plastic, forming the desired shape of the product.

- Cooling and trimming of the product: After the product is formed, it is removed from the mold, and any excess material is trimmed off. The product is then cooled to its final shape and size.

- Quality control and inspection: Finally, the product undergoes quality control and inspection to ensure that it meets the desired specifications. The product is tested for dimensional accuracy, wall thickness, and other quality criteria to ensure that it meets the required standards.

Overall, the blow molding process is a highly efficient and reliable method for producing high-quality plastic products. It is a cost-effective process that is suitable for producing products in large volumes with excellent design flexibility and precision.

-

6.Choosing the Right Blow Molding Service Provider

Choosing the right blow molding service provider is critical to the success of your project. Here are some factors to consider when selecting a blow molding service provider:

- Experience: Look for a blow molding service provider with extensive experience in the industry. A company with a proven track record and a history of successful projects is more likely to deliver high-quality products and services.

- Quality: Quality should be a top priority when selecting a blow molding service provider. Look for a company that has robust quality control systems in place and can provide certification for their products.

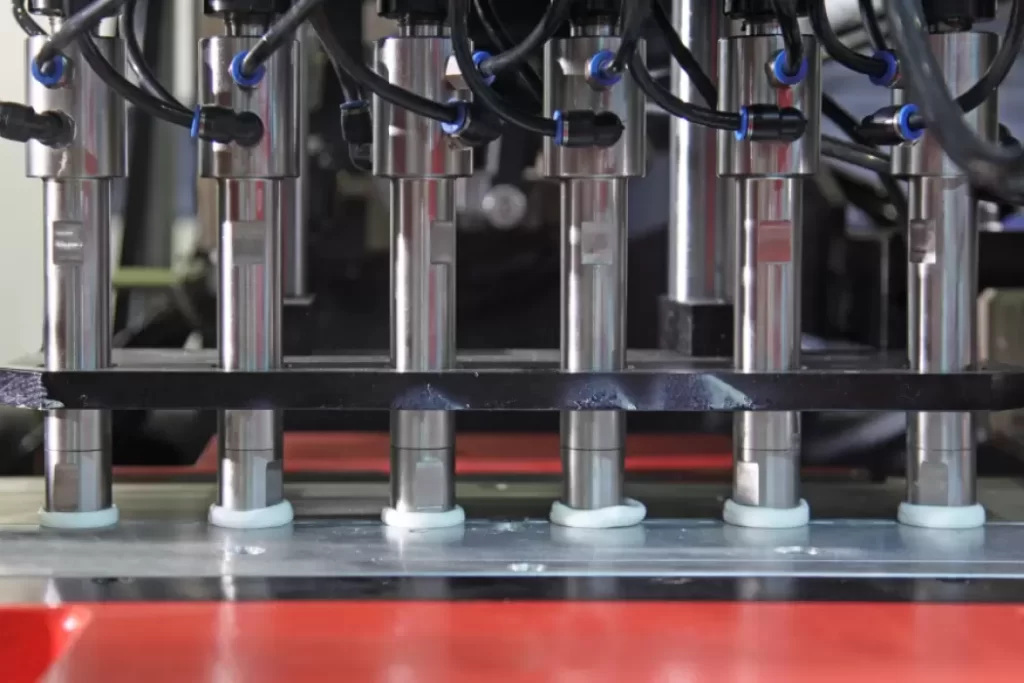

- Technology and equipment: A blow molding service provider with modern equipment and technology is more likely to produce high-quality products efficiently. Look for a company that invests in the latest technology and equipment to stay ahead of the competition.

- Capacity: Consider the capacity of the blow molding service provider to ensure that they can handle your project’s requirements. Look for a company with the necessary resources and infrastructure to meet your production needs.

- Customer service: Look for a blow molding service provider that values customer service and can provide responsive communication and support throughout the project.

Here are some questions to ask a blow molding service provider:

- What is your experience in blow molding, and can you provide examples of similar projects you have completed?

- What quality control systems do you have in place, and can you provide certification for your products?

- What technology and equipment do you use, and how do they ensure high-quality products?

- What is your production capacity, and how do you manage lead times and deadlines?

- How do you communicate with clients throughout the project, and what support do you provide after the project is complete?

-

7.Conclusion

Blow molding services offer a cost-effective and efficient method for producing high-quality plastic products across a wide range of industries. Key takeaways from this article include:

- Blow molding is a process that involves the melting and shaping of plastic resins into a desired product using compressed air and molds.

- There are various techniques of blow molding, including extrusion, injection, stretch, co-extrusion, and rotational blow molding, each suited for specific applications.

- Blow molding services are used in a variety of industries, including packaging, automotive, consumer goods, medical, and aerospace.

- The advantages of blow molding services include cost-effectiveness, design flexibility, lightweight and durable products, environmentally friendly manufacturing, and a wide range of materials.

- When selecting a blow molding service provider, factors to consider include experience, quality, technology and equipment, capacity, and customer service.

- A successful collaboration with a blow molding service provider requires clear communication, responsive support, and the provider’s ability to meet the project’s requirements.

Looking to the future, advancements in technology and materials are expected to drive continued growth in the blow molding industry. As demand for sustainable and environmentally friendly products increases, blow molding services will likely continue to play a critical role in the manufacturing of plastic products.