Table of Contents

- Introduction

- Traditional Injection Moulding

- Advanced Injection Moulding Techniques

- Comparison of Different Types of Injection Moulding Techniques

- Practical Tips for Successful Injection Moulding

- Conclusion

-

1.Introduction

Injection moulding is a manufacturing process in which molten plastic is injected into a mould cavity to create a specific shape. The process is ideal for creating high-volume, low-cost, and complex plastic parts with excellent durability features. Injection moulding is a versatile technology, making several applications possible across different industries.

The history of injection moulding dates back to the 1860s when the first injection moulding machine was invented. Over the years, the process has continued to evolve and improve, allowing manufacturers to create products with a high degree of accuracy and consistency while minimizing production costs. Today, the use of advanced techniques and technologies has made injection moulding a vital part of modern manufacturing processes.

-

2.Traditional Injection Moulding

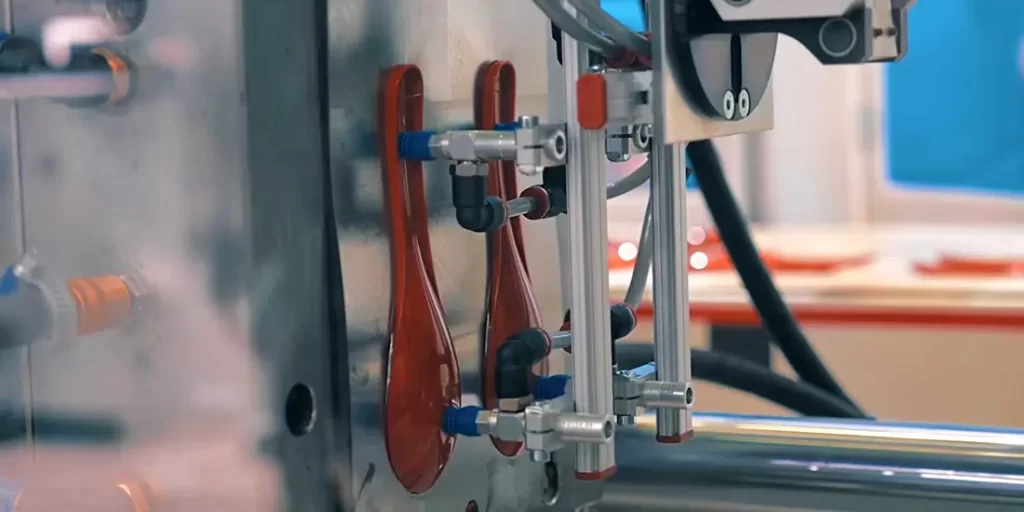

Explaining Traditional Injection Moulding Process

Traditional injection moulding is a process that involves the melting of granular or powdered plastic resin and injecting it into a mould cavity under high pressure. The injection is done using an injection unit containing a screw that preheats, melts and injects the plastic granules or powder.

When the molten plastic is injected, it fills the mould cavities and then is cooled to the desired temperature required to set the material. Once cooled, the mould is opened, and the finished part is ejected.

Characteristics of Traditional Injection Moulding

Traditional injection moulding has several key characteristics, including:

- High-volume production capability

- Achieves high repeatability and accuracy of parts manufacture

- Enables design flexibility and part complexity

- Facilitates multiple moulding operations in one cycle

- Reasonable initial setup cost

- Little post-processing is required

.

Advantages and Disadvantages of Traditional Injection Moulding

Advantages:

- Can produce complex parts with high accuracy and repeatability.

- High production rates with consistent quality.

- Wide range of plastic material choices.

- Minimal material wastage.

.

Disadvantages:

- Significant initial machine and mold setup costs

- High-volume production costs is not suitable for small-batch orders

- Large machines may require significant space for operation

- Release of unwanted gases during melting can potentially cause health hazards.

-

3.Advanced Injection Moulding Techniques

Overmolding:Overmolding is an advanced injection moulding technique that involves the injection of two or more materials over one another to produce a single finished product. The process allows manufacturers to create parts with soft-touch or anti-slip features or to assemble two or more materials of differing properties into a single part. The process can also provide superior grip, vibration dampening, and sound reduction.

Gas-Assisted Injection Moulding:Gas-assisted injection moulding (GAIM) is a method that leverages gas pressure to penetrate thick plastic flow and achieve uniform filling in mold cavities. This process eliminates sink marks and short shots and enhances design flexibility. The technique relies on storing pressurized gas between two melted plastic layers to produce a hollow product.

Insert Moulding:Insert moulding is an advanced injection moulding technique where one material is molded onto another material substrate. This process integrates an insert part with a plastic component by applying pressure and melting point of the materials used. Electrical components, threaded connections, and a variety of other connection points are commonly found in insert moulding bound parts.

Co-Injection Moulding:Co-injection moulding is a technique that involves injecting multiple materials into the same mould simultaneously, typically in a sandwich structure form. The process can enhance product functionality and durability through bonding of multiple materials, reinforcement of specific areas, and altering the surface properties of a final product.

In conclusion, advanced injection moulding techniques are essential to manufacturing complex parts with a range of functional properties. Each technique offers unique strengths and in combination, may open up entirely new possibilities for product design and development.

If you need about Injection Moulding Services,You can click on the V1 Prototype website to find it.

-

4.Comparison of Different Types of Injection Moulding Techniques

Strengths and Weaknesses of Different Techniques

Each type of injection moulding technique has its specific advantages and disadvantages. A brief comparison of the techniques is detailed below:

- Traditional Injection Moulding Technique: Traditional injection moulding offers high accuracy, fast production rates, a wide range of material options, and minimal material wastage. However, it comes with high initial setup cost, is not suitable for small-batch orders, and may require significant space for large machines.

- Overmolding technique: Overmolding is flexible and accommodates material combinations crucial for certain products, and produces parts with advanced properties such as added durability and comfort. But, this is a more complex process that requires careful consideration of both materials used and how placement, sequence, and timing affect the end product.

- Gas-Assisted Injection Moulding technique: GAIM provides freedom of design and lighter products, and eliminates the appearance of sink marks or short-shot marks. It can reduce injection pressure, thereby reducing machine wear, with reduced cost and cycle times. However, parts could later be difficult to recycle, and the process may require additional costs for equipment modifications or upgrades.

- Insert Moulding technique: Insert moulding provides stable and secure attachment of varied components essential for certain products. It offers reliable electrical conductivity and better wear resistance. However, it presents possible concerns with material compatibility issues and the right time for inserting any needed components.

- Co-Injection Moulding technique: Co-injection moulding helps strengthen bonding strength between two different materials, provides a uniform surface finish, and reduces warpage. But it may be an expensive process, with demand for extensive and complex testing and implementation.

Choosing the Right Technique for Your Manufacturing Needs

Choosing the right injection moulding technique to use will depend on various factors, including the intended product design, material properties, manufacturing cost, batch quantity and size limits, and more. Early collaboration with an expert in manufacturing and design could save time and costs as the design phase progresses. Evaluation of the advantages and disadvantages of each technique could also help in selecting the best option for a manufacturer’s particular application.

-

5.Practical Tips for Successful Injection Moulding

Regular Maintenance of Equipment and Tools:Regular maintenance of the injection moulding equipment and tools is essential to ensure high-quality manufacturing. This can involve:

- Avoiding long downtimes between production runs.

- Cleaning and lubricating the machines regularly.

- Calibrating the machines regularly to maintain the set points for temperature and pressure.

.

Proper Material Selection:The selection of the right materials for manufacturing is fundamental to injection moulding’s successful application. The factors that influence proper material selection include:

- The mechanical and thermal resistance of materials.

- Material durability and consistency.

- Compatibility of materials with the application environment (e.g., in contact with chemicals or exposed to ultraviolet light).

- The anticipated lifespan of the final product.

.

Process Optimization and Monitoring:The process optimization and monitoring is a critical aspect of injection moulding. This helps maintain the stability of the process variables, including temperature, pressure, cooling time, and injection speed. Some essential process optimization tasks include:

- Running test shots to evaluate the part and mould design suitability.

- Establishing process parameters.

- Conducting regular inspections throughout the production cycle, and adjusting the process variables accordingly.

.

Documentation:Documenting the manufacturing process is an essential aspect of injection moulding. Proper documentation of relevant data from each production run, especially material data, settings, and changes, can provide a useful guide for troubleshooting during future production runs. Proper documentation helps ensure continuous manufacturing improvement over time and regulatory compliance.

In conclusion, optimizing the injection moulding process requires a pragmatic approach by manufacturers to minimize costs, improve product quality, and maintain compliant operations. Thus, regular maintenance, material selection, process optimization, and monitoring, and documentation are critical to achieving a seamless and efficient injection moulding process.

-

6.Conclusion

Recap of Key Points:

- Injection moulding is a versatile and efficient manufacturing process that enables the production of various products across different sectors.

- Traditional injection moulding is a process of melting plastic resin and injecting it into a mould cavity under high pressure, enabling accurate and consistent production of high-volume, low-cost, and complex plastic parts.

- Advanced injection moulding techniques such as overmolding, gas-assisted injection moulding, insert moulding, and co-injection moulding offer added flexibility and product performance.

- Choosing the right injection moulding technique for a specific application will depend on various factors, including product design, material properties, and manufacturing cost.

- Proper maintenance of equipment and tools, material selection, process optimization and monitoring, and documentation are essential for a successful injection moulding process.

Final Thoughts:

Injection moulding is an essential manufacturing process that continues to revolutionize the production of different products across various industries. With the adoption of advanced injection moulding techniques, manufacturers can significantly improve the final product’s properties and functionality. To achieve successful injection moulding production, it is essential to take proactive steps in maintaining equipment and tools, selecting the right materials, optimizing and monitoring the manufacturing process rigorously while documenting every step of the process. By applying these practical tips, manufacturers can achieve high-quality, cost-effective, and efficient production, while ensuring regulatory compliance and continuous process improvement.