- Introduction

- The 2K Injection Molding Process

- Advantages of 2K Injection Molding

- Practical Applications of 2K Injection Molding

- Challenges and Considerations

- Future of 2K Injection Molding

- Conclusion

-

1. Introduction:

2K injection molding is a highly precise manufacturing process that involves the use of two different materials in a single plastic injection molding process. This unique process enables the production of highly complex and sophisticated products with sleek surface finishes. In this section, we will provide an overview of 2K injection molding and highlight its importance in the manufacturing industry.

-

2. The 2K Injection Molding Process:

The 2K injection molding process requires two different materials to be injected simultaneously into the same mold. Here are the critical aspects of the 2K injection molding process:

- Description of the Process: The process involves the use of two different plastic raw materials that are injected into a single mold. The first material forms the product’s body or frame, while the second material forms the surface or detailing of the product.

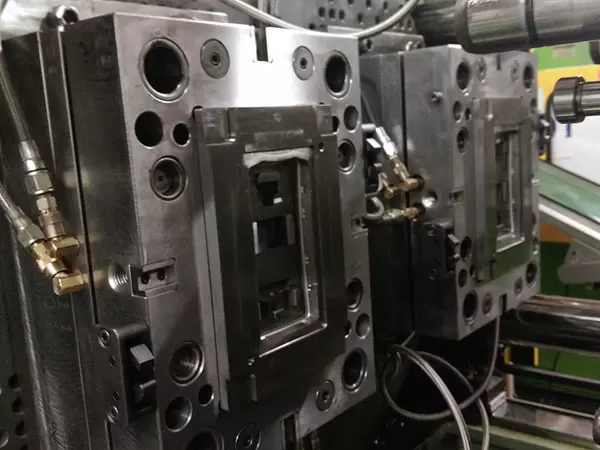

- Machine Components: The 2K injection molding machine has two injection units and two molds that are mounted on the same machine. It also has a rotating table that transfers the first molded part to the second mold after which the second material is injected.

- 2K Injection Molding Cycle: The injection process includes material preparation, injection, co-injection or transfer, packing, cooling, and ejection. The cycle time varies depending on the part’s size and complexity, with cycle times ranging from a few seconds to minutes.

The 2K injection molding process enables manufacturers to produce highly sophisticated products with sleek surface finishes.

-

3. Advantages of 2K Injection Molding:

The 2K injection molding process offers several advantages over traditional injection molding manufacturing methods. Here are the critical advantages:

- Improved Product Design: 2K injection molding enables manufacturers to produce complex designs with a high-quality surface finish that would be challenging or impossible to achieve with traditional injection molding processes. The possibility to combine different materials to create a product that improves the product’s functionality and aesthetics.

- Cost Savings: While there is an initial investment in the 2K injection molding process’s tooling equipment, the ability to produce complex, high-quality products with a single manufacturing process can reduce overall production costs, with fewer tools and processing steps required. The manufacturing process reduces scrap, leading to less waste materials, contributing towards cost savings for production.

- Enhanced Productivity: Due to the 2K injection molding process, manufacturers can produce more complex parts and products in significantly less time than traditional injection molding. The reduced cycle times increase production speed and the possibility of creating products with shorter lead time-to-market.

Understanding the advantages provided by 2K injection molding can help manufacturers improve their production outcomes with reduced cost and improved quality, functionally and aesthetically.

-

4. Practical Applications of 2K Injection Molding:

2K injection molding has a wide range of applications across several industrial sectors; here are some practical implementations:

- Automotive: 2K injection molding allows automotive components to be produced with a high-quality surface finish and sophisticated design, including interior and exterior parts such as dashboards, door panels, and handles.

- Electronics: 2K injection molding enables the production of high-quality products with sophisticated designs, surfaces and textures, such as cell phone cases, computer and electronic equipment components or casings.

- Medical Devices: Due to its ability to combine medical-grade materials with different properties, 2K injection molding is particularly useful in the medical industry for producing high-quality medical-grade devices, orthopedic components, surgical tools, and syringe barrels.

- Consumer Goods: 2K injection molding finds many applications in the consumer goods sector, where high-quality products with complex designs and surface finishes are required, such as toys, kitchen appliances, and musical instruments.

Applications can range from high-volume production of consumer products to low-volume production of industrial parts. The 2K injection molding process methodology allows diverse combinations of material properties to be utilized in the manufacturing process, producing stunning, high-quality products designed to meet specific customer demands in different industrial sectors.

-

5. Challenges and Considerations:

While 2K injection molding offers several advantages over traditional injection molding methods, the process presents some unique challenges and considerations that manufacturers need to take into account. Here are the key challenges:

- Capability of Equipment and Tools: The 2K injection molding process requires specialized equipment, consisting of two injection units and two molds, operating in synchrony. These specialized tools can be challenging to design, produce, and maintain, requiring costly investments in equipment and tools, yet being essential for quality productions.

- Material Selection: Choosing the proper materials to use in a 2K injection molding process is critical to products’ quality, functionally and aesthetically. Material selection can impact the product’s performance, chemical resistance, and ability to withstand wear and tear. Utilizing incompatible materials can lead to production issues, such as bubbles or delamination between layers, resulting in increased material waste.

- Requirement for Skilled Labor: The 2K injection molding process requires skilled technicians to manage and maintain the mold, injection units, and the injection molding process. Training personnel to understand the complexities of the 2K injection molding process, including how to maintain equipment and optimize the process, is essential to achieving high-quality products.

Understanding these challenges and considerations in the 2K injection molding process is fundamental. Addressing such challenges requires proper planning, investment in specialized equipment and tooling technology, as well as skilled labor, to control the manufacturing process, reduce production costs and optimize the outcome.

-

6. Future of 2K Injection Molding:

The future of 2K injection molding looks promising as advances in technology and increased adoption across various sectors promote new possibilities in manufacturing. Here are some future developments predicted for 2K injection molding:

- New Developments in Technology: As technology advances, new processes and materials will emerge, and it will be possible to integrate these developments into the 2K injection molding process. Improvements in the electronics and instrumentations for the 2K injection molding machine will enable better process control, resulting in more precise and efficient injection molding. Further development of 3D printing, nano-technology, and micro molding will also have an impact on the 2K injection molding process.

- Increased Adoption in Industry: As more industries recognize the advantages of the 2K injection molding process, it is expected to see an increase in adoption. The medical and automotive industries are expected to see significant growth as manufacturers increasingly use the 2K injection molding process to produce medical devices and automotive components with complex shapes and high-quality surface finishes. The electronics and consumer goods industries are also expected to adopt 2K injection molding for producing high-quality and sophisticated products.

The future of 2K injection molding looks bright, with new technological developments and increased adoption in various industrial sectors driving innovation and increased efficiency. Thus, advancements in materials, processing, and technologies are anticipated to drive 2K injection molding advancements and proliferation across the manufacturing sectors.

If you need about 2K Injection Molding Services,You can click on the V1 Prototype website to find it.

-

7. Conclusion:

2K injection molding is a highly precise manufacturing process that enables the production of complex designs with a high-quality surface finish. The 2K injection molding process allows manufacturers to produce products with multiple characteristics and properties that would be impossible with traditional injection molding.

The 2K injection molding process offers several advantages, including improved product design, cost savings, and enhanced productivity. The versatility of this process enables its use in various industrial sectors, such as automotive, electronics, medical devices, and consumer goods.

However, the 2K injection molding process also presents challenges, such as the required specialized equipment and tools, material selection, and the need for skilled labor. Overcoming these challenges requires proper planning, investment in equipment, tools, skilled labor, and process optimization.

The future of 2K injection molding is promising, with the expected advancements in technology and increased adoption across various sectors, driving innovation and increased efficiency. As such, 2K injection molding is a critical manufacturing process that is expected to play an essential role in the manufacturing industry’s future.