We delve into the exciting world of 3D printing in construction. We explore the materials used in 3D printing for construction, their properties and potential, and the impact they could have on the industry. We also look at the current state of 3D printing in construction, its limitations, and how it might transform the way we build in the future.

I. Introduction to 3D Printing in Construction

Unveiling the Construction Revolution with 3D Printing

In the ever-evolving realm of construction, a groundbreaking transformation is taking center stage – the advent of 3D printing. This cutting-edge technology has swiftly moved from the periphery to the forefront, introducing novel possibilities and challenging the conventions of traditional construction methods. The ability to craft three-dimensional structures layer by layer, guided by digital blueprints, is ushering in unparalleled advantages and reshaping the trajectory of the construction industry.

Pioneering the Change: A Closer Look at 3D Printing in Construction

To embark on our exploration of the future of construction, it's imperative to comprehend the intrinsic advantages that 3D printing brings to the construction table. Speed, precision, and cost-effectiveness are the linchpins of this transformative technology. Traditional construction methodologies, often laden with time-consuming processes and labor-intensive endeavors, are now under the scrutiny of 3D printing, offering a swifter, more efficient, and economically viable alternative.

II. Materials Used in 3D Printing for Construction

Beyond Concrete: A Material Odyssey in 3D Printing

Reinventing the Foundation: Concrete-Based Materials

Concrete, a staple in construction, takes on a new avatar in the realm of 3D printing. Tailored concrete mixtures designed explicitly for 3D printing bring forth heightened strength and durability. The careful concoction of materials ensures impeccable layer adhesion and structural integrity during the intricate dance of 3D printing.

Polymers in the Limelight

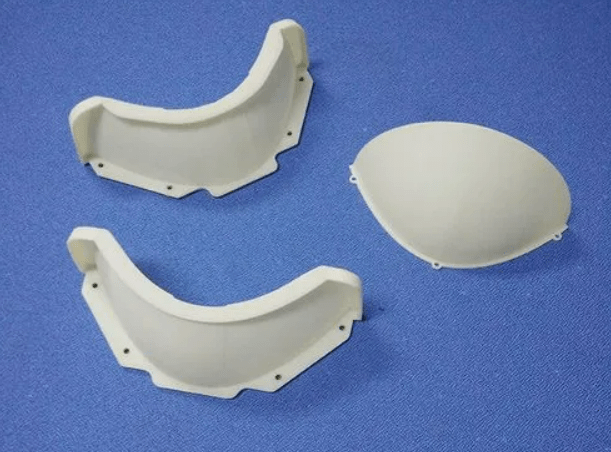

Parallel to concrete, polymer-based materials emerge as pivotal players in the 3D printing orchestra for construction. The versatility of polymers opens doors to tailoring materials to meet specific project requirements. These lightweight materials prove ideal for the intricate dance of creating complex architectural designs without compromising structural robustness.

Eco-Friendly Ascent: Bio-Based Materials

A rising star in 3D printing for construction is the use of bio-based materials. Derived from renewable resources, these materials champion environmental sustainability, reducing the carbon footprint of construction projects. As the industry pivots towards a more eco-conscious approach, bio-based materials garner attention for their earth-friendly attributes.

The Expansive Palette

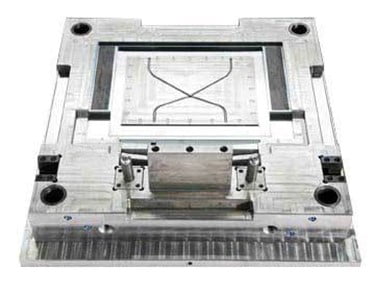

Beyond the trinity of concrete, polymers, and bio-based materials, the landscape of 3D printing for construction is painted with a broad stroke of experimentation. Metals, ceramics, and composite materials join the symphony, each introducing unique properties and applications. This ongoing exploration showcases the adaptability and limitless potential inherent in 3D printing technology.

III. Impact of 3D Printing on the Construction Industry

Engineering Efficiency: The Accelerated Pace of Construction

One of the cornerstones of 3D printing's impact on the construction industry is the revolutionization of efficiency and construction speed. Traditional construction methodologies often involve intricate and time-consuming processes, leading to delays and spiraling costs. 3D printing steps onto the scene as the harbinger of change, facilitating rapid and automated construction that trims project timelines and mitigates labor costs.

Frugality Redefined: Cost Reductions and Material Efficiency

As 3D printing gains prominence in construction, the industry witnesses a tangible shift towards cost reductions. Precision becomes the guiding principle, minimizing material waste by utilizing only the requisite amount for each layer. This not only translates into direct cost savings but also aligns with a sustainable approach, resonating with the industry's burgeoning eco-consciousness.

Unleashing Creativity: Design Flexibility and Customization

The 3D printing canvas offers a spectrum of creative freedom and customization in construction projects. Architects and designers find themselves unshackled from traditional constraints, empowered to create intricate and avant-garde structures that were once confined to the realm of imagination. This newfound liberty unleashes a wave of innovative and aesthetically pleasing architectural designs.

Safety in Progress: Environmental Considerations and Worksite Safety

Safety has always been a paramount concern in construction. 3D printing steps up to the plate by minimizing the need for manual labor in hazardous environments. Furthermore, the integration of bio-based materials and the reduction of construction waste contribute to a more environmentally friendly construction process, aligning seamlessly with global sustainability goals.

IV. Current State of 3D Printing in Construction

Prototypes and Pioneers: The Experimental Landscape

The current state of 3D printing in construction unfolds as a tapestry of prototypes and experimental projects. Researchers and construction visionaries actively probe the boundaries of the technology, conducting experiments to fathom its capabilities and potential applications. This phase of prototyping serves as a crucial crucible for refining and perfecting 3D printing techniques, paving the way for mainstream construction adoption.

Reality Checks: Commercial Applications and Case Chronicles

Beyond the experimental phase, 3D printing has transcended theoretical constructs to manifest in commercial applications. Real-world case studies illuminate the successful integration of 3D printing in constructing houses, bridges, and entire buildings. These tangible applications underscore the feasibility and reliability of 3D printing in a diverse array of construction projects.

Taming Titans: Challenges and Frontiers of 3D Printing in Construction

However, the journey towards ubiquitous adoption is fraught with challenges. Scaling limitations, regulatory hurdles, and the imperative for standardized processes pose formidable obstacles. Overcoming these challenges necessitates a concerted effort from all stakeholders, including researchers, policymakers, and industry professionals, to seamlessly integrate 3D printing into the fabric of mainstream construction practices.

V. The Future of 3D Printing in Construction

The Alchemy of Progress: Advances in Materials and Technologies

The future of 3D printing in construction unfolds as a saga of alchemical progress, particularly in the realms of materials and technologies. Ongoing research endeavors focus on forging advanced materials that marry heightened strength, durability, and environmental sustainability. Concurrently, technological innovations are afoot to enhance printing speed, precision, and scalability, propelling 3D printing into new frontiers.

Fusion Dynamics: Integration with Traditional Construction Methods

While 3D printing stands poised to redefine the construction landscape, it's crucial to recognize its potential as a collaborative force with existing construction methods. The seamless integration of 3D printing with traditional techniques promises hybrid approaches that amalgamate the strengths of both, providing a holistic and efficient construction solution.

A Global Odyssey: Expansion and Embrace of 3D Printing in Construction

As 3D printing technology matures, its global expansion and adoption in construction projects become an inevitability. The allure of cost reduction, enhanced efficiency, and sustainability will drive increased acceptance across diverse markets. Governments, construction conglomerates, and investors are set to play pivotal roles in nurturing the widespread adoption of 3D printing in construction projects on a global scale.

VI. Conclusion

Epilogue: Illuminating the Path Ahead

In summation, the future of construction unfolds within the embrace of 3D printing technology. The march of progress in materials, coupled with the symbiotic integration of 3D printing with traditional construction methods, is sculpting a new topography for the industry. While challenges linger, the tapestry of benefits including efficiency, cost reduction, and sustainability positions 3D printing as a transformative force in the construction sector. As we gaze into the horizon, the collaboration between industry stakeholders and the relentless pursuit of innovation will carve a construction future defined by precision, velocity, and environmental stewardship.